When it comes to cheese packaging machines, there are several considerations to keep in mind:

First Thing To Know

Type of cheese:

Different cheeses need different packaging methods. Soft cheeses like brie and camembert require different techniques than hard cheeses like cheddar and gouda. When selecting packaging, consider the cheese’s consistency, moisture content, and shape.

Block Cheese

Block cheese is cheese formed into solid blocks and typically sold that way. Here are some features of block cheese:

- Versatile – Block cheese can be easily sliced, grated, or melted based on cooking needs.

- Long Shelf Life – The shape gives block cheese a longer shelf life than other cheeses because less surface area is exposed to air.

- Diverse Flavors and Textures – Block cheese comes in many flavors and textures, from mild cheddar to aged Parmesan.

- Good for Snacking and Cheese Boards – The shape of block cheese makes it easy to slice or cube for snacking or arranging.

Food packaging machines can portion, wrap, and seal block cheese to keep it fresh and make it easy to distribute.

Sliced Cheese

Sliced cheese refers to cheese that has been pre-cut into uniform slices for convenience. Here are its features:

- Convenience: Sliced cheese saves time and effort in the kitchen, as it is ready to use without the need for additional slicing.

- Consistency: Sliced cheese ensures consistent thickness in each slice, providing even distribution and melting when used in sandwiches, burgers, or wraps.

- Portion Control: Sliced cheese allows for portion control, making it easy to estimate the amount used in recipes or for individual servings.

Shredded Cheese

Sliced cheese is cheese that has been pre-cut into uniform slices for convenience. Here are features of sliced cheese:

- Saves Time – Sliced cheese is ready to use without needing to slice it, saving effort in the kitchen.

- Consistent Thickness – Each slice has the same thickness, allowing for even melting and distribution in sandwiches, burgers, etc.

- Aids Portion Control – The pre-sliced form makes it easy to estimate amounts for recipes or individual servings.

Soft Cheese

Soft cheeses have high moisture content and a creamy, spreadable texture. Features of soft cheese:

- Spreadable Texture – The creamy texture makes soft cheeses like Brie, Camembert, and Goat Cheese ideal for spreading on breads, crackers, and bagels.

- Mild, Tangy Taste – Soft cheeses tend to have a mild yet tangy flavor profile that appeals to many people.

- Versatile – The soft, creamy texture makes these cheeses versatile to use in salads, pasta dishes, desserts, and more.

Food Packaging Machines can gently handle delicate soft cheeses to maintain their texture and flavor.

Packaging materials

Pick packaging materials suited to the cheese type and desired shelf life. Common options are:

- Vacuum-sealed bags – Remove air to help preservation.

- Shrink wrap – Tight plastic film conforms to shape.

- Modified atmosphere packaging (MAP) – Replaces air in package with gases to maintain freshness.

Automation level

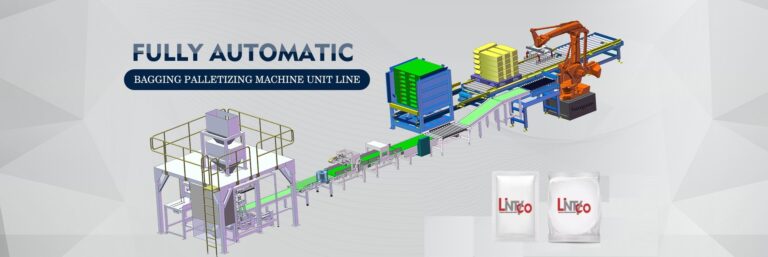

Depending on how much cheese you produce and how efficient you want the packaging process, consider if manual, semi-automatic or fully automatic cheese packaging machines work best for you:

- Manual machines: Lowest cost but lowest efficiency. Requires more labor.

- Semi-automatic machines: Moderate throughput and efficiency. Lower labor requirements.

- Fully automatic machines: Highest throughput and efficiency but highest initial cost. Requires minimal labor.

Quality control

Make sure the packaging machine has features to control quality, like:

- Check weighing – Checks the weight of the cheese to ensure correct amounts.

- Metal detection – Uses magnetic fields to detect any metal contaminants in the cheese.

• Vision systems – Uses cameras to detect visual defects or foreign objects in the cheese and packaging.

These quality control features help catch any issues or contamination during the packaging process, ensuring a safer, higher quality final product.

What Types of Cheese Packing Machines are Available?

Different types of cheese packaging machines, such as vacuum sealers, form-fill-seal machines, and automated cheese slicing and wrapping systems.

Vacuum Sealers:

Vacuum sealers remove air from the package before heat sealing. This helps prolong the shelf life of cheeses like hard cheeses and block cheese. Without oxygen, moulds and bacteria cannot grow as quickly inside the package.

Form-Fill-Seal Machines:

These machines form, fill and seal packages in an integrated, continuous process. They are ideal for packing soft and shredded cheeses. The packaging material is formed into a tube, filled with cheese and then sealed automatically in intervals.

