In the high-stakes world of modern agriculture, the efficiency of your production line is only as strong as its final stage: packaging. Whether you are processing poultry pellets, aquaculture extrudates, or specialized premixes, the way you bag your product dictates your profit margins, brand reputation, and operational scalability.

For many feed mills and pet food manufacturers across the USA, Europe, and the Middle East, the transition to a modern animal feed packing solution is no longer a luxury—it is a survival strategy.

Why Modern Packaging Matters

Industry feedback and community discussions (such as those found on r/ZeroWaste or r/homestead) highlight that today’s users aren’t just looking for a bag; they are looking for durability, water resistance, and environmental responsibility. Manual bagging is fraught with hidden costs: inconsistent weights leading to “product giveaway,” chronic dust contamination, and a crippling inability to scale when demand spikes.

What Is an Animal Feed Packing Solution?

From Manual Bagging to Fully Automated Packing Lines

In the industry, we define a “solution” as the holistic integration of hardware, software, and workflow.

| Automation Level | Speed (Bags/Hour) | Labor Requirement | Best For |

| Manual Bagging | 100–200 | High (3-5 persons) | Small local farms / Startups |

| Semi-Auto | 300–600 | Medium (1-2 persons) | Growing regional mills |

| Fully Automatic | 800–1,200+ | Low (1 supervisor) | Large-scale industrial plants |

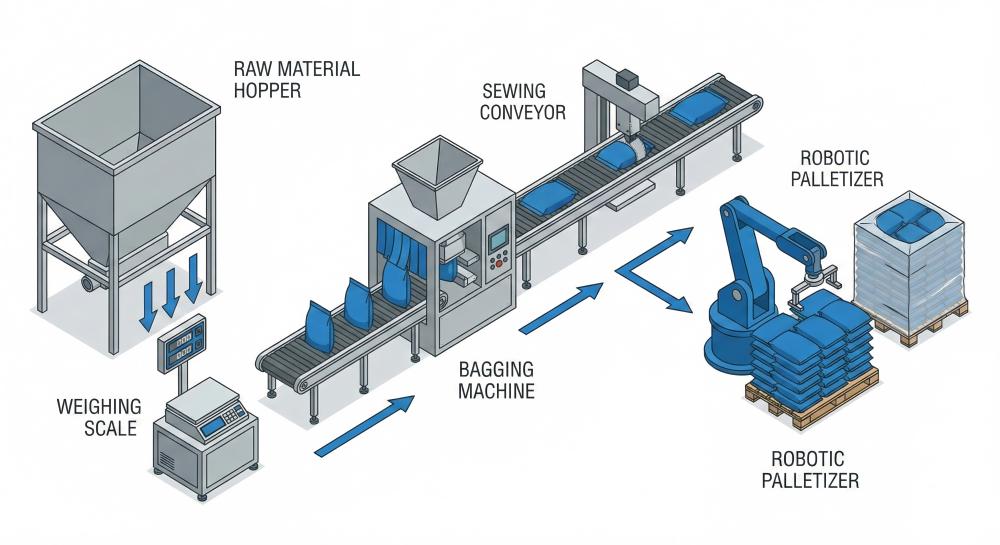

Key Components of a Typical Feed Packing Line

- Weighing System: Utilizing Load cells to ensure precision within a 0.2% margin.

- Feeding & Dosing: Gravity feeders for pellets or Screw conveyors for powders.

- Bag Handling: Automated arms for open-mouth bags.

- Sealing Station: Heavy-duty industrial sewing or heat sealing.

- PLC & Recipe Management: A centralized “brain” (like those used in Lintyco systems) for rapid product switching.

The Packing Process: From Raw Material to Pallet

Material Characteristics & Machine Selection

Not all feed is created equal. Redditors in the agricultural space often point out that “no packaging” is ideal for some fresh products, but for processed feed, the physical properties dictate the machine’s “innards”:

- Pellets & Grains: High-speed gravity feeding.

- Powders & Premixes: Require dust-tight enclosures and screw feeders.

- Oily/Sticky Feed: Needs specialized coatings to ensure smooth flow. For these, waxed paper is often cited as a community-favorite alternative to keep oils contained without heavy plastic.

Types of Animal Feed Packing Machines

Manual & Semi-Automatic Equipment

Best for specialty feeds or low-volume additives.

Fully Automatic Open-Mouth Bagging Machines

The industry standard for 25kg to 50kg bulk packaging. These systems pick an empty bag, fill it, and move it to the sewing head without human intervention.

VFFS & Premade Pouch Series

Specifically for the pet food packaging sector where aesthetics are paramount. Mylar and Silnylon bags are frequently recommended by users for being lightweight, waterproof, and odor-proof—perfect for high-end kibble.

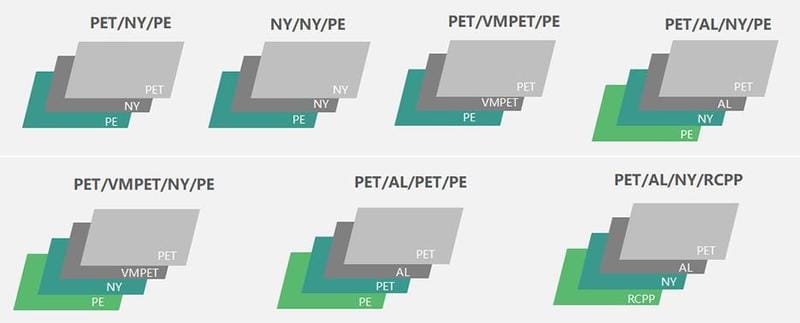

Packaging Materials Comparison

Choosing the right material is a balance between cost, protection, and sustainability. Based on feedback from experienced users and manufacturers:

| Material Type | Pros (Community Insights) | Cons (Real-World Challenges) |

| Plastic (PE/PP) | “Great for waterproofing!” Highly durable for outdoor storage. | Low UV resistance; can disintegrate in the sun. High environmental impact. |

| Cloth/Burlap | Breathable; helps prevent mold. Highly upcycle-able into quilts/totes. | Not water-resistant. Harder to automate at high speeds. |

| Paper-Based | Biodegradable and recyclable. Professional look. | Susceptible to moisture unless lined with plastic or wax. |

| Aluminum/Mylar | Excellent odor-proof barrier and long shelf life. | Higher cost per unit. |

Innovative & Sustainable Trends

The shift toward “Green” is moving from a trend to a requirement.

