3 Side Seal Bag Packing Machine

3 Side Seal Pouch

- Economically cost

- Ample room for branding and messaging

- Easy to pack into cases

- increased product protection

- Easy open &press; to close

3 Side Seal Bag Packing Machine Choice

VFFS Flat Pouch Packaging Machine

Suitable for Granules,Powder,Liquid and Special material). Film width:420-730mm Capacity:45-60bag/min . Bag size:W(90-350mm) L(20-450mm)

Premade Pouch 3 Side Seal Flat Packaging Machine

Suitable for Granules,Powder,liquid and Special Material. Filling vollum:30-2500g Capacity:25-60 bag/min Big size:W(80-300mm ) L(100-400mm)

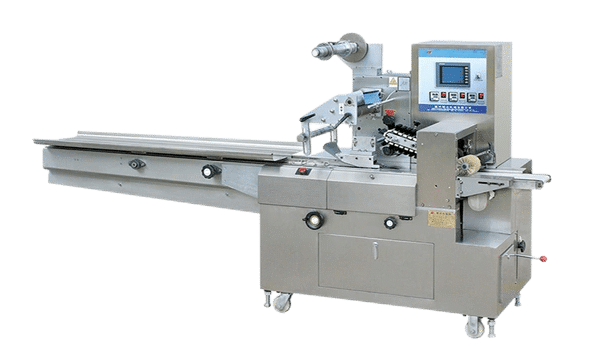

Pillow Form Fill&Seal Packaging Machine

Suitable for any food,commodity,Medical&Healthy industry. Capacity:30-290per/min. Packing Range:(60-400mm) W(35-100mm). Max width of film:300mm

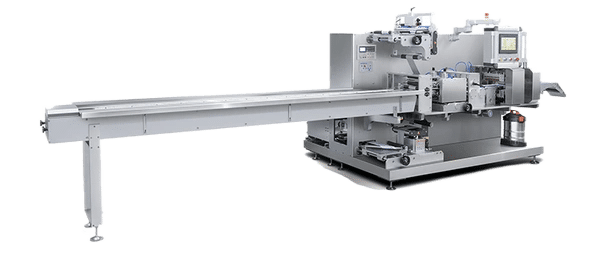

Horizontal Form Fill&Seal Packaging machine

Suitable for food,non-food industry and pharmaceuticals.Capacity:80-120 per/min .Packing Range:L(100-280mm),W(85-160mm) Max width of film:400mm

Bag Desciption

A 3-sided seal pouch is a type of packaging pouch with seals on three sides and one open end, similar to a flat rectangular pocket. It is commonly used to package various goods such as food, coffee, tea, snacks, pet food, and more. Bags can be made from a variety of materials such as plastic, paper and foil. The three-sided flat-sealed design provides excellent barrier protection to maintain freshness, dryness, and protection from external elements. It is a popular packaging option due to its straightforward design, convenience, and cost-effectiveness.

FAQ

3-side seal pouches vary by material, design features, and applications:

- By material:

- Food-grade laminates (PET/PE, PET/Aluminum foil/PE)

- Industrial-grade films (metallized PET, recyclable PE)

- Specialty options like twist-wrap PVC or moisture-resistant BOPP

- Food-grade laminates (PET/PE, PET/Aluminum foil/PE)

- By design:

- Standard flat pouches

- Customizable versions with tear notches, hanging holes, or transparent windows

- Resealable zipper pouches (press-to-close or Velcro)

- Vacuum/freezer-compatible pouches

- Standard flat pouches

These pouches are ideal for:

- Food: Snacks, tea, pet food, spices, frozen items, and vacuum-sealed meats

- Healthcare: Facial masks, pharmaceutical powders, veterinary products

- Industrial: Powders, chemicals, and hardware components

- Retail samples: Single-serve products, trial-size cosmetics, or promotional items

3-Side Seal Pouches | Doypack Bags |

|---|---|

| Lower production cost (single sheet vs. multi-layer construction) | Higher material cost (built-in base for standing) |

| Space-efficient storage (lay flat) | Requires shelf space for upright display |

| Easier filling/sealing (open-top design) | Complex filling due to gusseted base |

| Lightweight and compact (ideal for bulk shipping) | Heavier structure for retail visibility |

| Customizable for vacuum sealing/freezing | Limited to ambient or refrigerated storage |

High-quality Guarantee

We strictly control the quality of every process from raw materials to finished products, use GMI color management system for printing to ensure color consistency.

Our plant has been certified by ISO 9001:2015, ISO 14001:2015, ISO22000:2018, BRC, BSCI, and GMI to ensure high quality and food safety

To guarantee high quality and food safety, the below items are strictly tested in the in-house laboratory:

Learn more

If you have the model you are interested in, please check it machine catalog

if you have the corresponding material, please go to Industry to choose.

If you have interested in another pouch style, please click here to Pouch style

The quickest way to choose the best packing solution is to contact us directly, don’t hesitate!

Free service to help calculating the return on investment of a potential packaging machine purchase? Get it Now!