As a brand owner of food, pet supplies, or daily necessities, are you often troubled by packaging that lacks flexibility, lacks shelf presence, and is susceptible to damage during transportation? In today’s highly competitive retail landscape, consumers’ first impressions often hinge on packaging, and traditional flat bags often fail to meet the multiple requirements of large capacity, stability, and brand presentation.

If your packaging isn’t up to par, your product could be lost on the shelf, losing the attention it deserves. Damage during transportation and storage not only increases return costs but also directly undermines consumer trust in your brand. Bags that lack sufficient display space can hinder your brand story and design, ultimately leading to a loss of both sales and brand value.

The good news is—there are better options on the market. This article will provide an in-depth understanding of the Gusset Bag (gusset bag) and why it has become a popular packaging solution for brands across various industries. From comparisons of different products, practical applications, successful cases from leading brands, and supporting packaging machinery, we’ll gradually reveal how the Gusset Bag can help improve packaging functionality and market competitiveness.

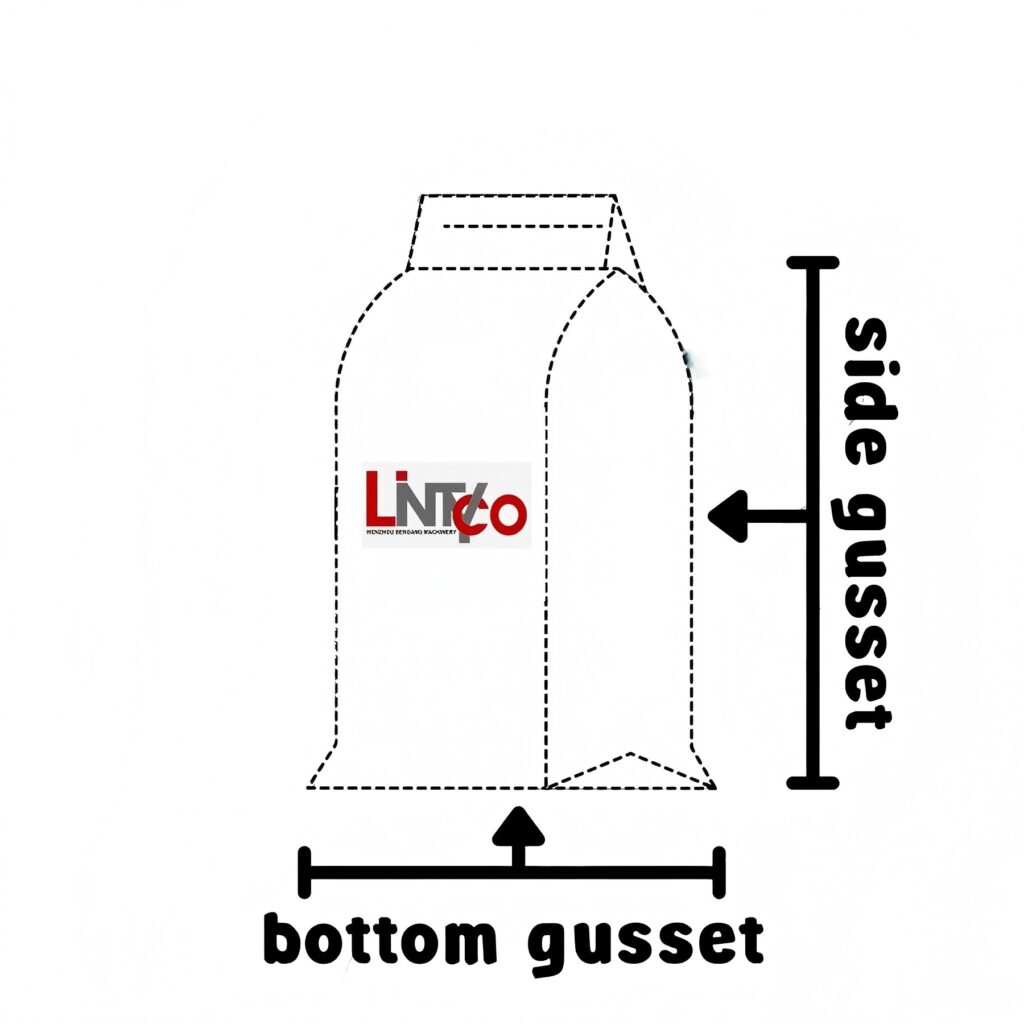

How Many Type of Gusseted Bag?

Bottom Gusset Bags

Bottom gusset bags stand upright instead of lying flat. They offer greater flexibility on shape an size. Not every bottom gusset bag must form perfect box. Since they hold same product volume, a bottom gusset bag’s overall dimensions tend to be larger. Choosing box – pouch style gives you four full panels to showcase your branding an product information.

