Picture this: a customer cracks open your bag and a wave of aroma hits—bright, sweet, alive. That moment isn’t luck. It’s the result of choosing a coffee packaging solution that protects flavor, survives shipping, and tells your brand story at a glance. Below, I’ll walk you through materials, formats, design, and sustainability—with real-world tips you can use on your next production run. We’ll naturally touch on airtight coffee containers, flexible coffee packaging, coffee bag packaging, and the coffee packaging materials and coffee packaging design decisions that matter most.

Understanding Coffee Packaging Solutions

Why Packaging Matters (beyond looking good)

Coffee is fussy. Oxygen and moisture flatten flavors; heat and light speed things up. Good packaging acts like a tiny climate system—slowing staling, letting CO₂ out without letting O₂ in, and surviving the bumps between your roaster and your customer. Bonus: it’s a 24/7 brand ambassador on the shelf and in an unboxing video.

The Main Material Families—when each makes sense

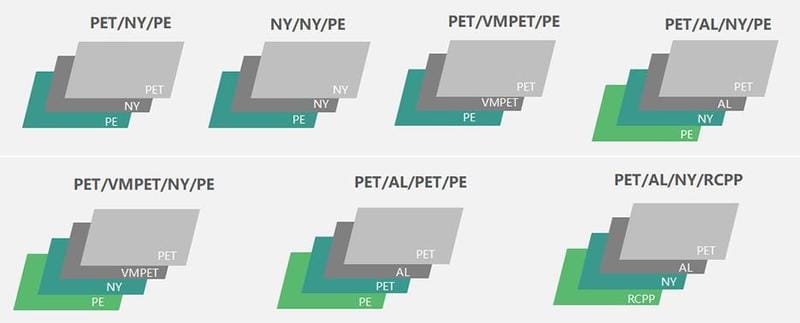

- Multi-layer laminates (e.g., PET/AL/PE or PET/MetPET/PE) Best overall barrier for longer shelf life or slow turnover. Print quality is excellent. Use when: you ship far, stock multiple months, or sell delicate, high-aromatic lots.

- Paper + inner barrier Warm, craft-forward look; pair with a strong inner film to avoid staling. Use when: aesthetics matter and your turnover is steady.

- Rigid tins/canisters (airtight coffee containers) Extremely protective and premium; pricier and bulkier. Use when: giftable SKUs, limited releases, cafe displays, or refill programs.

- Compostable/mono-material films Great story, improving fast; validate OTR/WVTR before launch. Use when: you can test and confirm they meet your shelf-life goal.

PS: Flexible coffee packaging (stand-up pouches, side-gusset bags, flat-bottom bags) is the workhorse: light to ship, easy to brand, and friendly to filling lines. Add the good stuff—one-way degassing valves, resealable zippers, tear notches—and you’ve got function plus shelf presence.

Criteria for Selecting Packaging

Freshness & Aroma: the non-negotiables

- Barrier: Aim for low OTR/WVTR. If your coffee takes >4 weeks to reach the cup, choose higher-barrier films (foil or high-barrier metallized).

- Valve: Beans keep off-gassing for days. A reliable valve prevents pillow-bags and flavor drift.

- Seals: A beautiful bag with weak seals is a leaky boat. On larger bags, target wider seals (≈8–10 mm) and verify with peel tests.

- Headspace: If you can, nitrogen flush. If not, keep fills consistent and bags upright during cool-down.

60-second explanation of OTR: lower number = slower oxygen sneaking in = longer your fruit and florals stick around.

Airtight Coffee Containers vs. Traditional Bags

- Airtight containers Feel great in the hand, stack well, and really are “set-and-forget” for freshness. More expensive and heavier to ship. Think: premium, giftable, keep-at-home refills.

- Traditional laminated bags Cheaper per unit, flexible for SKUs and promos, and easy to store by the pallet. Need solid seals and valves. Think: your core line-up, e-commerce, wholesale.

Practical combo: ship in pouches; offer a branded container for subscribers to refill. It’s sustainable, looks nice on kitchen counters, and nudges repeat purchase.

Durability & Everyday Use (the unsexy stuff customers notice)

- Closures that re-seal cleanly after the fifth open.