Automated Slicing and Wrapping Systems:

These systems can automatically slice blocks of cheese into consistent slices, and then place the slices into pre-formed film packages before sealing. They offer high-speed, accurate slicing and portioning of cheese for packaging needs.

What Are the Benefits of Using Automatic Cheese Packing Machinery?

- Using a cheese packaging machine offers several advantages:

- Increased efficiency: Packaging machines automate the process, reducing manual labor and increasing packaging speed and efficiency.

- Consistent portioning: Machines ensure consistent portion sizes, providing uniformity in packaging and portion control for consumers.

- Product protection: Packaging machines tightly seal the cheese, protecting it from air, moisture, and contaminants, which helps maintain its freshness and quality.

- Extended shelf life: Properly sealed packages created by packaging machines help extend the shelf life of the cheese, reducing food waste and increasing product availability.

- Improved hygiene: Cheese packaging machines are designed with hygiene standards in mind, minimizing the risk of contamination and ensuring compliance with food safety regulations.

Tricks & Hacks

Now, let’s dive into some tricks and hacks related to cheese packaging machines:

Proper sealing techniques

Ensure the cheese packaging machine has adjustable temperature and sealing time controls to achieve optimal seal strength without damaging the cheese. This will help maintain freshness and prevent air or moisture infiltration.

Flexible portioning options

Look for a packaging machine that allows for flexible portioning, enabling you to pack various cheese sizes and weights. Adjustable forming tubes or molds can provide versatility in portioning.

Easy cleaning and maintenance

Opt for a machine with removable parts and easy-to-clean surfaces to simplify maintenance and prevent cross-contamination between different cheese types.

Integration with labeling and date coding

Consider a packaging machine that can integrate with labeling and date coding systems. This ensures accurate product labeling and traceability, reducing the risk of errors.

Customizable packaging designs

If branding and product presentation are essential, cheese packaging machines can be customized to meet specific packaging requirements. Manufacturers often offer options for different packaging materials, sizes, and sealing methods. Customizations may involve adjustments to portioning settings, sealing mechanisms, or additional features to accommodate unique cheese products.

How do I choose the right cheese packing machine for your business?

When selecting a cheese packaging machine, consider the following factors:

- Packaging requirements: Determine the specific packaging needs of your cheese products, such as portion sizes, packaging materials, and sealing methods.

- Production volume: Choose a machine that can handle your desired production volume efficiently without compromising packaging quality.

- Packaging versatility: Look for machines that offer flexibility to handle different cheese types, sizes, and packaging formats.

- Reliability and durability: Select a machine from reputable manufacturers known for producing reliable and durable equipment.

- After-sales support: Consider the availability of technical support, spare parts, and training offered by the manufacturer.

How to Optimize Cheese Packing Efficiency and Productivity?

Automate packaging processes – Fully automatic packaging machines offer higher speeds, precision and consistency compared to manual packaging. They reduce labor costs and waste while improving throughput.

Reduce non-value-added time – Monitor packaging processes to identify sources of delays between cycles. Reduce machine set-up times, change-over times between products and non-productive downtime.

Implement lean manufacturing principles – Apply techniques like single-piece flow, visual management and just-in-time production to eliminate waste and non-value-added activities from packaging lines.

Optimize machine settings – Ensure packaging machines are running at their optimal speeds and settings. calibrate and maintain equipment regularly to maximize efficiency.

Measure key performance indicators – Track metrics like packages per hour, changeover times, downtime percentages and waste levels to identify areas for improvement. Set goals and implement changes based on data.

FAQ

Q: What types of cheese packaging machines are common?

A: Common types include vacuum packaging, flow wrapping, and form-fill-seal machines, suitable for various packaging needs.

Q: How do these machines enhance packaging efficiency?

A: They automate the process, increase speed, maintain consistent quality, and reduce manual labor, thereby enhancing efficiency.

Q: Can they handle different cheeses and packaging sizes?

A: Yes, most machines are adaptable to different cheese types and sizes with adjustable settings.

Q: What are important factors when selecting a machine?

A: Key factors include machine capacity, compatibility with different cheeses, speed, durability, and ease of maintenance.

Q: How do they ensure product quality and safety?

A: These machines use precise packaging techniques and food-grade materials to maintain hygiene and keep cheese fresh.

Conclusion

Cheese packaging machines are essential for cheese manufacturers to efficiently and consistently package cheeses in ways that maintain quality and freshness. By understanding how these machines work, their benefits, and maintenance requirements, cheese manufacturers can make informed decisions when selecting, operating

Lintyco is a pioneer and leader in automated Cheese Packing Machines and end-to-end packaging systems. Lintyco’s innovative packaging solutions for food, pharma, and other applications are complemented by advanced solutions for secondary packaging, wrapping & cartoning, bulk packaging, and more. Whether you are looking for a new machine or a complete line, or if you just want to upgrade your current packaging machine, talk to Lintyco. As experts of the industry with over three decades of proven expertise, Lintyco will provide the optimal solution backed by excellent consultancy and support.