As a packaging machine engineer for 20 years, today we will introduce the snack food packaging machine. . If you run a snack business or plan to start one, knowing snack packaging machines is imperative.

In this thorough guide, we will discuss a broad spectrum of questions relevant to snack packaging machines, from their functions and kinds to common troubleshooting tips. Whether you are a budding or seasoned snack maker, this guide will equip you with the understanding and know-how indispensable. Let us delve into the realm of snack packaging machines!

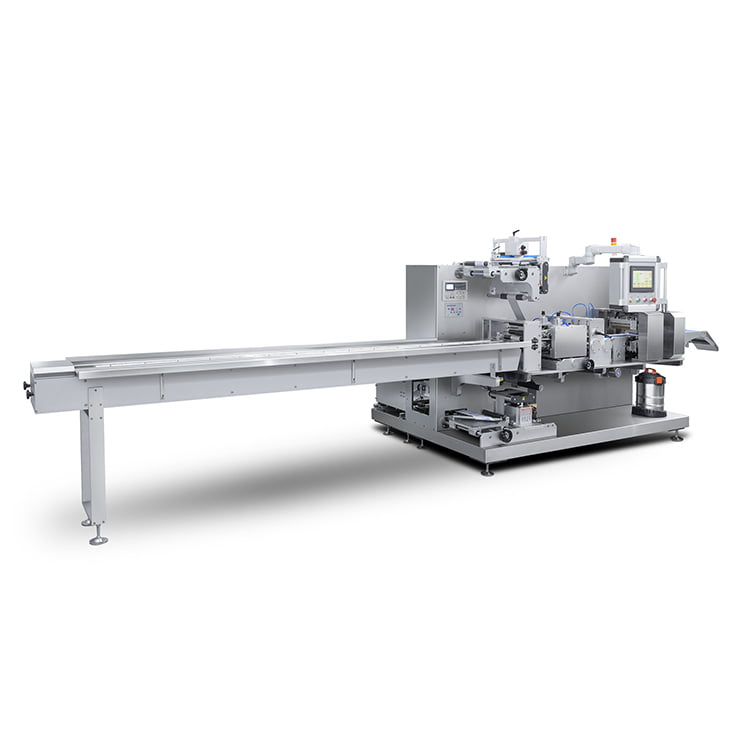

What is a snack packaging machine?

A snack packaging machine is a specific type of equipment used in the food packaging sector to mechanize the snack packing process. These machines perform various tasks, including filling, sealing, labelling, and occasionally even categorizing snacks into their final packaging like bags, pouches, or boxes. Snack packaging machines are vital in enhancing production effectiveness and guaranteeing consistent packaging quality.

What types of snack products can be packaged using snack packaging machines?

Snack packaging machines are adaptable and can wrap various kinds of snacks, like:

- Crisps: Potato crisps, tortilla crisps, pita crisps and other similar snack products.

- Biscuits: Packaged cookies, biscotti, wafer sticks and other bakery products.

- Nuts: Almonds, peanuts, cashews, pistachios and other nut varieties.

- Biscuits: Cracker biscuits, graham biscuits, cheese biscuits and more.

- Dried fruit: Raisins, dried apricots, dried cranberries and other dehydrated fruit snacks.

- Mixed snacks: Trail mixes, party mixes, granola mixes and other combined snack mixtures.

How does a snack packaging machine work?

Snack packaging machines are designed with sophisticated mechanisms and controls to streamline the packaging process. Here is a simplified overview of how a typical snack packaging machine operates:

- Filling and loading: Snacks are loaded into the machine’s hopper or conveyor system, which transfers them to the packaging area. The machine then measures and dispenses the desired amount of snacks into individual packaging units.

- Packaging material handling: The machine handles the packaging material, such as film rolls or preformed pouches, and positions them correctly to receive the snacks.

- Sealing: The packaging material is formed around the snacks, and the machine seals it securely to prevent air and moisture from entering. The sealing process can involve heat, pressure, or adhesives depending on the packaging material and design.

- Labelling and coding: If required, the machine can put labels or codes on the packaging for identification, expiry dates, or branding.

- Quality control: snack packaging machines use sensors and inspection systems to find problems like bad seals or foreign objects. This helps make sure only good packages are made.

- Finished product discharge: The packaged snacks are discharged from the machine, ready for storage, distribution or retail display

What are the different types of snack packaging machines?

There are various models of snack packaging machines available, customized to meet different packing needs. Some common types involve:

- Vertical form fill and seal(VFFS) machines: Ideal for wrapping snacks in pouches or bags, providing flexibility in bag sizes and styles.

- Horizontal form fill and seal(HFFS) machines: Suitable for wrapping snacks in flat or stand-up pouches, delivering excellent product visibility.

- Prepackaged pouch packing machines: These machines accurately weigh and distribute snacks into individual packages, ensuring uniform portion sizes.