Bottom gusset bags are especially popular for packaging coffee, pet food, an confections. There are three main variants:

Plow Bottom Gusset Bags

Gussets run along the bottom. This lets the bag stand upright even when lightly filled. You’ll often see this style used for sugar or flour.

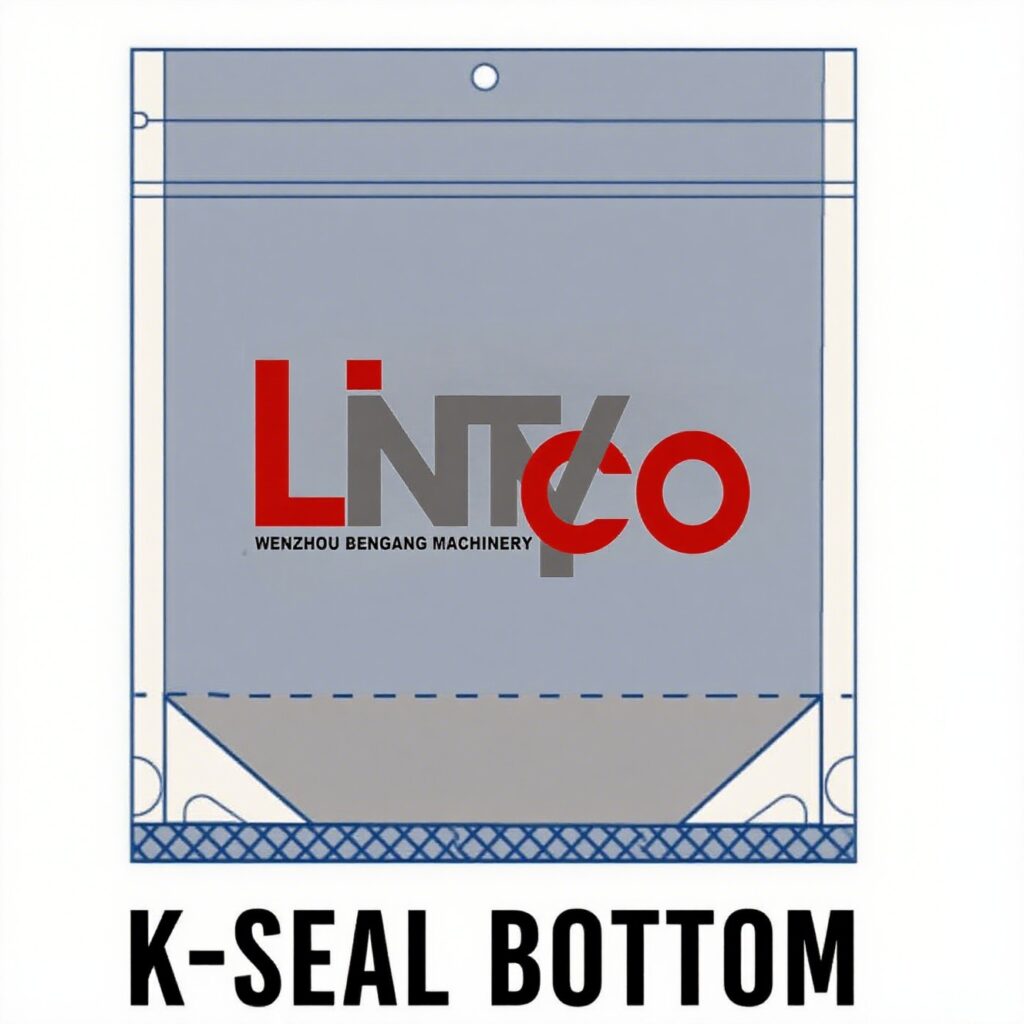

K – Seal Bottom Gusset Bags

A “K” shaped gusset at the base gives extra stability. It’s ideal for medium – to – heavy items like fruits or vegetables.

