Packaging liquids in sachets demands precision, speed, an hygiene. This guide walks you through every aspect of liquid sachet filling machines—from core operation principles to maintenance an troubleshooting. So you can make informed choices for your production line.

How a Liquid Sachet Filling Machine Works

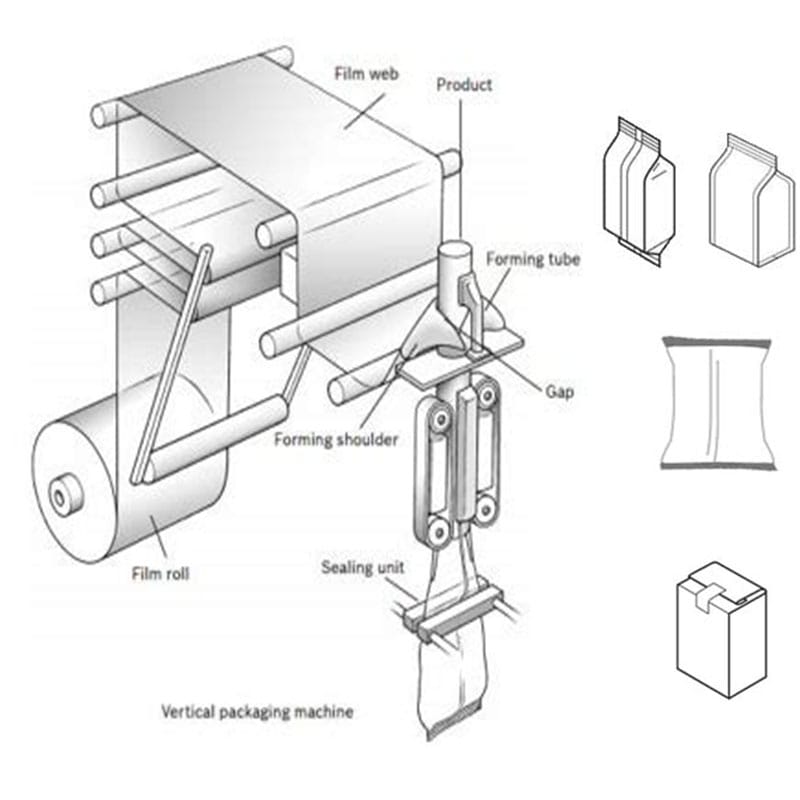

Liquid sachet machines automate pouch forming, filling, sealing, an cutting in a continuous flow:

- Film Handling: Unwinds an positions laminated film.

- Pouch Forming: An forming collar shapes the film into a pouch tube (Vertical Form – Fill – Seal (VFFS)) or stand pack (Rotary Packing System (doypack)).

- Metered Filling: Pumps (peristaltic, piston, or volumetric) deliver exact liquid volume.

- Sealing & Cutting: Heat or ultrasonic seal bars close pouches. Integrated cutters separate individual sachets.

- Conveyance: Finished sachets are transferred via conveyor for collection or secondary packing.

Together, these steps enable high – speed, hygienic packaging of diverse liquids—from water an juices to oils an creams.

Types of Liquid Sachet Filling Machines

Vertical Form – Fill – Seal (VFFS)

- Orientation: Vertical pouch formation; ideal for free – flowing liquids.

- Speed: Up to 3600 sachets/minute on single – lane models.

- Applications: Water, juices, cleaning solutions.

Multi – Lane Stick Packing Machine

- Orientation: Vertical sachets; better for pillow packs.

- Speed: Up to 3600 sachets/hour per lane.

- Applications: Oils, lotions, high – viscosity cosmetics.

