first-time buyer

Where bold vision meets precision design. Our packaging machines turn ambitions into realities.

If you are considering whether it is time to invest in automated packaging machinery, we can assist you.

Our resources for first-time buyers provide information on various types of packaging machines, tips for making the best automation decision for your business, and answers to common questions about packaging machinery.

Additionally, you can download a PDF list of questions that our packaging machine specialists use during consultations to prepare for your first call with us.

Popular First-Time Packaging Machines

HFFS Packing Machine

1. Up to 290 Bag/min 2. With the servo Intelligent control, run with low noise 3.OEM&ODM is allowed 4. Decent time for delivery

Premade Pouch Packaging Machine

1. Up to 80bag/min 2.apply for ready bag such as zipper bags, stand-up bags, doypack, side spout bags...etc. 2. machine covered SS304 and adopt high-quality electronic components. 3. Decent time for delivery

Frequently Asked Questions

The packaging machine is a collection of mechanical, aesthetic, and practical products. The specific processes include transferring material, filling, bagging, sealing, and coding. A good packaging machine is about high precision and cost-effectiveness. See below for details:

We should know the product material type that you want to pack

Cost-effectiveness is the first Principle. Keep in mind that the cheapest option may not always be the best choice.

Try to look for a supplier who has a good reputation and a legitimate business license.

Better to have plan to visit the factory and pay more attention to the machine, especially machine detail, machine quality always depends on detail, better do machine test with real sample products.

Consider their after-sale services: After-sale services such as technical support, repair, and maintenance are essential to the longevity and productivity of your packaging machines. Make sure the supplier offers these services and has a good reputation for customer support.

products type, solid products specific sizes

Bag sizes and type with pictures

Packing weight

Packing speed, capacity

Special requirements, such as filling Nitrogen, exhausting, zipper close, date printing

Power supply voltage, Frequency

Factory workshop, Height limited.

Powder —— caking condition, damp, solid mix

Liquid —— liquid temperature, paste or liquid, liquid volume, if need filing by twice

。

The cost of packaging equipment varies depending on the type of machine, its capabilities, and the manufacturer. Generally, prices can range from a few thousand dollars for a basic machine to hundreds of thousands of dollars for a high-capacity, fully automated system.

The answer to this question depends on the specific packaging machine in question. Some machines are designed to handle a wide range of bag styles, sizes, and products, while others are more limited in their capabilities. It is important to carefully consider the needs of your business and the types of products that you will be packaging when selecting a machine. Additionally, you may want to consult with a packaging machine specialist to discuss your specific requirements and determine the best machine for your needs.

