Granule

Granule Packaging Machine

Lintyco is well-versed in the field of food ,beverage and non-food packaging machines. In fact, more than 80% of the machines we produce are used in the food industry. We have developed packaging solutions for a wide range of food items, including small snacks such as jelly beans and gumballs, fresh produce such as apple slices, coffee, organic foods, rice, cheese, sugar, candy,nuts, biscuits and pet food. Our robust packaging equipment is capable of handling food packaging projects of any size, from the smallest to the largest.

we support intimate OEM/ODM services to meet your unique requirements. Welcome to get in touch with us for the best price.

Granule Packaging Machine Choice

ROTATING PREMADE POUCH GRANULE PACKAGING MACHINE

Our Premade Pouch Packaging Machine covers SS304 and adopts German/Japanese electronic components.Package up to 80 Bags/Min. We provide layout drawing service ,OEM service and decent delivery time.

Vertical Form Granule Fill&Seal Packing Machine

Vertical Form Fill & Seal Machine, as a classic solution for Granule packaging, is also one of the choices. Package Up to 60 Bags/Min,Low price .If you have no special requirements for the appearance of the product packaging, then it is a good Choice.

Flow Packing Machine

Horizontal Form Fill & Seal Machine, also as a classic solution for Granule packaging, is also one of the choices. Package Up to 290 Bags/Min, the servo Intelligent control, run with low noise .If you have high special requirements for the accuracy of the product packaging, then it is a good Choice.

Granule Packaging Video

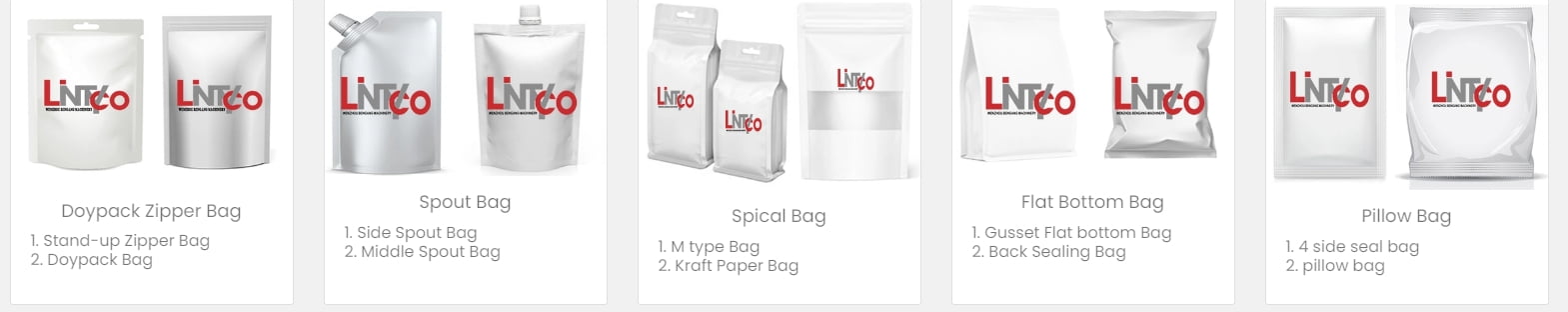

Popular Bag Style

Ultimate Guide

Vertical Form Fill Seal (VFFS) Machines

These machines form the packaging, fill it with the product, and seal it in a vertical manner. because of its high speed and low price,they are ideal for packaging a variety of granular products.

Stick Pack Machines

These machines are perfect for packaging granular products in stick format, commonly used for single-serve packages.Normally granule food will be packed by it.

Multi-lane Sachet Machines

These machines can produce multiple sachets at once, increasing packaging speed and efficiency.It is also useful for powder sachet

Granule Baggers can automatically package many different free-flowing dry granular materials like chemicals, powders, minerals, food ingredients, plastics, ,puffed food, shrimp strip, peanut, melon seed, seed, monosodium glutamate, corn, jelly, sugar, salt, cereal mix, and so on.

Lintyco premade pouch bagger LTC6,LTC8 is ideal choice for granule.

For Low price and high speed,you can choose VFFS bagger

polypropylene/polyethylene aluminum foil/Polyethylene, nylon/Enhanced polyethylene, tea-leaf filtering paper, paper/Polyethylene, etc.

Precision

One of the key advantages is their precision.Lintyco has always been committed to improving accuracy and reducing waste and guaranteeing consistency.Then we have improved the overall accuracy of our automatic packaging machines to1% since the first machine.

Reduced labor and material costs

Using a granule packing machine can reduce labor and material costs associated

Versatility

These machines can handle a variety of granular products such as rice and coffee bean , and offer various packaging formats,like doypack ,flatbottom bag ,4 side seal bag.

Common packaging formats include bags, boxes, cartons, drums and flexible packaging films. Mesh and kraft paper bags are very popular for granules. Auto-sealing options for bags, boxes and pouches are common.

