Premade Pouch Filling

Pouch Filling Machine

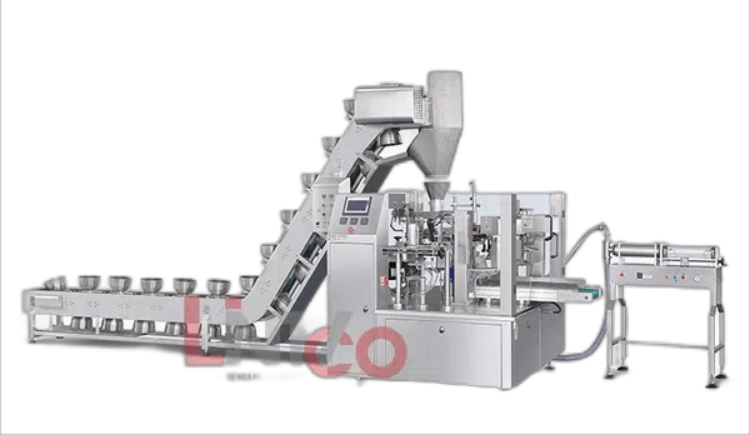

Starting with the turnkey packing system, we have the LTC pre-made pouch-filling machine that is designed for production rates of up to 3600 bags per hour. The Junior automatically opens, fills and seals pre-made stand-up pouches in one process, making it easy to use and extremely compact. Its features include stainless steel frame, Omron PLC, colour touchscreen, vacuum generator and no bag – no fill sensor.

At Lintyco, we offer highly accurate pouch-filling solutions for various bags, including doypack bag with zipper, stand-up bag,3 side bag,4 side bag and back seal bag.OEM and ODM is avaliable for your products.

Automatic Pouch Filling Machine Choice

Depending on the product, different pouch packaging technologies are suitable for packaging foodstuffs and other products. Discover our series for the packaging industry.

SOLID POUCH PACKING MACHINE

DoyPack zipper bag granule packaging machine is specially used for granular/solid food and commodities, such as nuts, rice, potato chips, candies, snacks, pet food, crystal MSG, granular medicines, capsules, seeds, chemical raw materials, sugar, chicken essence, melon seeds, pesticides , chemical fertilizer...etc.

Our Premade Pouch Packaging Machine covers SS304 and adopts German/Japanese electronic components.Packing machine can work with different filler to pack solid, powder and liquid.Package up to 80 Bags/Min. It is best choice in the long time.

LIQUID POUCH PACKING MACHINE

DoyPack Pouch Liquid Packing Machine special for detergent, Yellow rice wine, Milk, Water, Washing Fluid Soy sauce, Rice vinegar, Juice, Tomato paste, Peanut paste, Fruit paste, Chili sauce, Bean sauce, etc. This machine is the first choice for packaging liquids, especially viscous liquids.

POWDER POUCH PACKING MACHINE

Powder premade pouch packing machine special for powder such as Coffee powder, Flavoring, MSG, Chill spicy powder, Milk powder, Glucose, Washing powder, Raw chemistry material, White sugar, Pesticides, Fertilizers, etc..If you have high special requirements for the accuracy of the product packaging, then it is a good Choice.

POUCH PACKING MACHINE FOR SPECIAL MATERIAL

Speical Product Packing Machine special for something such as shisha, pickles, chicken ,kimchi and ready meal.....etc.

Doypack Packing Machine Video

How To Find Your Idal Pouch Packing Machine In 4 Easy Steps

Selecting the right pouch filling technology is important for optimal operations. Lintyco’s extensive portfolio matches specific industry and application requirements.

Begin by specifying your market sector. This provides solutions tailored for that industry’s unique needs.

Next, identify your intended usage. Applications have distinct characteristics requiring purpose-built performance.

Experienced users may opt to filter by equipment varieties. You can focus searches to certain product types, engineering designs or series familiar to your work.

Get to know precise technical and Refine results further using pumping speeds, volumes or other operational metrics important to your process parameters.

4 Top Benifit

Reduce energy consumption

Save on maintenance costs

Our commitment to customer satisfaction extends beyond the purchase of our packaging machines. We offer comprehensive after-sales support, including installation, training, and ongoing maintenance services. Our team of skilled technicians is readily available to address any issues or concerns you may have. Additionally, we provide regular maintenance programs to ensure the optimal performance and longevity of your machine. With our robust support system, you can have peace of mind knowing that we are here to assist you throughout the entire lifespan of your packaging machine.