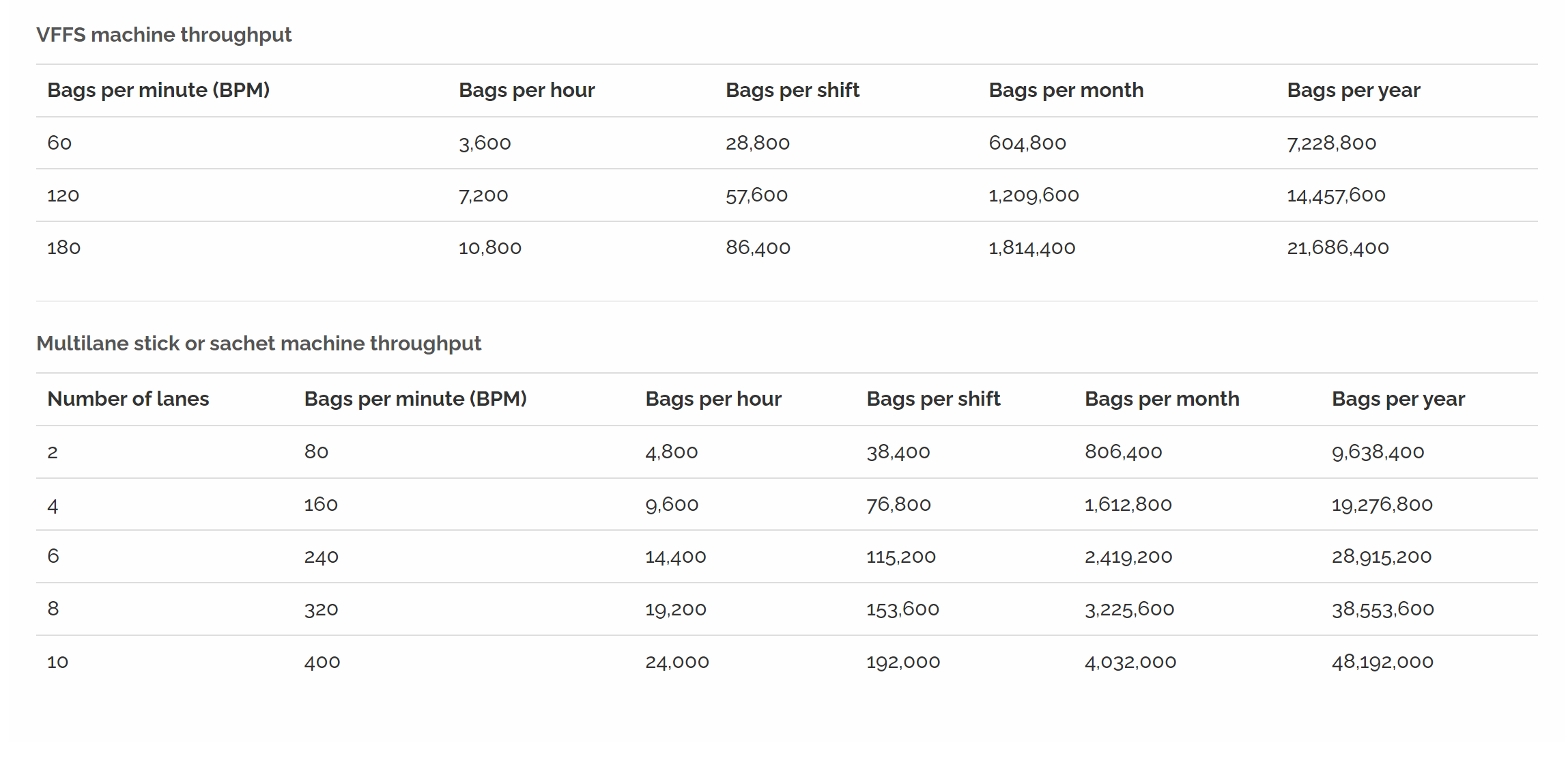

Determining whether your production needs are high enough to make packaging automation worth it can be a complex process. Factors to consider include the volume of products that you are packaging, the speed at which you need to package them, and the level of consistency and accuracy that is required. In general, if you are currently using manual packaging methods and are experiencing inefficiencies, errors, or quality control issues, it may be worth considering automated packaging machinery. Additionally, if you are experiencing a significant increase in demand for your products or are looking to scale your business, automated packaging machinery may be a good investment. It is important to carefully evaluate your specific needs and requirements in order to determine whether automated packaging machinery is right for your business.

4 Top Resources

QUESTIONS TO PREPARE FOR

To ensure that the packing machine we recommend is ideal for your needs, we typically conduct initial conversations that involve asking a series of questions. Get ahead of the game! Download our free list of discovery questions to begin planning for successful packaging automation.

BEFORE REQUESTING PRICING

Thinking about contacting a packaging machine manufacturer for pricing? Make sure you’ve gathered all the necessary information before you start. Read about the 5 most crucial pieces of data we need to provide the most precise pricing as part of your equipment proposal.

PREPARE YOUR FACILITY

How do you get your facility ready for new packaging equipment? It may require more effort than you think. But don’t worry, we’ve got you covered with a simple list of items to prioritize when preparing for new machinery.

THE NUMBERS DON'T LIE

Calculating machine return on investment can involve some effort, but it’s essential for determining if packaging automation is a worthwhile investment for your business. Let our free calculator do the work for you.

Learn More About Packaging Equipments

Get your Free First-time Buyer's Guidebook

Our experts break down everything you need to know to choose the most suitable packaging equipment for your business