Here is a basic overview of how granule packaging machines work:

Bulk granule storage: Raw materials are stored in large hoppers or silos above the machine.

Dosing/feeding: A feeder mechanism precisely doses the required amount of granules, such as an auger or vibrating tray.

Weighing: Granules are weighed on a high-precision scale to ensure accurate fill quantities. Loss-in-weight or gain-in-weight systems are common.

Filling: Granules are transferred into the packaging via mechanisms like screw conveyors, gravity slides or vacuum filling. Gentler filling avoids granule breakage.

Bag/container sealing: Open bags or other packages are pressed closed and sealed, usually with heat or adhesive. Some machines form-fill-seal in one step.

Quality control: Systems check fill weights, inspect seals/closures and test for leaks to ensure packaging integrity.

Discharge/handling: Filled packages are discharged via conveyors for further handling like labeling, wrapping, box packing etc.

Automation: Advanced machines integrate all steps for non-stop, high-speed production with minimal human intervention.

Small granule packing machine fill 1-10 kg bags at 30-100 bags/hour. vffs fill and seal machines fill 10-25 kg bags at 60-150 bags/hour or 50-1000 kg super sacks at 5-15 sacks/hour. Very high-speed machines fill 1-2 tons/hour.

we support intimate OEM/ODM services to meet your unique requirements. Welcome to get in touch with us for the best price.

Factors to Consider When Choosing a Granule Packaging Machine

When selecting a granule packaging machine, it is important to evaluate several key aspects. The type of granules you need to package should align with the machine’s capabilities – some may perform better for fine or coarse materials. Production needs also matter – ensure the speed satisfies your output requirements. Build quality is essential too – opt for a robustly constructed machine that can withstand continuous use. After-sales support is likewise crucial – rely on a manufacturer committed to sustaining optimal machine performance through reliable servicing over the long run. Comprehensively assessing granule type compatibility, output needs, durability design and aftercare support frames the choice of a granule packager best suited to your operations.

Lintyco is specialize in automatic packaging machine from 2008.our granule packagers are highly automated with integrated weighing systems, bag supply, filling, sealing and discharge conveyors. Some tabletop models require manual bag loading but automate filling and sealing.

Precision depends on the model but most weigh within ±1% accuracy at high speeds. More advanced ones offer microingredients addition and weighing within ±0.1% for quality control.

Regular cleaning and lubrication is needed. Periodic adjustments and parts replacement may be necessary depending on usage. Most reputed brands provide easy access to parts for efficient maintenance.

Here are some tips for maintaining a granule packaging machine:

- Inspect parts routinely for wear and tear. Ensure all moving components operate smoothly and replace or repair as needed.

- When not in use for extended periods, thoroughly clean the entire machine. Wipe down all surfaces and flush any residue from pipes or hoses.

- Protect electrical systems from moisture and corrosion. Keep control panels and terminals clean and dry. Address any electrical issues promptly.

- Maintain sanitary conditions when packaging food-grade products. Follow strict cleaning procedures between changeovers.

- Apply lubricants sparingly to avoid contaminating packaged goods. Use lubricants suited for incidental food contact if required.

- Calibrate weighing and filling mechanisms periodically. Ensure accurate quantity control is maintained over time.

- Inspect safety guards, interlocks and emergency stops regularly. Maintain all safety features in good working order.

- Update machine firmware when applicable. Ensure software is running the latest version for optimal performance.

- Train operators on following maintenance SOPs. Proper upkeep extends equipment life and quality of output.

Download your maintenance list here

Many Factors Influence Granule Packaging Machine Pricing

The cost of a granule packaging machine is affected by numerous variables. Material selection and transportation fees impact expenses, as do taxation and the machine’s technical specifications. Each factor can significantly alter the final price. For example, shipping costs rose sharply in 2021. Additionally, your specific requirements determine pricing, as equipment tailored to varying needs like material type, bag style, production speed and more will have distinctly different price tags. An automated machine, for instance, demands a higher cost than a manual one. Large models also carry a greater price tag than smaller machines. Therefore, clearly outlining your packaging needs is important to obtain the most suitable quote. Providing full details allows us to evaluate all influencing aspects and propose the best priced solution for your setup.

As a leading packing machines manufacturer in China, Bengang Machinery offers a full range of high-performance yet affordable granule packing machines. Our product portfolio also includes a wide variety of liquid and powder packaging equipment. Moreover, our experienced team works diligently to ensure quality products and prompt deliveries. Whether you need a granule, liquid or powder packager, our machinery provides excellent solutions. As a reliable manufacturer, we strive to satisfy all of your packaging equipment needs. If you are searching for a granule packing machine, feel free to contact us. Our representatives will be happy to provide more details about specifications, pricing and delivery options. Bengang Machinery is committed to offering customers the best packaging solutions and services. Please get in touch with us today for all your packaging machinery requirements.