Introduction: Why Coffee Pouches Are Taking Over

Hey there, coffee enthusiasts and packaging wizards! Ever wondered how that aromatic coffee makes its way into those neat little pouches that fit so snugly in your kitchen cabinet?

Well, the hero behind the scenes is none other than the coffee pouch machine. These ingenious devices are all about transforming bulk coffee into your daily doses of bliss, ready to brew.

This coffee pouch machine FAQ guide can explain to you the construction and features of different coffee pouch machine, as well as other frequently asked questions. Hope you will keep reading!

The Rise of Coffee Pouch Packaging

A coffee pouch machine is a coffee machine that uses pouches automatically to fill and pack coffee. The coffee includes coffee beans, coffee powders, and coffee granules. It has become an important part of the coffee packaging industry.

As well as providing coffee in bag packaging, the coffee pouch machine can also provide you with multi-functional packaging solutions. The coffee pouch machine can provide you with a wide range of packaging solutions, from food to personal care, pharmaceuticals, etc.

Industrial coffee pouch machine is not just a piece of equipment; it’s the last step in a coffee bean’s journey before it reaches your kitchen. Whether it’s a sleek, stand-up pouch or a simple, flat sachet, these machines make it happen. They come in various shapes and sizes, catering to different needs – from small, manual operations to large, fully automated systems.

Benefits of Using Coffee Packaging Bags

In your opinion, what are some of the benefits you would like from your coffee pouch filling machine if you are a coffee producer?

Benefits Of Using The Coffee Pouch Machine:

Reduction of Packaging Waste

Prior to employing a coffee pouch machine, the manual tasks of weighing, packing, sealing, etc., are prone to uncertainties, leading to material wastage. Through the automated processes of weighing, filling, packaging, and sealing facilitated by the coffee pouch machine, precise control over each step is achieved, minimizing waste significantly.

Preservation of Coffee Quality and Freshness

Each type of coffee possesses unique characteristics and flavors. To uphold the distinct freshness and flavor profiles of coffee, some packaging involves flushing with nitrogen. Utilizing a coffee pouch machine ensures effective airtight sealing, preventing moisture infiltration and preserving the quality of the coffee.

Enhanced Packaging Efficiency

Employing a fully automatic coffee pouch machine eliminates the need for manual intervention throughout the packaging process, except for initial setup, supervision, and later maintenance. This streamlined approach significantly boosts efficiency, translating into greater economic benefits for businesses.

Increased Versatility

Beyond basic functions such as weighing, filling, packaging, and sealing, modern coffee pouch machines offer additional features like counting, printing, error reporting, automatic maintenance, and cleaning. This versatility adds convenience to operations, enhancing overall productivity and ease of use.

Cost Savings through Bulk Purchases

Another significant benefit of utilizing a coffee pouch machine is the ability to purchase coffee in bulk quantities. Bulk purchases often come with discounted rates, enabling businesses to save on procurement costs while ensuring a steady supply of coffee for packaging. This cost-effective approach contributes to overall financial efficiency and sustainability.

Exploring Coffee Pouch Machines

Imagine the journey of a coffee bean, freshly roasted and bursting with flavors, as it makes its way into a pouch. It’s a delicate dance of technology and precision. First, the machine measures the correct amount of coffee. Then, it gently places it into the pouch, seals it to lock in freshness, and finally, the pouch is ready to be dispatched. This process not only preserves the coffee’s quality but also ensures consistency across batches.

How Do Coffee Pouch Machines Work?

The Filling Process

Imagine your coffee beans or grounds taking a dive into their new home. That’s what happens here – a perfectly measured belly flop.

Sealing and Cutting

With precision, the machine then seals the deal, quite literally, ensuring your coffee is snug and secure.

Quality Checks

Because no one wants a pouch of disappointment, quality checks are the machine’s way of giving each pouch a thumbs up.

Types of Coffee Pouch Machines

Automatic

For the high rollers in coffee production, automatic machines are the Ferraris of the packaging world – fast, efficient, and with a touch of elegance.

Semi-Automatic

A tad more hands-on, these machines strike a balance between automation and human touch, perfect for medium-sized operations.

Manual

Old school but reliable, manual machines are for those who like to feel every pouch’s pulse as it’s born.

If you want to know the differences and details between various machines, you can refer to our website:

VFFS Coffee Pouch Machines

Vertical form fill seal coffee pouch machines are known as VFFS coffee pouch machines. A VFFS coffee pouch machine is usually used to package free-flowing products such as cereals, powders, and liquids because of its vertical design and top-to-bottom coffee filling process.

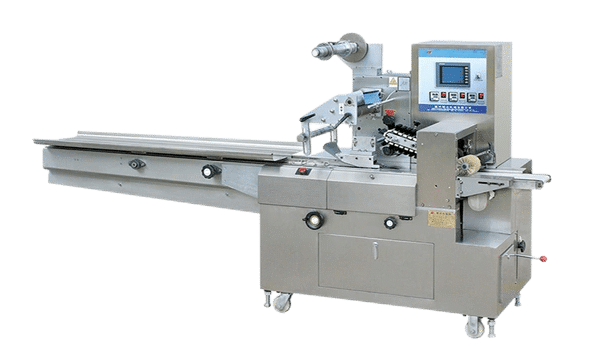

HFFS Coffee Pouch Machines

As the name implies, HFFS coffee pouch machines are horizontal form fill seal coffee pouch machines that can wrap coffees horizontally. As a result of its horizontal packaging design, HFFS coffee pouch machines can handle a variety of irregular shapes or larger products more effectively. They are also able to handle more efficient bag-making directions and product handling.

