Snack packaging Machine

Sample bag

Machine Choice

Rotating Premade Snack Pouch Packing Machine

Lintyco Premade Pouch Packaging Machine covers SS304 and adopts German/Japanese electronic components.Package up to 80 Bags/Min. We provide layout drawing service ,OEM service and decent delivery time.

Vertical Form Snack Fill&Seal Packing Machine

Vertical Form Fill & Seal Machine, as a classic solution for Granule packaging, is also one of the choices. Package Up to 60 Bags/Min,Low price .If you have no special requirements for the appearance of the product packaging, then it is a good Choice.

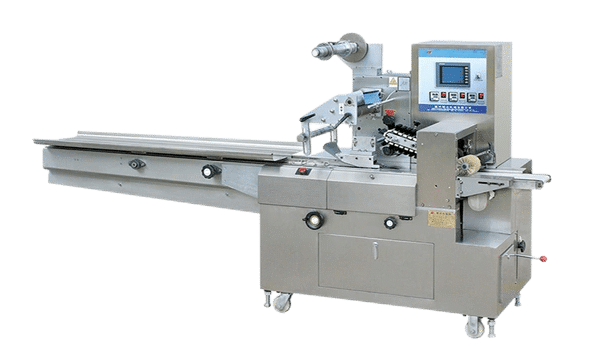

Horizontal Flow Pack Wrapper For Snack

The snack flow wrapper machine, a classic solution for Granule packaging, is also one of the options.Package up to 290 bags per minute with the intelligent control system. It runs quietly and is a great option if you need precise candy packaging.

Ultimate FAQ Guide

- Chip varieties like potato, tortilla, and pita can be placed consistently in bags or boxes to benefit from consistent packaging. Baked goods like cookies, biscuits, and wafer sticks are packaged in sturdy packaging.

- Nuts like almonds, peanuts, cashews, and pistachios flow smoothly into pouches, trays, or canisters with precision. Cheese snacks, saltine crackers, and graham crackers are all securely sealed.

- Dried fruits like raisins, apricots, and cranberries are protected and neatly portioned. Mixes that involve trail mixes, party mixes, or granola combinations fall under the machine’s vast capabilities.

The snack packaging system combines the functions of key internal systems to seamlessly coordinate complex operations.

The transmission system, which includes motors, belts and linkages, precisely synchronizes physical movements according to production mandates. An embedded programmable controller directs workflow sequences in real-time.

This packaging module can perfectly package snacks in various formats like bags or boxes. Material supply mechanisms are reliable and can deliver packaging material on time.

In-line detection technologies, from check weighers to label verifiers, keep a close eye on compliance throughout the process. As needed, real-time data feeds back corrective adjustments.

Safety features like guards and e-stops keep operators safe while allowing them to continue operating. Their safekeeping is what makes machinery dependable.

The combination of these core mechanisms creates the automatic transformations that packaging demands. Snacks’ journey is complete with integrated choreography and precision packaging.

Thanks to the integration of mechanical, electrical, and digital domains, we can automate tasks that would otherwise require a lot of manual effort. The end-consumers are benefiting from this technological wizardry every day.

The working process of snack fill and seal machine is to input snacks from the feeding system to the packing system first, after the packing process, the snacks will be packed and finally tested by the testing system to see if they meet the requirements and rejected if they do not.

Firstly, snacks are introduced to the system via a feeding mechanism which regulates intake. This primes the items for subsequent handling.

Following initiation, a packing module expertly portions and encloses snacks in the designated format. Through full automation, bags, boxes or other containers are populated.

After the packing stage, quality inspection takes place. Compliance testing subjects each unit to verification protocols. Items meeting standards pass downstream while non-conforming products are automatically rejected.

Real-time monitoring threads through this process whereby deviations may trigger adjustment. Furthermore, equipping guarding secures safe operation.

The price of snack food packing machine will vary according to different manufacturers and configuration and other factors, specifically between hundreds of thousands of yuan to millions of dollars.

Considerations Shaping Snack Packaging Investment Levels

The financial requirements for automated snack packaging equipment can fluctuate meaningfully based on a variety of influential metrics.

More basic or customized smaller footprint solutions may represent five-digit investments in some currencies. However, sophisticated robotic lines or fully integrated turnkey systems typically demand six-digit price tags or higher.

Naturally, the supplier’s reputation and experience impacts pricing, as premier brands commonly charge premium rates. Additionally, the scope of validation services influences budget forecasts.

Single-function packaging units focusing on a solitary task achieve more affordable points than multi-stage configurations. Likewise, specialized additions from printing to inspection augment final costs.

Total expected volumes also shape investment needs, with high-speed capabilities for thousands of items hourly necessitating sizeable high-tech investments. Complex formats further influence budgets versus basic bagging.

Through understanding unique project parameters and competitive alternatives, Lintyco Packing Machine manufacturer can determine optimally cost-efficient packaging solutions tailored to their production goals and investment tolerance levels. A nuanced evaluation guides spending accordingly.

The service life of the snack packaging machine varies according to the quality and maintenance of the machine and many other factors, generally between 5-10 years.

Key Factors in Selecting the optimal Snack Packaging Equipment

Choosing a snack packaging machine requires evaluating multiple important criteria to ensure the best fit. Consider:

Throughput capabilities: Confirm the unit can reliably handle projected volumes without compromising quality control.

Packaging formats: Determine needs like pouches, trays etc. based on snack attributes and marketing strategy.

Versatility: Search for adaptable solutions accommodating variable sizes, shapes and material types over the lifecycle.

Durability and reliability: Source equipment from reputable OEMs with a solid track record of resilient, dependable constructions.

After-sales support: Assess vendor support infrastructure including application expertise, spare component availability and warranty terms.

A holistic evaluation of these critical factors helps identify packaging solutions optimally tailored for specific production needs, budgets and versatility demands. Factoring long-term operational requirements into decisions leads to maximum return on sizeable capital investments.

There are various snack packing machines available, designed to meet different packaging needs. . Some common types include:

– Vertical form-fill-seal (VFFS) machines: Ideal for packaging snacks in pouches or bags, offering versatility in bag sizes and styles.

– Horizontal form-fill-seal (HFFS) machines: Suitable for packaging snacks in flat or stand-up pouches, providing excellent product visibility.

– Multi-head weighers: These machines accurately weigh and dispense snacks into individual packages, ensuring consistent portion sizes.

– Tray sealing machines: Used for packaging snacks in trays or containers, offering tamper-evident seals and attractive presentation.

– Vacuum packaging machines: These machines remove air from the packaging, creating a vacuum seal that helps preserve snack freshness.

Here are some tips to keep snack packaging machinery performing at its best:

-Step away from the area and thoroughly clean it to prevent any issues with operations.

-Don’t forget to follow the OEM’s lubrication protocols for smooth component interplay.

-Regularly check for and replace deteriorating parts.

-Make sure the operators get guidance on how to operate and follow safety protocols.

-Make sure to follow the factory’s maintenance schedule and get specialist help for any repairs that need it.

Proper preservation practices help ensure longevity and reliability. Deep-cleaning is scheduled to eliminate any residue accumulations. Good lubrication helps dynamic parts wear less. By thoroughly examining things, we can catch small issues before they become big problems. Well-trained personnel can minimize downstream challenges. With careful preventative care, our packaging output stays consistent over the long haul.

You can check the maintence list Here