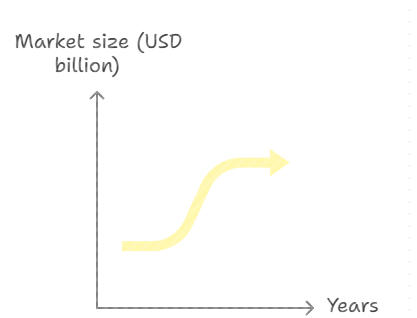

The global sachet packaging market has experienced remarkable growth, with the market valued at USD 9.8 billion in 2025 and projected to reach USD 16.9 billion by 2035, reflecting a stable CAGR of 5.6% during the forecast period. This growth is primarily driven by changing consumer lifestyles, urbanization, and the increasing demand for convenience packaging across emerging economies

4 – side seal sachet packing lines become a versatile workhorse. They let brands deliver precise, attractive single – serve or sample – size packages with little waste. On this guide, we’ll explore how these systems work, their key benefits, critical considerations for selecting right line, and answers to most common questions about implementation and operation.

What Is an 4 – Side Seal Sachet Packing Line?

An 4 – side seal sachet packing line is an end – to – end automated system that forms, fills, and seals small pouches—known as sachets—on all four edges. Unlike pillow (3 – side) packs, four – side seal offers a flat, block – bottom profile before filling, improving stackability and visual appeal.

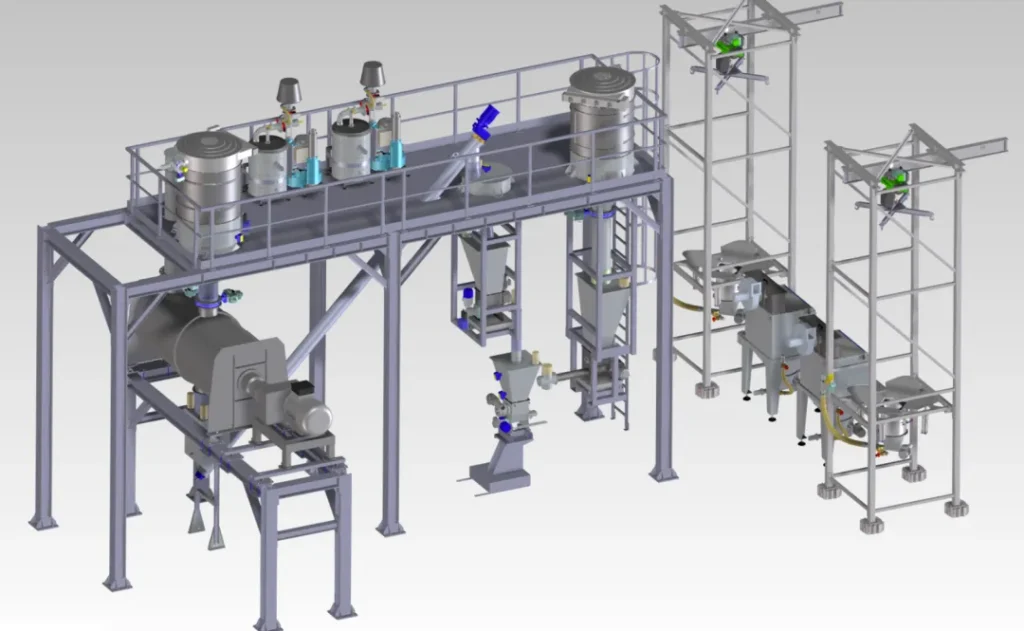

Components of the Line

- Unwinding Station: Holds roll of laminated film.

- Forming Section: Hugs film around a forming shoulder or tube to create sachet shape.

- Filling System: Volumetric cups, auger fillers, or pumps dispense product—powders, granules, liquids, or pastes—into each sachet.

- Sealing Jaws: Heated bars clamp on all four sides, sealing each sachet and cutting it into individual units.

- Control Panel: Programmable logic controller (PLC) with touchscreen HMI for recipe management, speed adjustments, and diagnostics.

Nestlé and Unilever Case Studies

The 4-side seal sachet packaging segment has particularly benefited from this trend. The global 4-side seal machines market is projected to reach USD 3.5 billion by 2033, growing at a CAGR of 6.2% from 2025 to 2033. This growth reflects the increasing demand for efficient and versatile packaging solutions across food and beverage, healthcare, and personal care industries.

Nestlé has significantly expanded its sachet offerings, particularly through its MAGGI brand. The company’s MAGGI Masala-ae-Magic product line, available in 12-sachet share bags, demonstrates the successful implementation of 4-side seal technology for spice blends and cooking aids. In 2024, Nestlé launched 40 new products across multiple categories, many utilizing sachet packaging to reach emerging market consumers.

Nestle has also introduced innovative sachet solutions in nutrition, launching vitamin-fortified, low-cost porridge sachets in Central and West Africa to address food accessibility challenges. This initiative showcases how major brands are leveraging 4-side seal technology for social impact while maintaining commercial viability.

