Doypack Pouch Packaging Machine

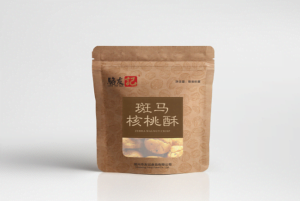

Doypack Pouch

- Custom shapes and sizes to fit your needs

- Doypack Pouch with zipper enables multiple reclosing, retaining food fresh and crisp

- Level underside means easier filling

- Stand-up pouches with a flat bottom and resealable zipper or spout design

- Constructed from various materials like laminates, foils and polymers

- Custom shapes and sizes to fit your needs

- Branding/info available

Doypack Pouch Packaging Machine Choice

As specialists in packaging machine manufacturing,we are confident in our ability to determine the optimal packaging solution for your needs. If you select stand up pouches, we would suggest the following machinery for packaging:

Stand Up Pouch Packaging Machine

Suitable for Granules,Powder,liquid and Special Material. Filling vollum:30-2500g Capacity:25-60 bag/min Big size:W(80-300mm ) L(100-400mm)

Bag Description

The Doypack variety of self-standing pouch packaging is gaining popularity for premium goods such as pet food, coffee, cannabis and nibbles because of its minimal and appealing look. This packaging form can differentiate your product from rivals courtesy of its striking styling. With the pre-made Doypack, filling and sealing can be conveniently accomplished on a Premade Pouch Packaging Machine.

Customer Option

FAQ

The term “Doypack” originated from the French company Doyen, which developed this packaging style in the 1960s.The name combines “Doyen” with “pack,” emphasizing its innovative design that combines flexibility with stability. Doypacks are characterized by a flat, gusseted base that allows the pouch to stand upright, distinguishing them from traditional flat pouches

| Doypack Pouches | Three-Side Seal Pouches |

|---|---|

| Stand upright with a reinforced base or gusset (e.g., U-shaped, K-seal, or corner bottom) | Lay flat and require external support for display |

| Ideal for liquids, semi-liquids, and heavy products (e.g., sauces, pet food) | Better for lightweight, dry products (e.g., snacks, powders) |

| Higher barrier properties (e.g., aluminum foil layers) for extended shelf life | Simpler structure with fewer material layers |

| Customizable with spouts, zippers, or windows | Limited functional features (e.g., basic tear notches) |

| Higher production cost due to complex sealing and materials | Cost-effective for high-volume packaging |

- Material Choice: Use films compatible with printing (e.g., PET, BOPP, recyclable PP)

- Printing Methods:

- Flexographic Printing: High-speed, cost-effective for large batches

- Digital Printing: Ideal for short runs and intricate designs

- Flexographic Printing: High-speed, cost-effective for large batches

- Design Customization:

- Include logos, instructions, and barcodes across all four panels

- Add functional elements (e.g., resealable zippers, tear notches) during production

- Include logos, instructions, and barcodes across all four panels

- Post-Printing Treatments: Apply gloss/matte finishes or spot UV for visual appeal

- Horizontal Form-Fill-Seal (HFFS) Machines: Form pouches from roll film, fill, and seal at speeds up to 100 bags/minute

- Vertical Form-Fill-Seal (VFFS) Machines: For lightweight products like snacks

- Gusseting Systems: Create the base structure (e.g., U-shaped or K-seal)

- Spout/Zipper Attachments: Add resealable closures or dispensing spouts

- Printing and Lamination Units: Apply graphics and barrier layers (e.g., aluminum foil)

- Shelf Presence: Upright display maximizes visibility in retail settings.

- Material Efficiency: Use 50–70% less plastic than rigid containers.

- Product Protection: High-barrier materials block moisture, oxygen, and UV light.

- Convenience: Resealable zippers and spouts for easy dispensing.

- Sustainability: Recyclable monomaterial options (e.g., PP) align with eco-friendly goals

- Versatility: Suitable for liquids, powders, and heavy items (e.g., pet food)

- Material Selection:

- For liquids: Opt for aluminum foil or metallized PET laminates

- For eco-conscious brands: Choose recyclable PP or compostable kraft paper

- For liquids: Opt for aluminum foil or metallized PET laminates

- Seal Integrity: Ensure heat-sealed edges are leak-proof and durable

- Certifications: Verify food-grade (FDA) or sustainability certifications (e.g., ISO 14001)

- Supplier Expertise: Prioritize manufacturers with ISO compliance and customization capabilities

- Functional Features: Select zippers, spouts, or windows based on product needs

High-quality Guarantee

We strictly control the quality of every process from raw materials to finished products, use GMI color management system for printing to ensure color consistency.

Our plant has been certified by ISO 9001:2015, ISO 14001:2015, ISO22000:2018, BRC, BSCI, and GMI to ensure high quality and food safety

To guarantee high quality and food safety, the below items are strictly tested in the in-house laboratory:

Learn more

If you have the model you are interested in, please check it machine catalog

if you have the corresponding material, please go to Industry to choose.

If you have interested in another pouch style, please click here to Pouch style

The quickest way to choose the best packing solution is to contact us directly, don’t hesitate!

Need help calculating the return on investment of a potential packaging machine purchase? We’re here to help.