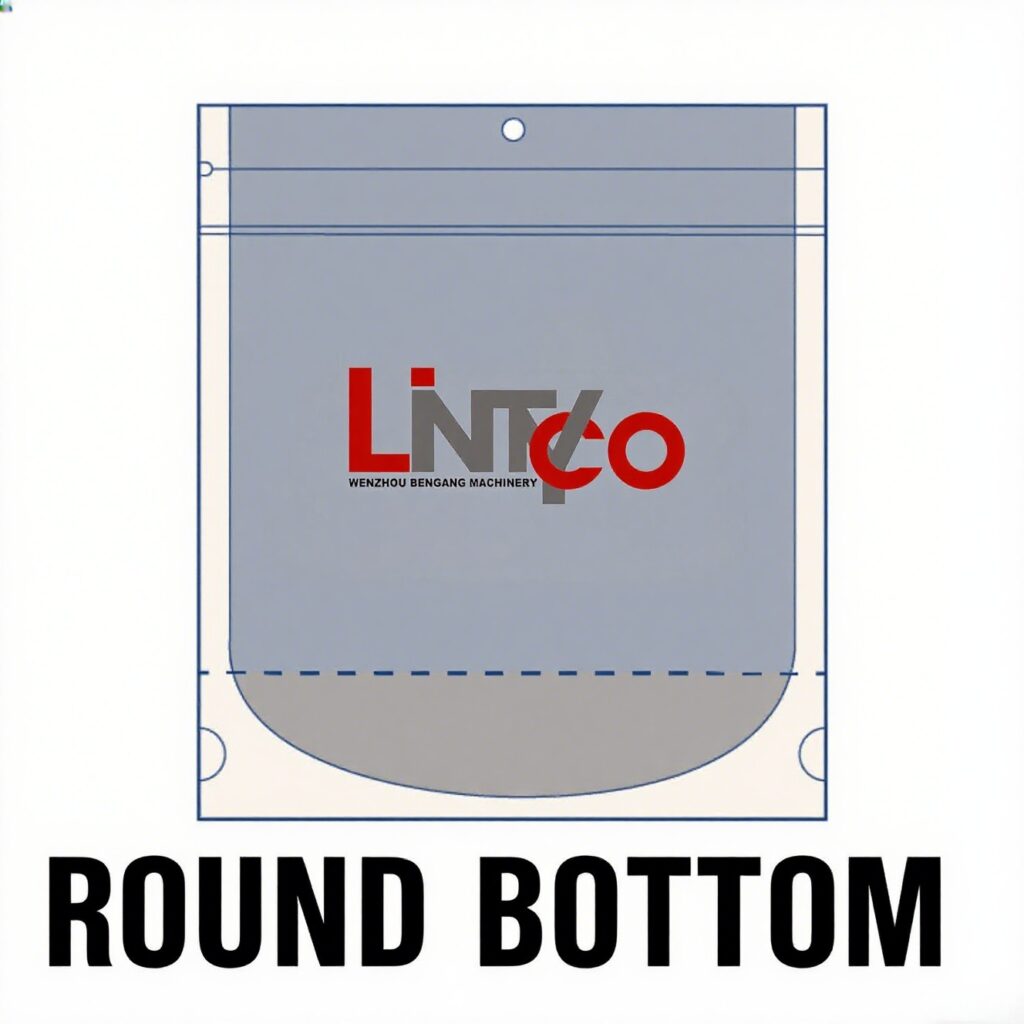

Round Bottom Gusset Bags

The curved bottom gusset is tailored for dry goods such as candies an nuts. It offers a distinctive, rounded profile.

Side Gusset Bags

Side gusset bags have expandable side panels instead of full bottom gusset. This makes them have slimmer footprint on the shelf. Some argue they’re less visually striking when displayed. But side gusset bags actually have ample flat surfaces for branding an product windows. They’re commonly used for dry ingredients, snack foods, an frozen items.

- Standard Side Gusset: Incorporates pleated panels on each side, enabling the bag to expand horizontally. Favored for snacks, frozen foods, and dry ingredients.

- Flat Bottom Side Gusset: Combines side pleats with a flat base for additional vertical stability without the bulk of a full box bottom.

- Euro Slot Gusset: Integrates a hanging slot at the top for retail display, while side pleats allow for lateral expansion.

Choosing the right gusset style depends on your product’s bulk, weight, an presentation goals. What are you selling, an in what quantity? If you have preliminary specifications on mind, request a quote now—we’ll guide you to the perfect gusseted bag for your needs.

Difference Between a Flat Bag and a Gusset Bag?

Flat bags(also called pillow bags)are simple pouches sealed at two ends. Gusset bags have expandable folds that add depth and volume. Key differences:

- Capacity: Gusset bags can hold larger or irregularly shaped items without stressing seals. Flat bags are limited to thinner, more uniform contents.

- Stability: Bottom gusset designs let bags stand upright on shelves—more visible, less space. Flat bags usually lie down, may need extra display fixtures.

- Branding Surface: Gusset bags—especially box pouches—have multiple flat panels for high-impact graphics. Flat bags have minimal printable area.

- Consumer Experience: Gusset bags’ structured shape often feels premium and convenient(easy pouring, resealable zippers). Flat bags can look less robust.

In short, flat bags are simple and cost-effective for lightweight products. Gusset bags offer better functionality, aesthetics, and brand differentiation.

What are Gusset Bag Used For?

Gusset bags are used in many industries thanks to their customizable form and material options.

