Introduction

Whether you are unfamiliar with packaging equipment or already have experience with multiple systems, you likely have questions about how they operate. In this article, we will examine the process by which a vertical form fill seal (VFFS) machine converts a roll of packaging film into a completed, shelf-ready bag.

Benifit of Vffs Packaging Machine

Our top-tier vertical form fill seal machines offer both simplicity and high efficiency for handling both food and non-food items. Key features include:

• Fast, tool-free changeover – enables packaging of various bag sizes on a single machine. You can switch bag sizes quickly, typically in minutes rather than hours.

• Intermittent or continuous motion – allows for the production of specialized bag styles at a deliberate pace or increase the speed for heightened production throughput.

• Robust stainless steel or washdown construction – ideal for enduring rigorous cleaning and sanitation standards.

• Flexible bag configurations – capable of producing popular bag types such as quad seal and standard pillow bags. Features can be expanded to include zippers, tear notches, options for modified atmosphere packaging, one-way valve applications, and more.

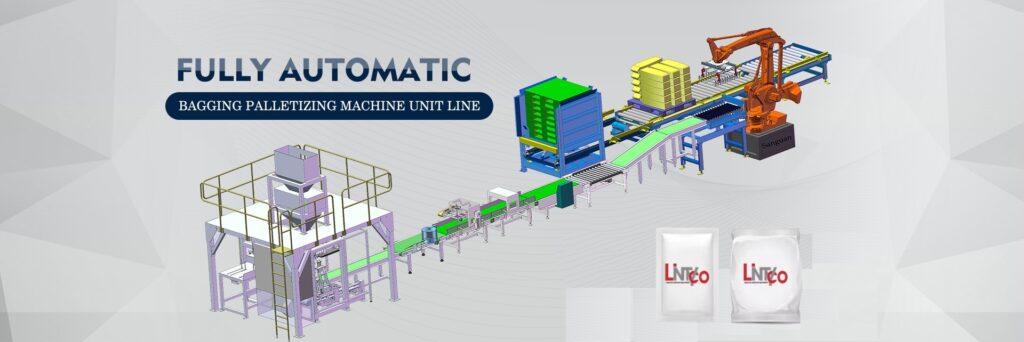

• Seamless integration with other equipment – compatible with leading industry fillers, conveyors, X-ray systems, checkweighers, and solutions for cartoning and case packing.

• Enhanced productivity through streamlined operation processes, reducing downtime and increasing output. • Advanced user interface options that simplify machine operation, allowing for better control and efficiency in production settings.

Type of Vffs Machine

VFFS machines can operate with either an intermittent or continuous motion. The intermittent type has a stop-start motion, where the film feed pauses momentarily. During this stopped period, the stationary end seal unit creates the top and bottom seals.

In contrast, the continuous motion VFFS keeps the film moving constantly without stopping. For this type, the end seal unit itself moves vertically to match the film’s downward travel while sealing the bag ends. This up-and-down motion prevents product from being jarred or damaged by a drop during sealing.

The continuous motion design is preferred for high-speed operations and delicate, fragile products that need gentle handling. The intermittent stop-start model is suitable for products that can withstand some drop impact and do not require ultra high packaging speeds.

Process of Vffs Packaging

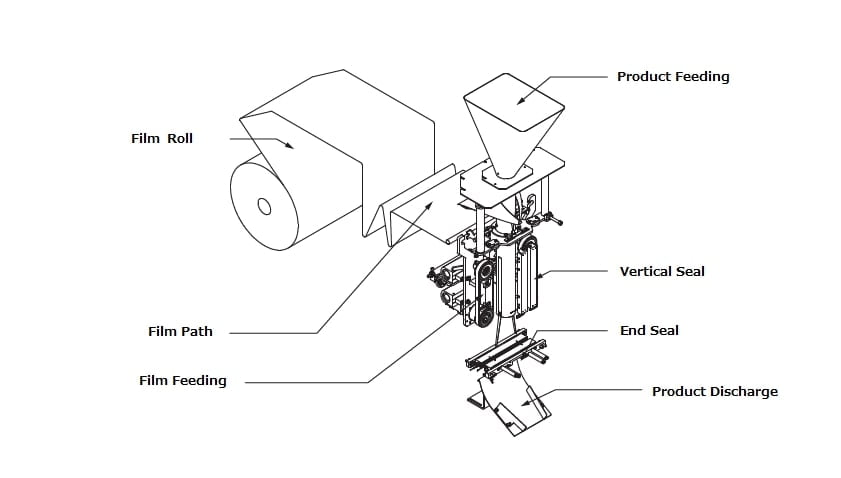

VFFS machines package products in a vertical process using rollstock film.

Film Unwind & Transport A roll of packaging film is mounted on a spindle at the rear of the machine. The film web is pulled off the roll by transport belts that run along the forming tube at the front. An optional power unwind assists with unwinding heavy rolls.

Film Tension & Tracking A dancer arm with rollers applies tension to prevent the film from wandering. The film passes under a registration photoeye that controls the positioning via the transport belts. Film tracking sensors can shift the entire film carriage to keep the edges aligned.

Printing (Optional) An installed printer can apply dates, codes, graphics or registration marks onto the film.

Forming Tube The film enters the forming tube where it is folded around into a tube shape with overlapping edges for sealing into a bag.

Sealing As the formed tube descends, a heated vertical seal bar bonds the overlapping film edges together. Horizontal seal bars then seal across the top and bottom to form the individual bag.

Bag Filling Product is dropped through the forming tube into the open bag top from an integrated filler like a scale or auger.

Discharge After filling, a knife cuts the sealed bag which drops into a receptacle or onto a conveyor. VFFS machines can run at rates of 30-300 bags per minute depending on the format.

Conclusion

Vertical form fill seal (VFFS) machines streamline the packaging process, transforming raw packaging film into finished, shelf-ready bags efficiently and effectively. These machines are versatile enough to handle both food and non-food items with various packaging options, ensuring products are sealed securely and presented attractively. The integration of advanced technology allows for quick changeovers and continuous operation, reducing downtime and boosting productivity. VFFS machines are a crucial component in modern packaging lines, offering robust construction, flexible configurations, and seamless integration with other equipment.

Contact us to get your free vffs packaging solution !