Pillow Pouch Packaging Machine

Pillow Pouch

- Simple to produce

- Reliable sealing helps extend the product shelf life

- Unique pillow shape provides eye-catching brand display space

- Convenient and easy-to-open design

- Customizable packaging forms

- Lower production cost

Pillow Bag Packaging Machine Choice

As experts in packaging machine manufacturing, we are confident in our ability to find the perfect packaging solution for your needs. If you go for stand-up pouches, we suggest using this machinery for packaging:

Vertical Form Fill&Seal Packaging Machine

Suitable for Granules,Powder,Liquid and Special material). Film width:420-730mm Capacity:45-60bag/min . Bag size:W(90-350mm) L(20-450mm)

Premade Pillow Pouch Packaging Machine

Suitable for Granules,Powder,liquid and Special Material. Filling vollum:30-2500g Capacity:25-60 bag/min Big size:W(80-300mm ) L(100-400mm)

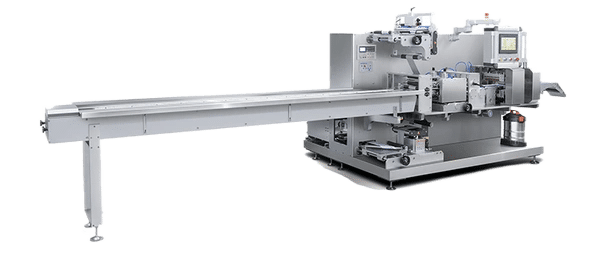

Pillow Pouch Form Fill&Seal Packaging Machine

Suitable for any food,commodity,Medical&Healthy industry. Capacity:30-290per/min. Packing Range:(60-400mm) W(35-100mm). Max width of film:300mm

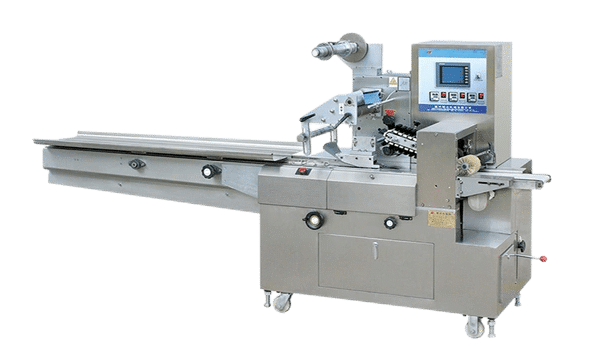

Horizontal Form Fill&Seal Packaging machine

Suitable for food,non-food industry and pharmaceuticals.Capacity:80-120 per/min .Packing Range:L(100-280mm),W(85-160mm) Max width of film:400mm

Description

Pillow Bags are soft, rectangular packaging bags for pillows. It is usually made of flexible plastic materials like polyethene or polypropylene, which can be easily shaped into different shapes and sizes. You can use Pillow Bags to package a variety of products, like snacks, candies, or bakery goods.

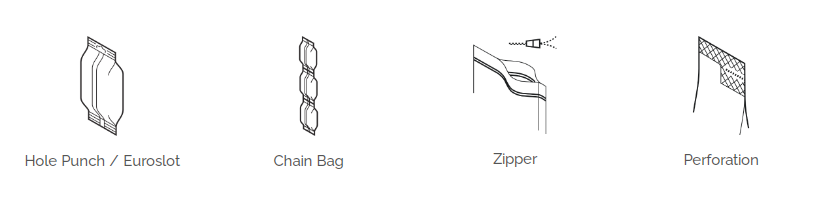

Custom options

FAQ

| Pillow Bag | Regular Plastic Bag |

|---|---|

| Structure: Features 3- or 4-side seals for reinforced durability | Typically single-layer with basic side seals |

| Material: Multi-layered films (e.g., PET/AL/PE) for moisture/oxygen resistance | Often made of thin, single-layer polyethylene |

| Functionality: Customizable with zippers, windows, or resealable features | Limited functional features |

| Aesthetic: Designed for branding with printed graphics | Minimal branding options |

| Applications: Ideal for automated packaging of food, powders, and industrial products | Generic use for lightweight items |

- Food: Snacks, coffee, spices, frozen goods, and pet food

- Liquids/Powders: Sauces, honey, protein supplements, and chemicals.

- Retail: Jewelry, cosmetics, and single-serve samples

- Industrial: Hardware components, automotive parts, and agricultural seeds.

- Material: Opt for multi-layer laminates (e.g., PET/AL/PE) for moisture/oxygen barriers

- Seal Integrity: Ensure heat-sealed or ultrasonic-sealed edges for leak-proof protection

- Certifications: Verify food-grade (FDA) or sustainability standards (BPA-free)

- Customization: Prioritize suppliers offering resealable zippers, tear notches, or transparent windows

Yes, puffy bags (quilted, marshmallow-like designs) are a rising trend:

- Fashion Appeal: Popularized by luxury brands like Prada and Chanel for their playful, cushioned aesthetics

- Functional Comfort: Lightweight and adaptable for travel or urban use

- Sustainability Alignment: Some versions use recycled materials

- Market Growth: Increasing adoption in casual and high-end markets

| 4-Side Seal Bag | 3-Side Seal Bag |

|---|---|

| Reinforced gussets and flat base for stability | Lay-flat design for space efficiency |

| Higher capacity for bulky/heavy items (e.g., pet food) | Ideal for lightweight, compact products (e.g., snacks) |

| More material usage (15–20% higher cost) | Cost-effective for high-volume production |

- Cost Efficiency: Lower production costs vs. rigid packaging

- Customization: Branding-friendly with print and functional add-ons

- Protection: Multi-layer barriers against moisture, UV light, and contaminants

- Automation-Friendly: Compatible with vertical form-fill-seal machines (40–230 bags/minute)

| Pillow Bag | Doypack Bag |

|---|---|

Lay-flat design for efficient storage |

Stand-up “W” gusset base for shelf presence |

Lightweight and space-saving |

Heavier due to reinforced structure |

Ideal for dry goods and powders |

Better for liquids and retail displays |

Lower material usage |

Higher barrier options (e.g., aluminum foil) |

Choose Pillow Bags for cost-sensitive, high-volume packaging (e.g., snacks), and Doypacks for premium liquid products requiring shelf visibility

High-quality Guarantee

We strictly control the quality of every process from raw materials to finished products, use GMI color management system for printing to ensure color consistency.

Our plant has been certified by ISO 9001:2015, ISO 14001:2015, ISO22000:2018, BRC, BSCI, and GMI to ensure high quality and food safety

To guarantee high quality and food safety, the below items are strictly tested in the in-house laboratory:

Learn more

If you have the model you are interested in, please check it machine catalog

if you have the corresponding material, please go to Industry to choose.

If you are interested in a different pouch style, please click here to Pouch style

The quickest way to choose the best packing solution is to contact us directly, don’t hesitate!

Free Service to help calculating the return on investment of a potential packaging machine purchase? Get it Now!