Ensure product quality and safety

Product quality and safety are our utmost priorities. Our packaging machines are meticulously engineered with robust safety features and quality control mechanisms. We have implemented stringent standards and procedures to ensure that each packaged product meets the highest quality standards. From advanced sensors that detect inconsistencies to automated systems that monitor packaging integrity, our machines underpin a reliable process that safeguards your products. Moreover, our machines are designed to reduce the risk of contamination and maintain product freshness, providing peace of mind when it comes to product quality and safety.

Small-scale businesses

We understand that small-scale businesses face unique challenges and requirements. That’s why we offer a range of packaging machines that cater to businesses of all sizes. Our machines are not only capable of handling high-volume production but can also be adjusted to accommodate smaller production runs. We provide cost-effective solutions that are tailored towards the needs of small-scale businesses without compromising on quality or performance. With our machines, even small-scale businesses can access advanced packaging technology to enhance their operations and compete in the realm of packaging.

Application&Solution

Frequently Asked Questions

The pouch packaging method involves using flexible pouches made of various materials, such as plastic films or laminates, to package products. These pouches are sealed on multiple sides to create a contained package for a wide range of items, including food, beverages, pharmaceuticals, and more.

The pouch packaging system typically includes a pouch filling machine that automates the process. First, the empty pouches are loaded into the machine. Then, the product is dispensed into the pouches, either manually or using automated mechanisms. The pouches are then sealed, usually through heat sealing or zip-lock mechanisms, to ensure product freshness and prevent leakage. Finally, the filled and sealed pouches are discharged from the machine for further processing or distribution.

Foodstuffs can be packaged in pouches through various methods. Dry food items, such as snacks or cereals, are often directly filled into pre-formed pouches and sealed. For liquid or semi-liquid food products, the pouches can be filled using specialized liquid filling machines that ensure accurate and controlled dispensing. The pouches are then sealed to maintain product freshness and prevent contamination.

Vacuum is commonly used in the packaging process, particularly in applications where the removal of air is necessary. Vacuum packaging helps extend the shelf life of perishable products by reducing oxygen levels, inhibiting the growth of microorganisms, and preventing spoilage. It is often utilized in the packaging of food products, such as meats, cheese, and coffee, to preserve freshness and enhance product quality.

Pouch packaging plays a significant role in the food industry due to its versatility and convenience. It is used for packaging a wide range of food products, including snacks, condiments, sauces, ready-to-eat meals, and beverages. Pouches offer benefits such as portability, portion control, and product visibility. Additionally, they can be designed with features like easy-open seals, resealable options, and customizable shapes and sizes to cater to specific food packaging requirements.

A pouch liquid packaging machine is specifically designed to handle liquid or semi-liquid products. The machine typically includes a liquid filling system equipped with precision pumps or nozzles to accurately dispense the desired volume of the liquid into the pouch. The pouches are then sealed, ensuring that the liquid contents are securely contained. The machine may also incorporate additional features such as cleaning and sterilization processes to maintain hygiene during packaging.

A vacuum medical devices packaging machine is used to package medical devices in a sterile and controlled environment. The machine creates a vacuum within the packaging chamber, removing air and minimizing the presence of contaminants. The medical devices are then placed in the packaging, and the chamber is sealed to maintain the vacuum. This packaging method helps ensure the integrity and sterility of the medical devices until they are ready for use.

Vacuum forming is used to thermoform plastic cavities or pockets for blister packaging. The packaging is commonly sealed with cardboard, an aluminum foil lidding seal, or printed plastic film. This film allows product information or branding to be displayed.

Blister packaging offers the benefit of displaying a product while also preventing contact with external factors such as humidity, contamination, and tampering. If opaque blisters are used, the packaged item can be further protected against UV rays.

Blister packs are frequently employed as single-dose packaging for pharmaceuticals like tablets and capsules. They are also commonly used for small consumer goods and food items. The rigid, secure pockets help maintain product integrity during storage and shipping.

Overall, blister packaging provides both protective properties and marketing possibilities through visible product display. It represents a versatile solution for a variety of items that require tamper-proof and shelf-stable characteristics.

When purchasing a pouch filling system, several key points should be considered. These include the desired production capacity, the types of products to be filled (dry, liquid, or semi-liquid), the required accuracy and consistency of filling, the packaging material compatibility, the ease of operation and maintenance, the level of automation desired, and the availability of after-sales support and service.

An integrated pouch packaging solution offers several benefits. It streamlines the packaging process by combining various functions, such as filling, sealing, and labeling, into a single system. This reduces the need for multiple machines and minimizes manual handling, increasing efficiency and productivity. Integrated solutions also ensure better compatibility between different packaging components and improve overall system reliability. Additionally, they often come with advanced controls and monitoring systems, allowing for precise adjustments and quality assurance throughout the packaging process.