Introduction

Are you looking for success? Packaging problems shouldn’t ruin your prosperity recipe! Let’s dive fork-first into the delicious world of food packaging machines for small businesses. Let’s fill your mind with knowledge and humor.

Type of Food Packaging

In the realm of small-scale food ventures, the significance of adept packaging is paramount for maintaining product integrity, prolonging shelf life, and boosting brand image. Thankfully, the market offers a diverse array of food packaging machines specifically engineered to cater to the nuanced demands of small operations. This discussion will shed light on several types of food packaging machinery that are particularly beneficial for small enterprises, aiming to refine their packaging processes and uphold industry benchmarks.

Chamber Vacuum Sealers

For small food entities eager to enhance the longevity of their offerings, vacuum sealers are crucial. These devices remove air from the packaging, generating a vacuum-sealed milieu that conserves the freshness and minimizes spoilage risks. Perfect for perishables such as meats, cheeses, and ready-made dishes, vacuum sealers are instrumental in elevating product quality and customer contentment.

Tray Sealers

Tailored for small businesses, tray sealers are adept at sealing food items in trays or bowls. They are extensively utilized for packaging produce, snacks, and prepared foods. Tray sealers not only secure the product but also minimize contamination risks, thereby improving the aesthetic and shelf life of the packaged items.

Flow Wrappers

These machines are versatile in wrapping individual products using a continuous film roll, making them ideal for small businesses producing bakery items, candies, and snacks. Flow wrappers seal products tightly, accommodating various sizes and shapes, and ensure the packaging looks professional and appealing.

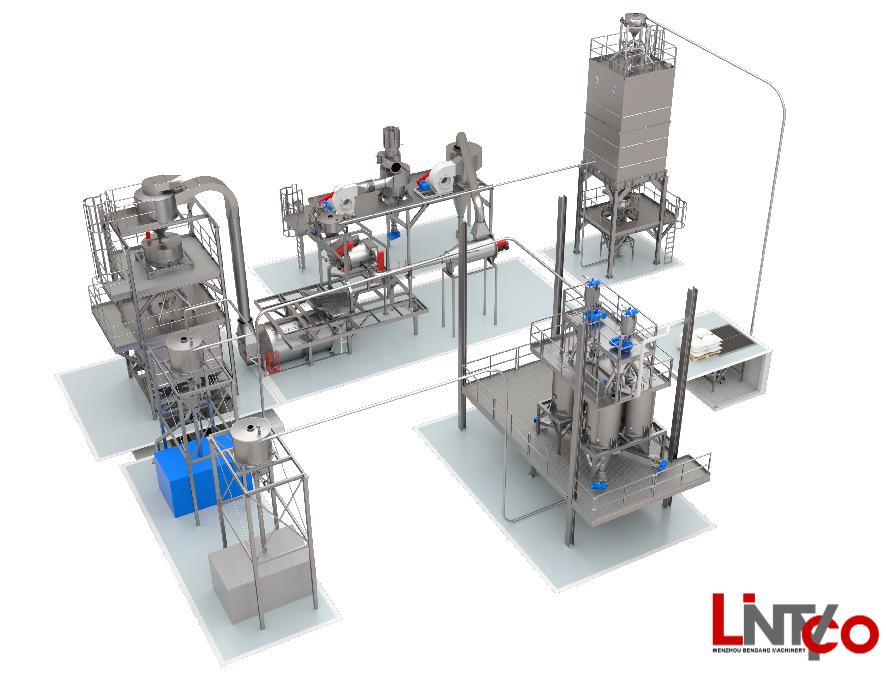

Form-Fill-Seal Machines

Crucial for small-scale food operations aiming for packaging automation, these machines can process a broad spectrum of food items, from liquids to solids. Form-fill-seal machines allow businesses to create, fill, and seal packages efficiently, suitable for items like sauces, grains, and beverages.

