4 Side Seal Bag Packing Machine

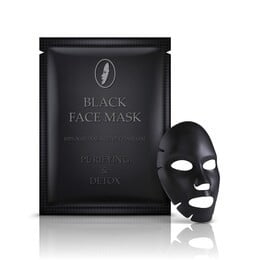

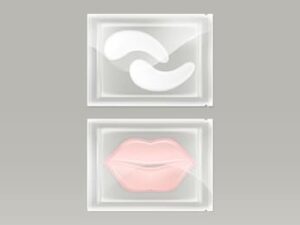

4 side seal bag

- Seal all sides for flat, rectangular shape

- Varied closures (zippers, tear notches, resealable)

- Allow greater space for branding

- Safeguard contents from moisture, air and contaminants

- Constructed from various materials like laminates, foils and polymers

- Popular in food industry due to convenience, durability and protection

4 Side Seal Bag Packing Machine Choice

As specialists in packaging machine manufacturing,we are confident in our ability to determine the optimal packaging solution for your needs. If you select stand up pouches, we would suggest the following machinery for packaging:

Vertical Form Fill&Seal Packaging Machine

Suitable for Granules,Powder,Liquid and Special material). Film width:420-730mm Capacity:45-60bag/min . Bag size:W(90-350mm) L(20-450mm)

Premade Pouch Packaging Machine

Suitable for Granules,Powder,liquid and Special Material. Filling vollum:30-2500g Capacity:25-60 bag/min Big size:W(80-300mm ) L(100-400mm)

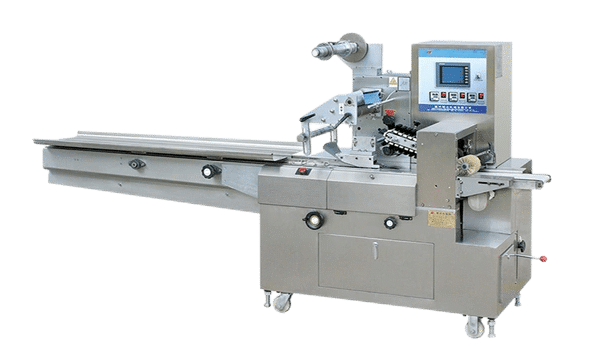

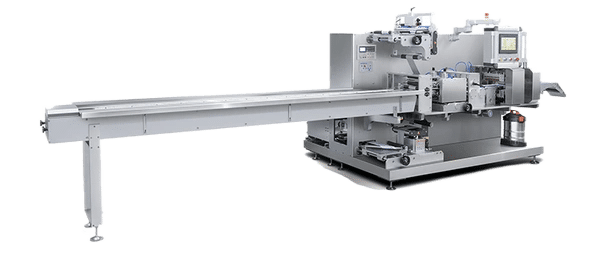

Pillow Form Fill&Seal Packaging Machine

Suitable for any food,commodity,Medical&Healthy industry. Capacity:30-290per/min. Packing Range:(60-400mm) W(35-100mm). Max width of film:300mm

Horizontal Form Fill&Seal 4 Side Seal Packaging machine

Suitable for food,non-food industry and pharmaceuticals.Capacity:80-120 per/min .Packing Range:L(100-280mm),W(85-160mm) Max width of film:400mm

Bag Description

Four-side seal bag is a form of packaging employed to store and transport many kinds of goods such as snacks, powders and liquids. It is constructed by sealing the bag on all four sides, resulting in a rectangular shape that is flat and easy to manage. The bag is usually made of a pliable material such as plastic or foil, and can incorporate various closures like zippers, tear notches, and resealable alternatives.

FAQ

4-side seal bags (quad seal bags) can be categorized based on structure, material, and functionality:

- By Structure:

- Standard Quad Seal Bags: Four sealed edges with a flat base for stability

- Gusseted Quad Seal Bags: Expandable sides for increased capacity

- Stand-Up Quad Seal Bags: Reinforced base for upright shelf display

- Standard Quad Seal Bags: Four sealed edges with a flat base for stability

- By Material:

- Plastic Laminates: PET/PE, OPP/PE for lightweight products

- Aluminum Foil Laminates: Superior barrier properties for moisture-sensitive items

- Recyclable/Compostable: PP/RCPP or kraft paper for sustainability

- Plastic Laminates: PET/PE, OPP/PE for lightweight products

- By Functionality:

- Zipper-Seal Quad Bags: Resealable closures for multi-use

- Window Quad Bags: Transparent panels for product visibility

- Printed Quad Bags: Custom branding with high-resolution graphics

- Zipper-Seal Quad Bags: Resealable closures for multi-use

- Plastic Films: PET, PE, OPP, and nylon for flexibility and moisture resistance.

- Barrier Laminates: Aluminum foil or metallized films for oxygen and UV protection.

- Eco-Friendly Options: Recyclable PP, compostable kraft paper, or biodegradable films.

- Specialty Layers: Anti-static coatings for electronics or odor-resistant films for food.

4-side seal bags are versatile for:

- Food: Snacks (chips, nuts), coffee beans, pet food, and frozen goods

- Liquids/Semi-Liquids: Sauces, honey, and beverages (with spout attachments)

- Retail/Consumer Goods: Cosmetics, tea, pharmaceuticals, and hardware components

- Industrial: Chemicals, granules, and automotive parts

Standard Specifications:

- Dimensions: Width (80–160 mm), length (100–300 mm)

- Thickness: 80–200 microns for durability

- Seal Type: Heat-sealed or ultrasonic-sealed edges

Customization Options:

- Printing: Full-color logos, QR codes, or product information

- Functional Add-ons: Zippers, tear notches, hang holes, or windows

- Material Modifications: Adjust layers for barrier requirements (e.g., UV-resistant films)

- Shape: Unique die-cut designs for branding

- Superior Protection: Four sealed edges prevent leaks and contamination.

- Shelf Stability: Flat base allows upright display, maximizing retail visibility.

- Cost Efficiency: Reduced material waste compared to rigid packaging.

- Sustainability: Recyclable materials align with eco-friendly initiatives.

- Brand Appeal: High-quality printing enhances product recognition

| 4-Side Seal Bags | 3-Side Seal Bags |

|---|---|

| Four heat-sealed edges for reinforced strength | Three sealed edges (two sides + top/bottom) |

| Flat/square base for upright storage | Lay-flat design requiring external support |

| Higher capacity with expandable gussets | Limited volume due to flat structure |

| Ideal for heavy/bulk items (e.g., pet food) | Better for lightweight, compact products (e.g., snacks) |

| Higher production cost (more material/seals) | Cost-effective for simple packaging needs |

High-quality Guarantee

We strictly control the quality of every process from raw materials to finished products, use GMI color management system for printing to ensure color consistency.

Our plant has been certified by ISO 9001:2015, ISO 14001:2015, ISO22000:2018, BRC, BSCI, and GMI to ensure high quality and food safety

To guarantee high quality and food safety, the below items are strictly tested in the in-house laboratory:

Learn more

If you have the model you are interested in, please check it machine catalog

if you have the corresponding material, please go to Industry to choose.

If you have interested in another pouch style, please click here to Pouch style

The quickest way to choose the best packing solution is to contact us directly, don’t hesitate!

Need help calculating the return on investment of a potential packaging machine purchase? We’re here to help.