Industrial labeling machines represent a critical component of modern manufacturing and packaging operations, providing automated solutions for applying labels to products across diverse industries. These sophisticated systems have evolved from simple manual dispensers to highly automated, computer-controlled machines capable of handling complex labeling requirements at high speeds and with exceptional precision.

The technology encompasses various application methods including wrap-around, print-and-apply, sleeve labeling, and specialty techniques for irregular containers, serving industries from pharmaceuticals and food production to electronics and cosmetics. Modern industrial labelers offer significant advantages including increased efficiency, improved quality consistency, reduced labor costs, and enhanced product traceability, while supporting compliance with regulatory requirements and brand identity standards.

Overview and Definition of Industrial Labeling Machines

Industrial labeling machines are specialized automated equipment designed to dispense, apply, or print-and-apply labels to various products, containers, or packages within manufacturing and packaging environments. These machines represent a fundamental shift from manual labeling processes to automated systems that can handle large production volumes with consistent quality and speed. The core function of an industrial labeler involves the systematic application of labels to products as they move through production lines, ensuring accurate placement, proper adhesion, and consistent appearance.

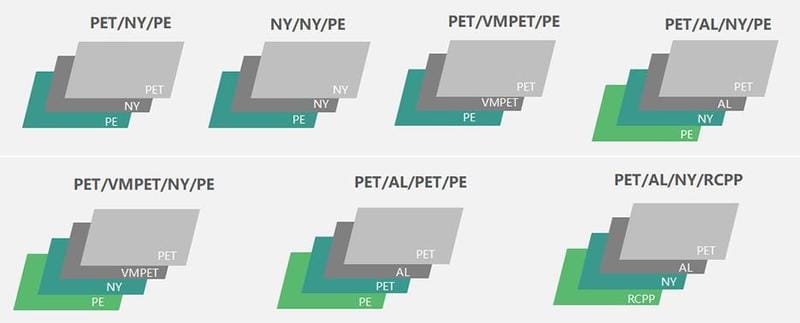

The definition of industrial labeling machines encompasses a broad range of equipment types, from semi-automatic units requiring operator intervention to fully automatic systems integrated into complete production lines. These machines are engineered to work with diverse materials including glass, plastic (PE, PET, HDPE), metal containers, and various label types such as paper, foil, transparent, and metallized labels. The versatility of modern industrial labelers allows manufacturers to adapt quickly to different product formats and labeling requirements without extensive equipment changes.

Modern industrial labeling systems are characterized by their modular design approach, enabling customization for specific applications while maintaining cost-effectiveness. This modularity allows manufacturers to build labeling solutions that precisely match their production requirements, from basic single-label applications to complex multi-panel labeling systems. The evolution of these machines reflects the increasing demands of modern manufacturing for flexibility, efficiency, and quality consistency in product identification and branding.

Operating Principles and Technology

The fundamental operating principle of industrial labeling machines involves a sophisticated sequence of mechanical and electronic processes designed to achieve precise label placement. The labeling process begins with products being fed onto a conveyor system at constant speed, where mechanical positioning devices separate items by fixed distances and guide them through the labeling zone. The mechanical system typically includes drive wheels, labeling wheels, and label reels that work in coordinated motion to ensure accurate label application.

Label application technology varies significantly depending on the specific machine type and application requirements. The most common methods include roll-on application, where labels are pressed onto products using pressure rollers, blow-on application utilizing compressed air to position labels, and tamp-on application where mechanical pads press labels firmly onto surfaces. Advanced systems incorporate registration marks on label tape to ensure precise positioning, with sensors reading these marks and making real-time adjustments to correct any mispositioning during the application process.

Print-and-apply systems represent a more sophisticated technological approach, combining label printing and application in a single automated process. These systems can print variable data such as barcodes, expiration dates, lot numbers, and other product-specific information directly onto labels immediately before application. The integration of thermal transfer or direct thermal printing technology allows for on-demand customization while maintaining high-speed production capabilities, making these systems particularly valuable for applications requiring frequently changing product information.

The control systems of modern industrial labelers utilize programmable logic controllers (PLC) and human-machine interfaces (HMI) to manage complex labeling parameters. These systems can store multiple recipes for different product formats, automatically adjusting label positioning, application pressure, and timing parameters based on the specific product being labeled. Advanced sensors monitor label presence, product positioning, and application quality, providing real-time feedback to ensure consistent results throughout production runs.