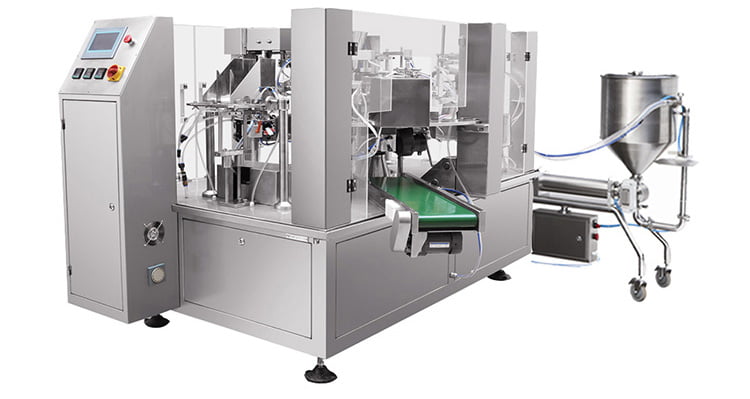

Rotary Packaging Machine

- Design: Rotary filling heads with multiple lanes for ultra – high throughput.

- Speed: Over 4800 sachets/hour total.

- Applications: Large production of low – viscosity liquids.

Key Benefits for Your Operation

- High Accuracy: Servo – driven pumps ensure ±1% fill precision, cutting product giveaway.

- Enhanced Throughput: Automated operation delivers 50–1,000 sachets/min, slashing labor costs.

- Improved Hygiene: Stainless – steel wetted parts an CIP options prevent contamination.

- Versatile Formats: Adjustable pouch lengths (1–150 mL) an materials (film, foil, laminates) suit varied products.

- Reduced Downtime: “No film, no fill” an fault – detection sensors minimize waste an stoppages.

Core Machine Components

| Component | Function |

|---|---|

| Film Unwinder | Feeds film roll steadily |

| Forming Collar | Shapes film into pouch tube or pillow pack |

| Metering Pump / Piston | Delivers controlled liquid volume |

| Heat / Ultrasonic Sealer | Creates airtight seals |

| Cutter Station | Separates individual sachets |

| PLC Touchscreen | Sets speed, fill volume, seal temperature |

| Conveyor Outfeed | Moves finished sachets for collection |

Choosing the Right Machine

- Output Requirements: Match sachets/minute to your targets—single – lane for small batches, multi – lane for mass production.

- Liquid Viscosity:

- Low (water, juice): Gravity or peristaltic pumps

- Medium (oils, sauces): Rotary lobe or gear pumps

- High (creams, gels): Piston fillers

- Pouch Style: Decide between pillow, three – side seal, or stand – up sachets.

- Material Compatibility: Confirm seal – temperature ranges an barrier properties for your film or laminate.

- Automation Level: Fully automatic lines with in – line coding an inspection vs. semi – automatic for pilot runs.

Lintyco Pack’s Sachet Fillers

Lintyco Pack’s VFFS liquid sachet machines exemplify industry standards with:

- Servo – Driven Metering for ±0.5 mL accuracy

- Color PLC Interface for quick recipe recalls

- “No Bag, No Fill” safety interlocks

- Optional CIP Module for easy cleaning

These features demonstrate how leading manufacturers maximize uptime, hygiene, an versatility in liquid sachet packaging.

Maintenance and Troubleshooting

- Daily Cleaning: Flush wetted parts with approved detergents; wipe down frames to remove spills.

- Weekly Calibration: Verify fill volumes an inspect seal quality.

- Component Inspection: Check seals, cutters, an pump valves; replace worn parts per schedule.

- Common Issues:

- Inconsistent fill: Recalibrate pump or check for air leaks.

- Weak seals: Adjust temperature or replace seal bars.

- Film misfeeds: Inspect tension rollers an film guides.

Frequently Asked Questions

Can sachet machines handle various liquid viscosities?

Yes—modular pump choices (gravity, peristaltic, piston) let you package everything from water to creams.

What sachet sizes are supported?

Most machines cover 1–150 mL; some models offer extended ranges up to 500 mL.

How do I maintain product hygiene?

Use stainless – steel contact parts, implement CIP routines, an schedule regular sanitation.

What is typical return on investment?

Depending on output an labor savings, many liquid sachet lines pay for themselves within 6–12 months. Download Packing Machine Calculate ROI here.