Back Seal Bag Packing Machine

Back seal bag

- Cost-efficient choice vs other types

- Premium prints

- Effortless tear tabs, zip locks to re-close, flattened undersides

- Little space required

Back Seal Bag Packing Machine Choice

As specialists in packaging machine manufacturing,we are confident in our ability to determine the optimal packaging solution for your needs. If you select stand up pouches, we would suggest the following machinery for packaging:

Vertical Form Fill&Seal Packaging Machine

Suitable for Granules,Powder,Liquid and Special material). Film width:420-730mm Capacity:45-60bag/min . Bag size:W(90-350mm) L(20-450mm)

Premade Pouch Packaging Machine

Suitable for Granules,Powder,liquid and Special Material. Filling vollum:30-2500g Capacity:25-60 bag/min Big size:W(80-300mm ) L(100-400mm)

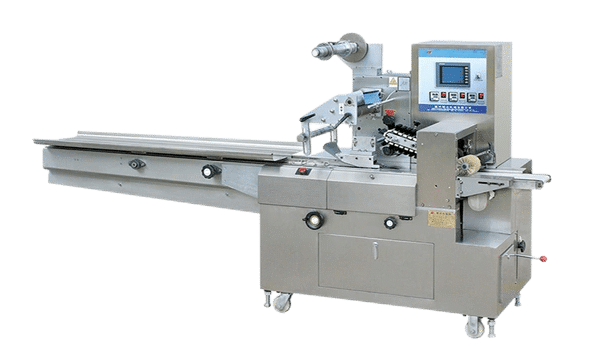

Pillow Form Fill&Seal Packaging Machine

Suitable for any food,commodity,Medical&Healthy industry. Capacity:30-290per/min. Packing Range:(60-400mm) W(35-100mm). Max width of film:300mm

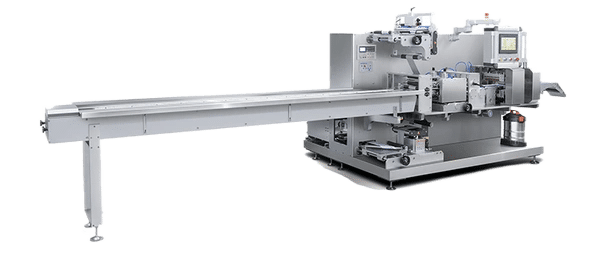

Horizontal Form Fill&Seal Packaging machine

Suitable for food,non-food industry and pharmaceuticals.Capacity:80-120 per/min .Packing Range:L(100-280mm),W(85-160mm) Max width of film:400mm

Bag Description

• A back seal bag has a seal at the rear base, standing up and used for food, with maybe a tear strip or zipper.

• Employed to package snacks, coffee and such, a back seal pouch with a bottom back seal allows display upright plus re-closing

• The back located seal of this bag type enables upright standing, used for teas and dried goods, and potentially featuring easy open/re-seal means.

FAQ

A BACK seal bag (also called a back-sealed pouch ) is a type of flexible packaging where the bag is sealed along three edges (two sides and the bottom), with the back edge formed by folding the film. This design creates a flat, stable base for upright storage and efficient stackingibus leo.

Advantages:

- Enhanced Stability: The flat base allows the bag to stand upright, ideal for retail displays.

- Strong Seals: Multi-layer materials (e.g., PE, aluminum foil) provide tear resistance and protect contents from moisture, oxygen, and contamination.

- Cost-Efficiency: Uses less material compared to four-side seal bags, reducing production costs.

- CustomizabilitySupports branding with printed designs and functional features like resealable zippers

- Dry Foods: Coffee, rice, snacks, spices, and pet food.

- Granules/Powders: Pharmaceuticals, protein supplements, and detergent.

- Liquids/Semi-Liquids: Sauces, honey, and personal care products (e.g., shampoo).

- Industrial Items: Hardware components, screws, and small parts

Materials:

- Base Layers: Polyethylene (PE), polypropylene (PP), or PET for flexibility and durability.

- Barrier Layers: Aluminum foil or metallized films for moisture/oxygen protection.

- Specialty Options: Recyclable PP/RCPP for sustainability or UV-resistant coatings.

Customization:

- Printing: Logos, product info, or barcodes can be added.

- Functional Features: Resealable zippers, tear notches, or anti-static layers.

- Size/Shape: Adjustable dimensions to fit product requirements

Production Equipment:

- Vertical Form-Fill-Seal (VFFS) Machines: Automatically form, fill, and seal bags from film rolls.

- Heat Sealers: For creating strong side and bottom seals.

- Material Handling: Rollstock film unwinders and tension control systems.

Filling Equipment:

- Volumetric Cup Fillers: For precise dosing of granules or powders.

- Liquid Fillers: Piston or pump-based systems for sauces or liquids.

- Counting Systems: For hardware items like screws or bolts

- Speed & Capacity:

- Low-volume: Semi-automatic machines (e.g., manual heat sealers).

- High-volume: Automated VFFS machines (30–60 bags/minute).

- Material Compatibility: Ensure compatibility with films like PE, PET, or aluminum laminates.

- Sealing Technology:

- Heat Sealing: Standard for most applications.

- Ultrasonic Sealing: For thicker or multi-layer films.

- Custom Features:

- Adjustable bag dimensions (e.g., 30–120 mm width).

- Integrated printers for date coding or branding.

High-quality Guarantee

We strictly control the quality of every process from raw materials to finished products, use GMI color management system for printing to ensure color consistency.

Our plant has been certified by ISO 9001:2015, ISO 14001:2015, ISO22000:2018, BRC, BSCI, and GMI to ensure high quality and food safety

To guarantee high quality and food safety, the below items are strictly tested in the in-house laboratory

Learn more

If you have the model you are interested in, please check it machine catalog

if you have the corresponding material, please go to Industry to choose.

If you have interested in another pouch style, please click here to Pouch style

The quickest way to choose the best packing solution is to contact us directly, don’t hesitate!

Need help calculating the return on investment of a potential packaging machine purchase? We’re here to help.