- Tray sealing machines: Used for packaging snacks in trays or containers, offering tamper-proof seals and attractive presentation.

- Vacuum packaging machines: remove air from packaging to keep snacks fresh. They come in different types, from affordable to advanced systems with precise automation and high production output. They assist snack producers in cutting packaging costs while optimizing line efficiency, product protection and brand appeal.

How do I choose the right snack packaging machine for my business?

Choosing the proper snack packaging machine hinges on several elements, including your production volume, snack varieties, packing requirements, and budget. Consider the following when selecting a machine:

- Carefully study different producers and suppliers of snack packaging machines. Browse reputable companies with a proven track record of offering dependable and high-quality equipment. Read customer reviews and seek recommendations from industry professionals.

- Determine your precise packaging needs. Consider the types and sizes of snacks you want to wrap. Also, think about how quickly you want to pack them and how much automation you require. Having a clear understanding of your needs will assist you in making a decision. Knowing what you need will help you choose.

- Determine your budget range for the snack packaging machine. Consider the return on investment over the long term and factor in costs beyond the initial purchase price, like maintenance, spare parts, and training. Get Your Free Machine ROI Calculator.

- Make sure the snack packaging machine works with your current production line or other equipment. Check the size, power needs, and any extra connections needed for smooth integration

- Assess the manufacturer’s support and training. A good supplier should give thorough training to your workers and offer quick assistance for technical problems or breakdowns.

- Attend trade shows or exhibitions related to packaging machinery. This provides an opportunity to explore different models, compare features, and personally interact with manufacturers and industry experts.

- Request demonstrations of the snack packaging machines you are interested in. This allows you to observe the machine’s performance, assess its ease of use, and even request samples of packaged snacks for quality evaluation.

- Check the warranty and service agreements from the manufacturer. Understand what is covered, how long it lasts, and any extra services like maintenance or software updates.

Can snack packaging machines be integrated into existing production lines?

snack packaging machines can be integrated into existing production lines. Here are some points regarding snack packaging machine integration:

- Snack packaging machines are designed to be compatible with other machinery and can fit into existing production workflows. Snack Packaging Machine Manufacturers offer models of varying sizes and configurations to integrate easily.

- Most snack food packaging machines have standardized interfaces to connect with other equipment. For example, the machine’s infeed and outfeed systems can match conveyor belt widths and speeds.

- When choosing a snack packaging machine, think about size, power needs, air pressure, and if it works with your current system.

- Manufacturers can provide custom modifications to snack packaging machines as needed for specific integration requirements. For example, customized infeed, outfeed or control systems.

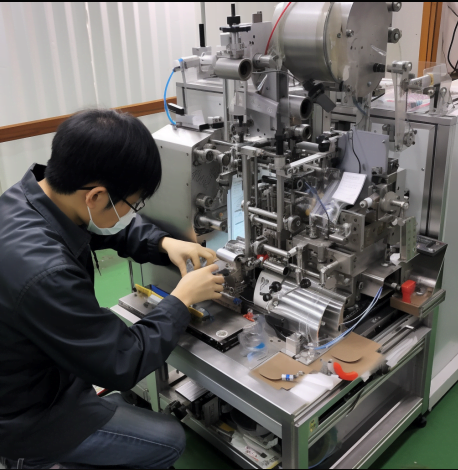

- Snack packaging machine integration often requires engineering support to accurately map out the workflow, identify potential bottlenecks, and optimize the layout. Professional installation is also recommended.

- Integrating snack packaging machines into an existing production line can help increase the overall efficiency of operations. Automation and synchronization of processes improve throughput and consistency.

- Integration may require additional equipment, such as conveyors and buffers. This equipment is necessary to ensure that products move smoothly through the packaging process. It also helps to facilitate the transition onto palletizing or shipping.

How do I maintain a snack packaging machine?

Proper maintenance is vital for the optimal performance and longevity of a snack packaging machine. Here are some maintenance tips:

- Regular cleaning: Clean the machine consistently, removing any food waste, dust or residue that may affect its performance.

- Lubrication: Follow the manufacturer’s guidelines and lubricate moving parts to minimize friction and ensure smooth running.

- Inspections: Conduct routine inspections to detect any worn or damaged parts that necessitate replacement.

- Operator training: Train your operators on proper machine operation, maintenance process and safety protocols.

- Scheduled servicing: Adhere to the manufacturer’s recommended maintenance schedule and seek professional servicing when necessary.

What are common issues and troubleshooting tips for snack packaging machines?

Some common issues with snack packaging machines include misfeeds, sealing failures, product jams, or incorrect portioning. Here are some troubleshooting tips:

- Check the feeding system: Ensure the feeding mechanism is properly adjusted and free from obstructions.