Types and Classifications of Industrial Labeling Machines

Industrial labeling machines can be classified into several distinct categories based on their automation level, application method, and intended use. Semi-automatic labeling machines represent the entry-level option for many manufacturers, requiring manual product placement while automating the label application process. These machines are particularly well-suited for small to medium production volumes and applications requiring frequent format changes, as they offer flexibility and cost-effectiveness for businesses with diverse product lines.

Automatic labeling machines provide fully automated operation designed for high-volume production environments where continuous operation and minimal operator intervention are essential. These systems can be integrated into complete packaging lines or operate as standalone units, offering production speeds that can reach up to 30,000 labels per hour depending on the specific application and machine configuration. Automatic systems typically feature advanced product handling mechanisms, precise positioning controls, and quality monitoring systems to ensure consistent results throughout extended production runs.

Application method classification reveals several specialized machine types designed for specific labeling challenges. Wrap-around labeling machines apply labels by rolling them onto cylindrical or round containers, providing maximum printable surface area and excellent adhesion characteristics. These machines are particularly popular in the beverage industry and for products requiring 360-degree labeling coverage. Self-adhesive labeling machines represent the most common type, using pressure-sensitive labels that require no additional adhesives or heating.

Specialized labeling technologies include sleeve labeling machines that apply shrink-sleeve labels for products requiring tamper-evident packaging or unique container shapes. Hot glue and cold glue labeling machines use liquid adhesives for applications requiring exceptional durability or for use in challenging environmental conditions. Print-and-apply systems combine printing and labeling functions, enabling variable data printing for applications requiring individual product identification or compliance labeling.

Applications Across Industries

The food and beverage industry represents one of the largest markets for industrial labeling machines, encompassing applications from bottle labeling in beverage production to complex multi-panel labeling for food containers. Bottle labeling applications require machines capable of handling various container materials including glass and plastic, with wrap-around labelers being particularly popular for cylindrical containers. Food packaging applications often require specialized features such as FDA-compliant stainless steel construction and food-grade belting systems to meet regulatory requirements.

Pharmaceutical and healthcare industries demand labeling solutions that ensure regulatory compliance, product traceability, and patient safety. These applications typically require high-precision label placement, integration with track-and-trace systems, and the ability to handle small containers such as vials and single-dose packages. The pharmaceutical sector often requires specialized labeling machines capable of applying multiple labels with different information types, including patient information, regulatory labels, and anti-counterfeiting features.

Chemical and industrial product labeling presents unique challenges requiring robust machines capable of handling hazardous material labeling and compliance with safety regulations. These applications often involve labeling containers that may be exposed to harsh environmental conditions, requiring specialized adhesives and label materials. Electronics and technology product labeling requires precision application of small labels containing detailed technical information, barcodes, and regulatory compliance markings.

Cosmetics and personal care products represent a growing application area where aesthetic considerations are paramount, requiring labeling machines capable of applying decorative labels with perfect alignment and finish quality. The automotive industry utilizes industrial labeling machines for parts identification, quality control labeling, and compliance marking throughout the manufacturing process. Logistics and shipping applications rely heavily on print-and-apply systems for address labels, shipping labels, and tracking information.

Benefits and Advantages of Industrial Labeling Automation

The implementation of industrial labeling machines provides significant efficiency improvements over manual labeling processes, with automation reducing production time and enabling consistent output rates. Modern labeling systems can operate continuously with minimal supervision, replacing the work of multiple operators while maintaining superior accuracy and consistency. The precision of automated labeling ensures uniform label placement, reducing waste and improving product appearance, which directly impacts brand image and customer perception.

Quality improvements represent another major advantage of industrial labeling automation, with machines providing consistent label placement accuracy that human operators cannot match. Automated systems eliminate variability in label positioning, pressure application, and overall appearance, ensuring that every product meets the same high standards. This consistency is particularly important for products requiring regulatory compliance or those sold in competitive retail environments where appearance quality influences purchasing decisions.

Cost reduction benefits extend beyond labor savings to include reduced material waste, improved production efficiency, and decreased rejection rates. Industrial labeling machines optimize label usage through precise application and reduce the need for rework or rejected products due to labeling errors. The ability to quickly change between different label formats and product types reduces setup time and increases overall equipment effectiveness, providing additional cost benefits through improved production flexibility.

Product traceability and inventory management capabilities are enhanced through the integration of barcode printing and application systems, enabling comprehensive tracking throughout the supply chain. Modern labeling systems can integrate with enterprise resource planning (ERP) systems and quality management systems, providing real-time production data and ensuring compliance with tracking requirements. This integration supports regulatory compliance, quality control processes, and efficient inventory management across complex supply chains.