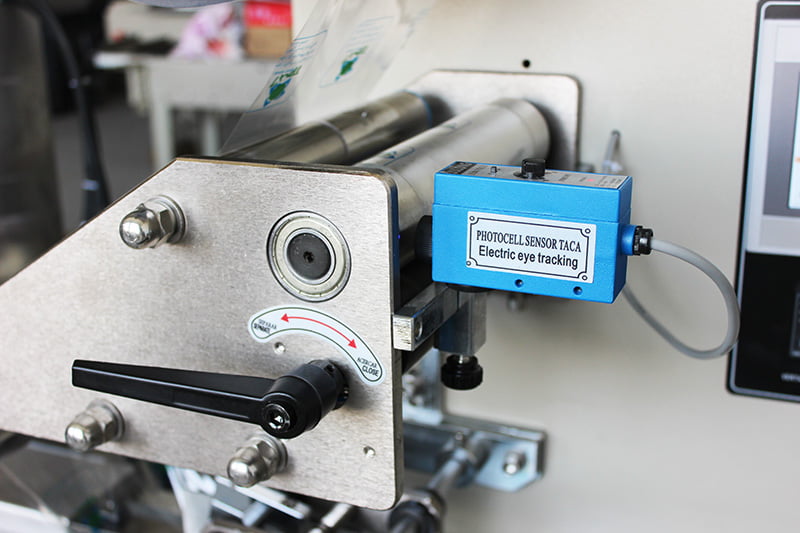

Labeling Machines

For small enterprises, labeling machines facilitate the precise application of product details, brand information, and regulatory compliance labels. These machines make the labeling process consistent and professional, enabling small food businesses to adhere to industry standards and enhance brand visibility.

Shrink Wrappers

Utilizing heat to snugly fit plastic film around products, shrink wrappers are perfect for small businesses packaging bottled drinks, canned items, or product bundles. This method not only secures the product during transportation but also improves the package’s aesthetic appeal, making it ready for the market.

Bag Sealers

These machines offer a feasible option for sealing plastic bags or pouches and are available in various sizes, including handheld options for smaller operations. Ideal for packaging a range of items from spices to frozen foods, bag sealers help small businesses maintain freshness, prevent contamination, and ensure secure packaging.

Induction Sealers

An indispensable tool for ensuring product safety and longevity, induction sealers are designed to seal the tops of bottles and jars with a foil seal. This technology is especially crucial for small businesses that bottle liquids such as sauces, oils, and beverages. Induction sealers provide a hermetic seal that prevents leaks, ensures product integrity, and extends shelf life. Moreover, the seal acts as a tamper-evidence mechanism, giving consumers confidence in the safety and quality of the product.

Capping Machines

Small businesses that require efficient, reliable sealing of their bottled products will find great value in capping machines. These machines are tailored to fit caps of various sizes and types onto bottles, ensuring a tight seal that maintains product quality and freshness. Whether it’s for carbonated drinks, nutritional supplements, or any liquid product, capping machines enhance operational efficiency by automating the capping process, thus reducing labor costs and increasing production throughput.

How To Choose The Right Packaging Machines For Your Business

Selecting the ideal packaging machine is a decision that can significantly impact a business’s operations. The right machine not only boosts productivity and reduces costs but also diminishes the chances of product rejection. In today’s global market, with the advent of new technologies, the role of packaging machines becomes even more crucial, enabling businesses to stay competitive and venture into new markets.

Investing in machinery for a production line is a significant commitment in both time and financial resources. Businesses must carefully assess their needs to avoid the pitfalls of choosing a machine that may not align with their current or future production needs, potentially leading to financial losses.

Enhancing Productivity

The potential to increase productivity is a primary consideration. However, the capability of your existing systems and workforce to handle increased output must also be evaluated. While a large, high-capacity machine may seem beneficial, it could lead to inefficiencies if other parts of the production process cannot keep pace. Conversely, a slower machine might hinder the ability to scale up production when needed.