- Review the sealing process: Verify that the sealing temperature, pressure, and timing settings are appropriate for the packaging material and snack type.

- Inspect mechanical components: Look for loose belts, worn-out parts, or foreign objects that may hinder the machine’s performance.

If issues persist, consult the machine’s manual or contact the manufacturer for further assistance.

How to Improve Snack Food Packaging Efficiency and Productivity?

- Invest in the right packaging machines. High-speed, automated snack packaging machines can dramatically improve efficiency and throughput. Consider machines with features like auto bagging, sealing, labelling and portion control.

- Implement automation and integration. Fully automating packaging processes and integrating machines into an automated production line helps minimize manual labour and delays. This leads to higher output and less waste.

- Optimize packaging line layout. A well-designed packaging line layout with minimal bottlenecks and overlapping processes can significantly boost productivity. Place machines strategically to reduce the travel distance of products and operators.

- Improve changeover speed. Faster changeovers between snack varieties or package sizes mean more production time and higher output. Look for packaging machines designed for quick and tool-less changeovers.

- Monitor machine performance. Use sensors, data loggers and other monitoring tools to detect issues early on and maximize the uptime of packaging machines. Schedule timely maintenance to avoid unexpected breakdowns.

- Reduce product giveaways. Accurate portion control and weight monitoring systems can help minimize excess product waste during packaging. This conserves ingredients and boosts productivity.

- Train operators properly. Train your packaging line operators to operate machines efficiently and identify issues promptly. Provide refresher courses periodically to reinforce best practices.

- Implement lean manufacturing techniques. Following principles like just-in-time production, continuous improvement, visual management and mistake-proofing can optimize your entire snack packaging process.

- Use quality packaging materials. Selecting durable, trouble-free packaging materials like laminated pouches and bags can increase machine uptime and throughput.

- Track and analyze key metrics. Monitor metrics like OEE (Overall Equipment Efficiency), packaging speed, changeover times and product waste. Take corrective action based on data insights.

Future Speculation Of Snack Food Packaging Machinery Technology

Explore the latest technological advancements, including robotics, automation, smart control systems, and eco-friendly packaging options in snack food packaging machinery.

[Idea 1] Create a machine that can sort, pack, and seal snacks for various customers.

[Idea 2] Create a reusable snack packaging container that can reduce packaging waste and be friendly to the environment.

[Idea 3] Create a smart robot that can use AI and machine vision to identify and pack snacks in a fast manner.

[Idea 4] Design a snack packaging machine that can automatically adjust packaging methods and materials according to consumers’ tastes and preferences.

[Idea 5] Make a DIY kit for a snack packaging machine so people can build and personalize their own machine.

[Idea 6] Use 3D printing to make the parts of the snack packaging machine, which cuts costs and boosts production speed.

[Idea 7] Create an app to control and monitor snack packaging machines from a distance.

[Idea 8] Use blockchain to create a clear platform for making and delivering snack packaging machines, to increase trust in them.

[Idea 9] Create a machine that puts QR codes or RFID tags on snack packages. This helps people easily buy snacks by scanning codes or swiping cards.

[Idea 10] Create a machine artwork that can be decorated with parts to become a unique exhibit for snack packaging

FAQ

Q: What Types of Snacks Can Be Packaged Using These Machines?

A: The machines are capable of packaging various snacks including crisps, biscuits, nuts, dried fruits, and mixed snacks.

Q: How Does a Snack Packaging Machine Work?

A: These machines automate processes like filling, handling packaging materials, sealing, and quality control.

Q: What are the Different Types of Snack Packaging Machines?

A: The guide details various types, including vertical and horizontal form fill and seal machines, and premade pouch packing machines.

Q: How to Choose the Right Snack Packaging Machine?

A: Key factors include production volume, snack types, specific packaging requirements, and budget considerations.

Q: Can Snack Packaging Machines Be Integrated into Existing Production Lines?

A: Yes, they can be integrated with possible custom modifications for seamless operation.

Conclusion

Snack packaging machines are indispensable tools for snack manufacturers looking to boost productivity,maintain packaging quality and meet market demands. By understanding how these machines function,their significance and maintenance needs, you can make informed decisions when selecting, running and maintaining snack packaging machines. Investing in a dependable and effective snack packaging machine can distinctly contribute to the success of your snack business by ensuring uniform packaging quality and customer satisfaction.

Lintyco is a pioneer and leader in automated Snack Filling Machines and end-to-end packaging systems. Lintyco’s innovative packaging solutions for food, pharma, and other applications are complemented by advanced solutions for secondary packaging, wrapping & cartoning, bulk packaging, and more. Whether you are looking for a new machine or a complete line, or if you just want to upgrade your current packaging machine, talk to Lintyco. As experts of the industry with over three decades of proven expertise, Lintyco will provide the optimal solution backed by excellent consultancy and support.