Unilever represents the largest global player in sachet packaging, with the company selling an estimated 53 billion sachets in 2023 – equivalent to 1,700 sachets per second. The company’s Dove brand alone produced 6.4 billion sachets in 2022, accounting for over 10% of Unilever’s total sachet production. This massive scale demonstrates the critical importance of 4-side seal technology in serving emerging market consumers.

However, Unilever’s sachet production has increased by 40% since 2010, highlighting both the growing market opportunity and the sustainability challenges that come with such scale. The company has faced criticism from environmental groups while simultaneously working toward more sustainable packaging solutions.

Industry Applications and Innovation

The food and beverage segment currently holds the largest market share at 41.0% in 2024, driven by increasing demand for convenience foods, condiments, and single-serve products. The pharmaceutical sector is also experiencing significant growth, with companies using 4-side seal sachets for precise dosing and product protection.

Recent technological advancements include the integration of smart packaging technologies, with manufacturers incorporating QR codes, temperature sensors, and tamper-evident features into 4-side seal sachets. These innovations enhance product traceability and consumer engagement while maintaining the cost-effectiveness that makes sachets attractive.

The market is also witnessing a shift toward sustainable materials, with companies developing recyclable and biodegradable sachet solutions to address environmental concerns while maintaining the protective properties that 4-side sealing provides.

Machine Types of 4-Side Seal Sachet Packing Line

There are several types of 4-side seal sachet packing machines, each catering to different production needs and product requirements. Understanding these types can help you choose the right system for your operation:

- Semi-Automatic 4-Side Seal Packing Machines: Ideal for small to medium production scales, these machines require manual film loading and product feeding, but automate sealing and cutting. They are cost-effective and simple to operate.

- Fully Automatic 4-Side Seal Packing Machines: Designed for high-volume production, these integrate film feeding, product filling, sealing, and cutting in a continuous process. They often include touch-screen controls, automatic bag length adjustment, and integrated printing for batch/expiry dates.

- Multi-Lane 4-Side Seal Machines: For businesses needing extremely high throughput, multi-lane systems run multiple sachets simultaneously on parallel tracks. This significantly increases output speed without compromising quality.

- Specialized Filling Machines: These machines specialize by product type—such as powder fillers, liquid fillers, or granule fillers—and are often combined with 4-side seal units to optimize packing accuracy and hygiene.

Optional Devices To Choose

- Code printer: laser marking printer, thermal transfer printer, ribbon code printer, hot stamped coding machine

- Cutting type: straight cut, zigzag cut

- Dosing system: volumetric cup, weigher

- Easy open tear notch features

- Variety of bag sealing patterns and bag shapes

- Automatic counting and repackaging machine: box cartoning machine, vffs vertical form fill machine, premade pouch packing machine

Each machine type can be matched with your product’s specifications, output requirements, and budget to find the perfect solution.

Top Benefits of 4 – Side Seal Sachet Packaging

Versatility Across Products

Whether you’re packaging single – serve coffee, shampoo samples, dental whitening powder, or medicinal granules, an 4 – side seal line can handle diverse viscosities and fill weights with minimal changeover time.

Cost Efficiency and Waste Reduction

- Precise fill control reduces giveaway by filling to exact gram or milliliter.

- Minimal film waste thanks to optimized jaw sealing patterns and programmable film pull settings.

- Low labor requirements—one operator can oversee multiple lines with remote monitoring.

Enhanced Branding and Shelf Impact

Flat, four – side sealed sachets offer a larger printable area on each face, enabling vibrant graphics and clearer brand messaging. The rigid block shape also stands out on crowded retail shelves.

How It Differs from Stand-Up Pouch

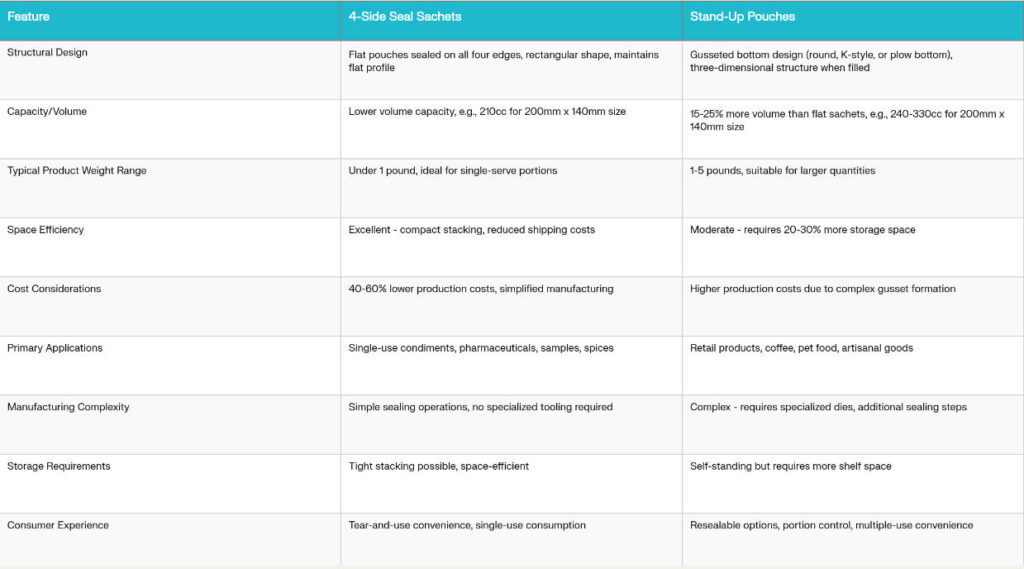

While both 4-side seal sachets and stand-up pouches are flexible packaging solutions, they serve distinctly different purposes and applications. Understanding these differences is crucial for selecting the optimal packaging format for your specific product needs.