- Compostable Materials: Utilizing Sugarcane bagasse or cornstarch-based materials.

- Mushroom Packaging: An emerging biodegradable choice using oyster mushroom mycelium on sawdust.

- Reusable Systems: For local delivery, some mills are adopting “deposit” systems for glassware or heavy-duty plastic bins to achieve a Zero Waste workflow.

Overcoming Common Challenges

- Moisture & UV Protection: While plastic is waterproof, it lacks UV resistance. Modern solutions involve UV-stabilized coatings or secondary outer wraps.

- Dust & Safety: Closed-loop filling heads minimize dust, protecting workers from respiratory issues and reducing the risk of dust explosions.

- Quality Tracking: Integrating inkjet coding for Traceability, allowing for easy recalls and batch management.

Why Choose Lintyco for Your Feed Packing Solution?

With over 15 years of expertise, Lintyco bridges the gap between industrial speed and material flexibility.

- Global Reach: Serving markets from China to the USA and Europe, ensuring compliance with diverse safety standards.

- Material Versatility: Our machines are designed to handle everything from traditional PP woven bags to modern, sustainable paper-based alternatives.

- Integrated Automation: We specialize in custom feeding systems that bridge the gap between your production silo and the final bag.

- Scalability: Our PLC systems are built for the future, allowing easy integration with robotic palletizers.

Choosing the Right Feed Packing Solution

When selecting a machine, consider the “Specific Needs” mentioned by the community:

- Capacity vs. Budget: Don’t buy for today; buy for the volume you want in three years.

- Product/Bag Match: If your feed is oily, ensure your machine can handle waxed or foil-lined bags.

- Automation Level: In high-labor-cost regions (US/EU), a fully automatic system usually pays for itself in 18–24 months.

- Sustainability: Is your brand ready to switch to compostable or recyclable options? Ensure your machine is compatible with these thinner or more specialized films.

FAQ – Animal Feed Packing Solution

What is the difference between a feed packing machine and a complete animal feed packing solution?

A feed packing machine usually refers to a single unit responsible for weighing and filling feed into bags.

A complete animal feed packing solution, however, integrates weighing, filling, bag handling, sealing, conveying, palletizing, and control systems into one coordinated production line, designed to improve efficiency, accuracy, and scalability.

How many bags per hour can an automatic feed pellet packing machine handle?

Automatic feed pellet packing machines typically handle anywhere from 300 to over 1,200 bags per hour for 10–50 kg bags.

Actual output depends on factors such as the number of weighers, bag type, sealing method, and overall line automation level.

What bag sizes are most common for animal feed and pet food?

For livestock and poultry feed, 20–50 kg open-mouth bags are the most common.

Pet food and specialty nutrition products usually use smaller packages ranging from 500 g to 10 kg, often with resealable features for consumer convenience.

How accurate are modern animal feed bagging machines?

Modern animal feed bagging machines typically achieve weighing accuracy of around ±0.2% of the target weight.

With proper calibration and maintenance, this level of accuracy significantly reduces product giveaway and improves cost control.

Can one packing line handle both animal feed pellets and pet food kibbles?

Yes, a single flexible packing line can handle both animal feed pellets and pet food kibbles if their flow characteristics and bag sizes are compatible.

Adjustable dosing systems and modular sealing units make such multi-product applications feasible.

What are the best packaging ideas to make animal feed bags stand out on the shelf?

Effective packaging ideas include high-quality printing, clear product windows, resealable zippers, ergonomic handles, and clear formula differentiation by color or icons.

For pet food in particular, attractive branding and functional design strongly influence purchasing decisions.

How do I estimate the ROI of upgrading to an automatic feed packing solution?

ROI can be estimated by comparing labor savings, reduced product giveaway, lower defect rates, and increased throughput against the capital and operating costs of the automated line.

In many feed plants, the typical payback period ranges from 12 to 36 months.

What maintenance does a feed packing machine require?

Routine maintenance includes cleaning product-contact parts, checking belts and sealing elements, calibrating weighing systems, inspecting sensors, and replacing wear parts.

A preventive maintenance plan helps minimize unplanned downtime and extend machine lifespan.

How do I reduce dust and spillage in feed packing lines?

Dust and spillage can be reduced by using sealed dosing chutes, proper drop heights, efficient dust extraction systems, and well-adjusted bag clamps.

Good line design also improves cleanliness and operator safety.

Can Lintyco customize an animal feed packing solution for my existing plant layout?

Yes. Lintyco engineers can customize a complete animal feed packing solution based on your existing plant layout, capacity requirements, bag types, and integration with upstream and downstream equipment.

Conclusion

The next decade will be defined by Industrial 4.0 and the circular economy. We are moving toward “smart packaging” where sensors monitor bag integrity and AI predicts maintenance needs. By investing in a robust animal feed packing solution today, you are securing the future efficiency and profitability of your entire operation.

Ready to modernize your packaging process?

Contact Lintyco’s engineers today for a custom ROI analysis and a tailor-made packaging floor plan.