Choosing Flexible Packaging Machines Selecting machines that offer upgrade options, such as transitioning from semi-automatic to fully automatic or adding additional components, can provide long-term benefits. Compatibility with existing systems, like cappers and labeling machines, is also essential. Experienced manufacturers can offer valuable insights into choosing machines that match your business’s growth projections.

Type of Filling Mechanism

Different products necessitate distinct types of filling mechanisms. Liquid products, for instance, may require different machines depending on their viscosity. Carbonated beverages need specific filling heads to mitigate foaming, while bulk items might be better suited to pump filling. A thorough understanding of your product’s characteristics allows manufacturers to recommend the most appropriate machinery.

Volume and Accuracy

The size of the containers and the required filling accuracy are also crucial. Machines vary in their capacity and precision, which can affect both wastage and compliance with regulatory standards. Opting for machinery that guarantees high accuracy can lead to significant cost savings and maintain customer trust.

Durability and Support

Longevity and reliability are key when making a substantial investment in packaging machinery. Opting for higher quality machines might come at a higher initial cost but can save on repair costs and downtime in the long run. Access to prompt and effective customer support, especially from local suppliers, is also a significant consideration.

Adaptability and Customization For businesses with a diverse product range, the adaptability of packaging machinery is paramount. Machines must be versatile enough to handle various container sizes and shapes, as well as different cap types and configurations. The ability to modify and upgrade your machinery to increase productivity or accommodate new packaging styles is an advantage.

Consistency Across the Board Ensuring consistent quality in packaging is crucial for maintaining productivity gains. Machines should consistently deliver well-sealed containers, accurately placed labels, and uniform product filling to avoid negating efficiency improvements.

Manual, Semi-Automatic, or Automatic Operation The scale of operation may dictate whether manual, semi-automatic, or fully automatic machines are most appropriate. Manual options may be sufficient for smaller operations, while fully automatic machines cater to higher production volumes. Flexibility to upgrade or rent additional components can provide scalability as needed.

Hygiene Standards and Maintenance Particularly relevant in the food and pharmaceutical sectors, machines must meet high hygiene standards, be constructed from cleanable materials, and allow for easy maintenance to minimize downtime.

Consideration of Labor and Workflow The introduction of packaging machines can significantly reduce labor costs and reallocate workforce resources. Machines should be user-friendly, with minimal training requirements, and suppliers should offer comprehensive support and training.

Space and Workflow Integration Planning for the physical integration of new machinery into your production environment is crucial, taking into account space limitations and the need for additional equipment or staff training.

Purchase or Rental Options Renting equipment may be a viable option for businesses looking to test new technology or manage seasonal variations without a long-term commitment.

Understanding Your Business Needs Armed with these considerations, businesses are better equipped to make informed decisions regarding packaging machinery investments. Clear identification of needs facilitates effective communication with suppliers, ensuring tailored solutions that enhance productivity, accuracy, and worker support, guiding you towards the optimal system for your operations.

Conclusion

Small businesses are fun, but they can get messy quickly – like juggling flaming meatballs on a unicycle. The food packaging machine plays an important role in packaging, and it saves the day by playing the role of the superhero. Without the machine, small businesses would be overwhelmed and unable to keep up with the demand. The machine not only reduces the manual labor, but also increases efficiency and productivity. It’s an indispensable tool for any business. Get Your Free Food Packging Solution for Lintyco expert Here

Frequently Asked Questions

What are the benefits of investing in a food packaging machine for a small business?

When a small business invests in a food packaging machine, it can improve efficiency, reduce waste, and increase quality, positioning it for growth and success.

When choosing a food packaging machine for a small business, what factors should be considered?

Key factors include the specific packaging needs of the business, budget constraints, space availability, and the machine’s flexibility to adapt to future growth.

How can food packaging machines help a small business become more eco-friendly?

It is possible for small businesses to reduce their environmental impact and appeal to eco-conscious consumers by choosing machines that support sustainable packaging practices and materials.

What impact does a food packaging machine have on the supply chain of a small business?

Packing machines can streamline manufacturing processes, resulting in better logistics, shorter lead times, and stronger relationships with suppliers.