Structural Design Differences

4-side seal sachets are flat pouches sealed on all four edges, creating a compact, rectangular package that lies flat when empty. These sachets maintain their flat profile throughout their lifecycle and are designed for single-use applications where space efficiency and cost-effectiveness are paramount.

Stand-up pouches (also known as Doypacks) feature a distinctive gusseted bottom design that allows them to stand upright independently. This bottom gusset can be round (Doyen style), K-style, or plow bottom, depending on the product weight and application requirements. The gusset creates a stable base that expands when filled, giving the pouch a three-dimensional structure..

Capacity and Volume Comparison

The structural differences translate into significant capacity variations. Stand-up pouches typically offer 15-25% more volume than equivalent-sized flat sachets due to their expandable gusset design. For example, a 200mm x 140mm stand-up pouch can hold approximately 240-330cc of product, while a similarly dimensioned 4-side seal sachet holds around 210cc.

This capacity advantage makes stand-up pouches ideal for larger product quantities (1-5 pounds), while 4-side seal sachets excel for portion-controlled, single-serve applications typically under 1 pound.

How to Choose 4 side seal sachet packing line?

Throughput Requirements

Determine your target output—ranging from 30 to 300 sachets per minute. Smaller specialty producers may be satisfied at 30 – 50 ppm, while large CPG brands often require 200+ ppm.

Product Characteristics

- Viscosity and Particle Size: Liquids and pastes may need pump fillers; powders require auger or cup fillers.

- Abrasiveness: Some powders (e.g., coffee) are abrasive and require hardened nozzles.

- Temperature Sensitivity: Heat – sensitive materials may need gentle sealing temperatures and extended cooling sections.

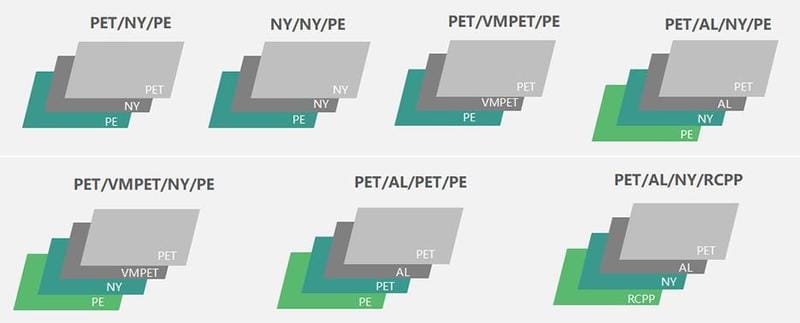

Film Selection and Compatibility

Choose multi – layer laminates (PET/ALU/PE, PET/PE, or OPP/PE) based on barrier needs, seal integrity, and print quality. Confirm machine’s nip rollers and film path geometry match your film thickness (typically 70–200 µm).

Sanitation and Compliance

For food or pharma use, ensure CIP (clean – in – place) capability, FDA – certified contact parts, and optional stainless – steel washdown packages. Look for CE or UL certification for operator safety.

Frequently Asked Questions

Q1: What is the difference between a 3 – side seal (pillow) and an 4 – side seal sachet?

A 3 – side seal pack is sealed on three edges, yielding a pillow shape with two gusset ends that puff out. An 4 – side seal uses four seal jaws to create a flat – bottom block shape, improving shelf presence and print real estate.

Q2: Can I run both powders and liquids on the same machine?

Yes—most modern lines support modular filler stations. However, cross – contamination is a risk, so plan for thorough cleaning and possibly dedicated nozzles or filler modules for each product type.

Q3: How quickly can I change over from one sachet size to another?

Experienced operators can complete a size changeover (splicing new film, adjusting forming shoulder, and sealing jaw settings) in 15–30 minutes, depending on complexity.

Q4: What are the typical ROI timelines?

Most mid – range systems pay for themselves in 12–24 months through labor savings, reduced giveaway, and increased throughput. Custom high – speed lines may see ROI within 9–18 months for large production volumes.

Download Packing Machine ROI Calculator Here.

Q5: How do I ensure my sachet seals are strong and leak – free?

Use high – quality laminates with appropriate sealing layers and set optimal seal temperature, pressure, and dwell time. Regularly inspect T – jaws and replace worn parts. Conduct pull tests on sample sachets daily.