Introduction of Continental Rollo Mixer

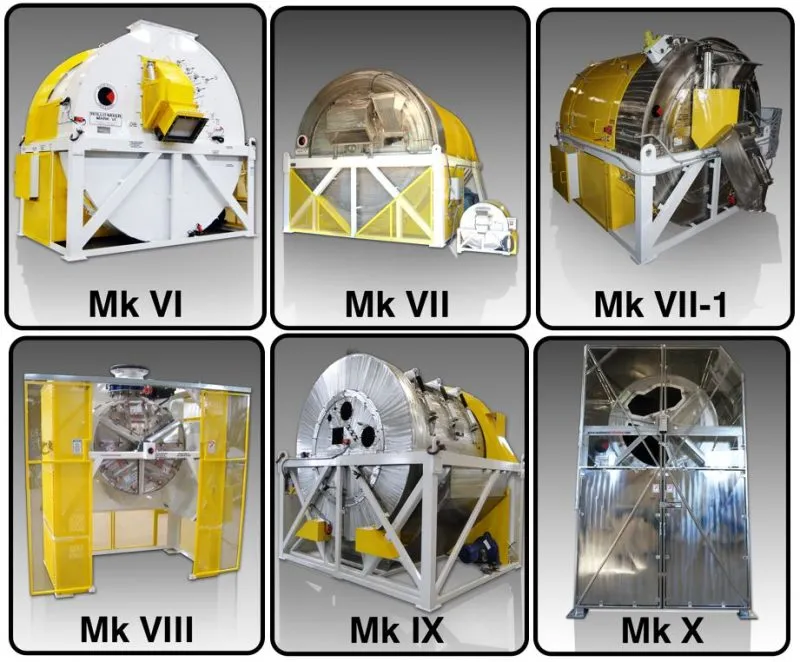

In 1960, D. Coyne Callaghan of Wisconsin developed the first Rollo-Mixer® drum mixer to mix dairy feed with liquid molasses. With continuous upgrades and iterations, six rotary drum mixer/sprayers have now been developed. Continuous improvement, a commitment to excellence and direct expertise enable customers to maintain the highest quality performance in the field.

The first Rollo-Mixer ® batch mixer was invented in 1960 to mix dairy feed with viscous molasses. Today, our customers in the feed industry produce all types of feed products, including: poultry feed, pig feed, beef feed and calf feed, as well as speciality racehorse feed destined for racecourses around the world. The gentle Rollo-Mixer ® has been one of the best industrial animal feed mixers in the world for many years. It excels at uniformly mixing friable ingredients such as rolled oats, corn flakes, steamed grains and pellets. For spraying animal feed, use the Liquid Mixer attachment to evenly coat a high percentage of viscous liquids such as molasses and fats.

Molasses Mixer Work Process

The Continental Rollo Mixer® has been producing animal feeds and calf feeds for over 60 years with the highest quality results. Textured feeds are transferred through a molasses mixer to receive different concentrations of molasses. Watch how multiple ingredients are loaded, gently mixed, coated with liquid molasses and unloaded directly onto a truck.

This Rollo Mixer® mixes 4,000 to 20,000 lbs. of feed per batch while evenly adding liquid molasses. The product is completely discharged and the molasses is evenly distributed and consistent from batch to batch.

Rollo-Mixer is proven to produce the highest quality animal feeds in the industry. Heifer calves, dairy cows, pigs and thoroughbred racehorses love the feed Rollo-Mixer has been producing for these animals since 1960.

Advanced Feed Packaging Machine from Lintyco

Feed packaging generally comes in a variety of options, bags, jars or boxes. Packaging determines the shelf life as well as the aesthetics of the product. A good design can lead to incremental sales, even if you are a startup.

Lintyco is a pioneer and leader in automated feed Packaging Machines and end-to-end packaging systems. Lintyco’s innovative packaging solutions for food, pharma, and other applications are complemented by advanced solutions for secondary packaging, wrapping & cartoning, bulk packaging, and more. Whether you are looking for a new machine or a complete line, or if you just want to upgrade your current packaging machine, talk to Lintyco. As experts of the industry with over three decades of proven expertise, Lintyco will provide the optimal solution backed by excellent consultancy and support.