Doypack Coffee Pouch Machines

With the doypack coffee pouch machine, the pouch stands up, the bag forms, the material is filled, the pouch is sealed, and a date is printed automatically. With a photoelectric sensor tracking system and servo motor puller, all of these machines ensure a precise bag width and film positioning.

Selecting the Right Coffee Pouch Machine for Your Business

Finding the perfect coffee pouch machine for your business is akin to choosing a business partner. It’s a decision that requires careful consideration and understanding of your needs.

Key Factors to Consider

When selecting a coffee pouch machine, consider your production volume, the types of pouches you wish to use (such as stand-up, flat, or side gusset), and the specific features you need, like nitrogen flushing for freshness. The machine’s compatibility with your existing production line and its footprint are also crucial to ensure a smooth integration.

Coffee Powder Or Coffee Beans

If you are filling powder products, some machines only work with powder, and some machines work with both powder and granules. Consider clearly whether you need a powder product or a granular product according to how you are positioning your product.

Space

It is also important to consider the size and footprint of the machine. The footprint of horizontally designed machines is smaller than that of vertical machines. Multifunctional machines that are designed to be large are occupied by a large space. The efficiency of horizontal machines is higher, however.

Machine Manufacturer Reputation

If you choose a reputable machine manufacturer, then the quality of the machine will be high. Choosing a high-quality partner and after-sales service will make your machine run smoothly.

Cost Considerations

The price of coffee pouch machines varies widely, based on automation level, capacity, and features. A high-end machine offers more automation and consistency but at a higher initial cost. Balance your budget with your long-term needs, considering not just the purchase price but also the cost of consumables and potential savings on labor.

Machine Maintenance and Upkeep

Regular maintenance is vital for keeping your coffee pouch machine running efficiently. Choose a machine with readily available spare parts and technical support. Factor in the ease of cleaning and maintenance requirements when making your selection.

Implementing Coffee Pouch Machines in Your Operation

Introducing a coffee pouch machine into your operation is an exciting step towards efficiency and growth, but it requires careful planning.

Preparing for the Transition

Ensure your facility is ready for the new equipment by assessing space requirements and electrical needs. It’s also important to plan for any downtime during installation and to prepare your supply chain for new packaging materials.

Training Staff and Ensuring Quality Control

Invest in comprehensive training for your staff to operate the machine safely and efficiently. Establish quality control processes to maintain the consistency and quality of your coffee pouches, which will help in sustaining customer satisfaction and loyalty.

The Future of Coffee Pouch Machines

As technology advances, so do the capabilities of coffee pouch machines. The future is promising, with innovations aimed at increasing efficiency, reducing waste, and improving sustainability.

Innovations on the Horizon

Future machines will likely feature more advanced automation, artificial intelligence for error detection and machine optimization, and even more flexible packaging options to cater to diverse market demands.

Sustainability and Environmental Impact

Sustainability is becoming increasingly important. Expect to see more machines that can handle eco-friendly materials, such as biodegradable and compostable films, alongside technologies that minimize energy consumption and waste.

Conclusion: Embracing the Coffee Pouch Revolution

The coffee pouch revolution is not just about enhancing the shelf life and quality of coffee; it’s about embracing innovation and sustainability in your business operations. By carefully selecting the right machine, preparing your team for the transition, and staying informed about future developments, your business can thrive in the dynamic world of coffee retail. As we look to the future, the potential for innovations in sustainability and efficiency promises to make coffee pouch packaging an even more integral part of the industry.

FAQs

Q1: Can coffee pouch machines handle different types of coffee? A:Absolutely! Whether it’s fine espresso grounds or coarse French press grinds, there’s a machine for every type.

Q2:Are there eco-friendly packaging options available?

A:Yes, many manufacturers like Lintyco Pack now offer biodegradable and compostable pouch options.

Q3: How much does a coffee pouch machine cost?

A:Prices vary widely based on capacity, automation level, and features. Small manual machines can be quite affordable, while large-scale automated systems are an investment.

Q4: Can I customize the pouch design?

A:Definitely. Most machines allow for custom dies and printing options to make your product stand out.

Q5:Is it difficult to maintain a coffee pouch machine?

A:Not if you follow the manufacturer’s guidelines. Regular maintenance is straightforward and essential for longevity.

Q6:How do you package coffee beans?

A: Packaging coffee beans involves these key steps:

- Select Packaging Material: Choose suitable packaging like foil bags or vacuum-sealed pouches to preserve freshness.

- Roast and Cool: Ensure beans cool before packaging to prevent condensation.

- Weigh and Fill: Use precise equipment to portion beans accurately.

- Pack: Fill packaging, remove excess air for vacuum-sealed bags, and seal securely.

- Label: Include essential information such as variety, roast level, and best-before dates.

- Store: Keep packaged beans in a cool, dry place away from sunlight and odors to maintain freshness.

Q7:What is the best way to package coffee?

A: The best way to package coffee depends on factors like shelf life and consumer preferences. Vacuum sealing removes air to preserve freshness, while foil bags create a barrier against light and moisture. Resealable pouches offer convenience for repeated use, and tin tie bags provide traditional yet effective packaging. Glass jars offer airtight storage and visibility for premium coffees. Each method aims to maintain freshness, flavor, and quality.