Technical Specifications and Features

Modern industrial labeling machines incorporate sophisticated control systems featuring programmable logic controllers (PLC) with intuitive human-machine interfaces (HMI) for simplified operation and parameter adjustment. These control systems typically support multiple program storage capabilities, allowing operators to quickly switch between different product configurations without extensive setup time. Touch-panel controls provide user-friendly access to all machine settings, with many systems offering remote monitoring capabilities for enhanced production oversight.

Label handling capabilities vary significantly among different machine types, with standard systems accommodating label widths ranging from 20mm to 220mm and various label lengths depending on application requirements. Advanced machines feature automatic label detection systems that can work with transparent labels and provide end-of-roll warnings to prevent production interruptions. Quick-change systems enable rapid format changeovers, with some machines offering tool-free adjustments for common parameter changes.

Production speed specifications depend on machine type and application complexity, with high-speed systems capable of applying labels at rates exceeding 2,400 containers per hour for carton labeling applications. Wrap-around labeling systems can achieve speeds appropriate for beverage production lines, while print-and-apply systems typically operate at speeds up to 270 labels per minute depending on label size and complexity. These speed capabilities enable integration into high-volume production environments while maintaining labeling accuracy.

Construction standards for industrial labeling machines emphasize durability and reliability for continuous operation environments. Many machines feature stainless steel construction (304 or 316 grade) for food-grade applications, with IP65 protection ratings for use in wash-down environments. Modular design approaches enable easy maintenance access and component replacement, while safety features including emergency stops and protective enclosures ensure compliance with industrial safety standards.

Selection Criteria and Considerations

Product characteristics represent the primary consideration when selecting industrial labeling machines, including container material, shape, size variations, and surface texture requirements. Round containers typically require wrap-around labeling systems, while flat surfaces may utilize front-and-back labeling or single-side application. Container materials influence adhesive selection and application method, with glass, plastic, and metal containers each presenting unique labeling challenges that must be addressed through appropriate machine selection.

Production volume requirements directly impact the choice between semi-automatic and fully automatic systems, with high-volume operations benefiting from the continuous operation capabilities of automatic machines. Semi-automatic systems provide cost-effective solutions for smaller production runs or applications requiring frequent product changeovers, while automatic systems offer superior efficiency for continuous production environments. The anticipated growth in production volume should also be considered to ensure selected equipment can accommodate future expansion needs.

Integration requirements with existing production line equipment influence machine selection, particularly regarding conveyor compatibility, control system integration, and available floor space. Many modern labeling machines offer modular designs that facilitate integration with existing packaging equipment, checkweighers, and quality control systems. Communication protocols and data exchange capabilities are essential considerations for facilities utilizing integrated production management systems.

Label specifications including size, material, adhesive type, and printing requirements must align with machine capabilities. Print-and-apply systems are necessary for applications requiring variable data printing, while pre-printed label applications may utilize simpler applicator systems. The variety of label types and sizes required in production influences the need for quick-change capabilities and format flexibility in the selected equipment.

Conclusion

Industrial labeling machines have become indispensable components of modern manufacturing operations, providing automated solutions that enhance efficiency, quality, and compliance across diverse industries. The evolution from manual labeling processes to sophisticated automated systems reflects the increasing demands of contemporary manufacturing for precision, speed, and flexibility in product identification and branding. The comprehensive range of available technologies, from basic semi-automatic systems to advanced print-and-apply units, enables manufacturers to select solutions that precisely match their operational requirements and production volumes.

The benefits of industrial labeling automation extend far beyond simple labor cost reduction, encompassing quality improvements, enhanced traceability, reduced waste, and improved compliance capabilities that are essential for competitive manufacturing operations. The integration of advanced control systems, modular designs, and sophisticated application technologies ensures that modern labeling machines can adapt to changing production requirements while maintaining consistent performance standards. As manufacturing continues to evolve toward greater automation and customization, industrial labeling machines will play an increasingly critical role in enabling efficient, flexible, and quality-focused production operations.

Future developments in industrial labeling technology are likely to focus on enhanced integration capabilities, improved sustainability through reduced waste and energy consumption, and advanced monitoring systems that provide comprehensive production analytics. The selection of appropriate labeling equipment requires careful consideration of current production needs, future growth plans, and integration requirements to ensure optimal return on investment and long-term operational success.