Food & Beverage

- Coffee & Tea: Box pouches with degassing valves keep freshness and showcase roaster branding.

- Snacks & Confectionery: Side gusset and round-bottom designs make displays attractive—dispensing chips, nuts, candies easy.

- Frozen Foods: Side gusset bags with heavy-gauge films resist punctures and freezer burn—keep product visible.

Pet & Agricultural Products

- Pet Food: Bottom gusset bags handle kibble weight—have tear notches and resealable zippers for convenience.

- Seeds & Grains: Plow bottom bags provide stable bulk packaging for retail and industrial use.

Non-Food Applications

- Hardware & Industrial Components: Side gussets hold oddly shaped parts—minimize movement during transport.

- Retail Merchandise: Euro slot gusset bags combine hanging displays with enough depth for textiles, toys, promotional items.

Gusset bags also work for specialty markets: biodegradable films for eco-brands, multi-layer laminates for barrier protection, high-barrier materials for oxygen-sensitive products.

Why Top 500 Brands Choose Gueest Bag?

Leading global brands leverage gusset bags for several strategic advantages:

- Brand Visibility: Multiple panels and varied shapes create dynamic canvases for storytelling and design, reinforcing brand identity at point of sale.

- Product Protection: Engineered gussets distribute stress evenly, reducing the likelihood of seal failures, punctures, or leakage during shipping and handling.

- Shelf Appeal: Upright-standing and well-defined profiles command attention on crowded shelves, driving higher shelf impact and perceived value.

- Consumer Convenience: Features like resealable zippers, tear notches, and degassing valves enhance user experience, fostering repeat purchases.

- Sustainability Credentials: Many gusset bag formats accommodate recyclable or compostable films, allowing brands to meet environmental commitments without compromising performance.

These benefits help top-tier companies maintain consistent packaging quality across markets, streamline supply chains, and support premium pricing strategies.

Case–German Pet Food Brand Mera

Mera recently upgraded our wet-pouch packaging to a bottom-gusset film containing 30% food-grade recycled polypropylene.

- Virgin plastic usage dropped by 25%.

- They diverted 180 metric tons of plastic waste annually by switching our multi-pack shrink film to paper-based overwrap.

- A 25% increase in puncture resistance versus our previous multi-layer laminate.

- Material costs rose by no more than 5%, while achieving full recyclability.

These initiatives demonstrate that, from a buyer’s standpoint, choosing gusset bags with recycled and mono-material constructions delivers significant sustainability gains, improved package durability, and only minimal cost premiums.

The Packaging Machine Choice for Gusset Bag?

Efficient gusset bag production depends on choosing machinery tailored to bag type, material, output volume.

Form-Fill-Seal(FFS)Machines

- Vertical FFS: Ideal for side and bottom gusset bags—flexible in bag shapes, fast changeovers between formats.

- Horizontal FFS: Suited for rigid materials and high-viscosity contents—often used for pre-made gusset bags needing downstream filling.

Pre-Made Bag Fillers

- Valve Fillers: Pair with box pouches to pack coffee and other degassing products.

- Multi-Head Weighers: Ensure precise portioning for snacks and dry goods into pre-made gusset bags.

Auxiliary Equipment

- Conveyors & Accumulators: Sync bag transport, minimize jams.

- Pick-and-Place Robots: Automate bag loading and case packing for high-throughput lines.

Machine selection depends on material thickness, seal integrity needs, line speed targets, desired automation level. Working with equipment suppliers ensures optimal integration and minimal downtime.

Frequently Asked Questions (FAQ)

What are gusseted bags?

Gusseted bags have extra material on sides or bottom. They can expand to hold larger or irregularly shaped items. This design also gives an stable base. So they’re ideal for bulkier products.

How do I choose the right gusseted bag?

Picking right bag depends on your product’s size, weight, shape. If your product must meet specific standards (like FDA or USDA), discuss compliance with your supplier.

Bottom – gusset bags give extra stability for heavier items.

Side – gusset bags add expansion on sides for more flexible capacity.

Can gusseted bags be customized?

Yes, many manufacturers have an wide range of customization options. They include printed graphics, logos, and functional features like degassing valves or moisture barriers. Customization helps your product stand out on shelf while meeting its storage needs.

How important is machinery in the gusseted bag packaging process?

Machinery is heart of an packaging line. Automated equipment speeds production, ensures consistent sealing & filling, and boosts overall accuracy.

Automation cuts labor needs and boosts throughput a lot.

Regular maintenance—like aligning sensors, lubricating moving parts—keeps machines running smooth and cuts downtime.

Are gusseted bags environmentally friendly?

Environmental impact depends on materials used. Many gusseted bags use recyclable or biodegradable materials. To pick most eco – friendly option, talk with your manufacturer about material formulations.