- Tear notches that actually tear straight.

- Valves that don’t weep oils.

- Clear roast/best-by and batch codes (saves you during a support ticket).

Coffee Packaging Design Elements

Aesthetic vs. Practical (you shouldn’t have to choose)

Use your top third for brand + the single most important claim. Put the coffee story (origin, process, flavor notes) in the middle where eyes land next. Reserve the bottom/back for brew tips, sustainability notes, and compliance. Finishes like matte, soft-touch, or spot gloss work fine with high-barrier films—no need to sacrifice shelf life for looks.

Branding that feels like a conversation

- Write a tiny “Meet this coffee” blurb in human terms: “Juicy and floral—think nectarine and jasmine.”

- Add a QR to a 60-second brew video; show grind size and pour rhythm.

- Use simple icons for roast level, brew methods, and sustainability credentials.

Eco-friendly, without greenwashing

- Prefer mono-material (PE/PP) where recycling is real in your markets.

- Light-weight if you can, but test that seals still hold.

- If you claim “compostable,” specify home vs industrial and give disposal guidance.

- Consider PCR (post-consumer recycled) content where food-contact rules allow.

Type of Coffee Bag Packaging

Type of Packaging Style

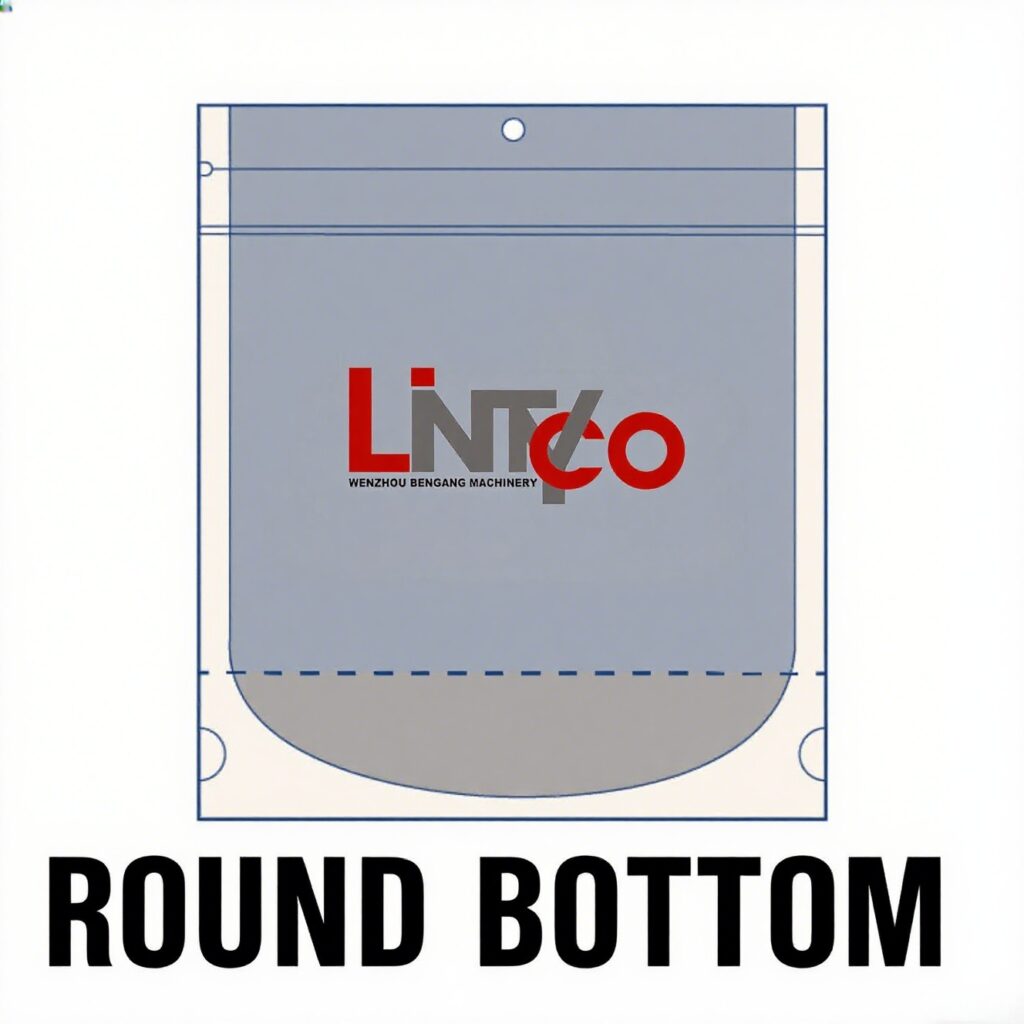

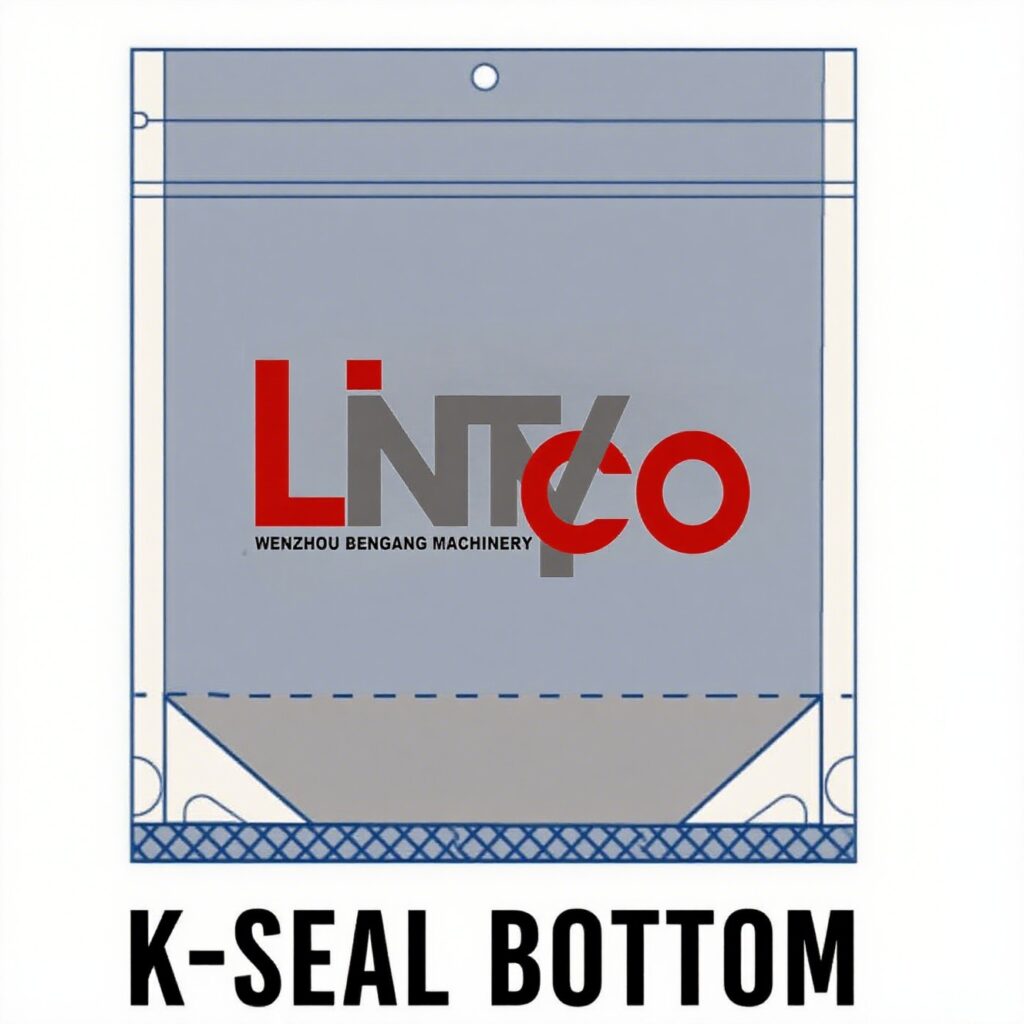

- Stand-up pouch (Doy): Great for 6–12 oz retail; stands nicely while customers scoop.

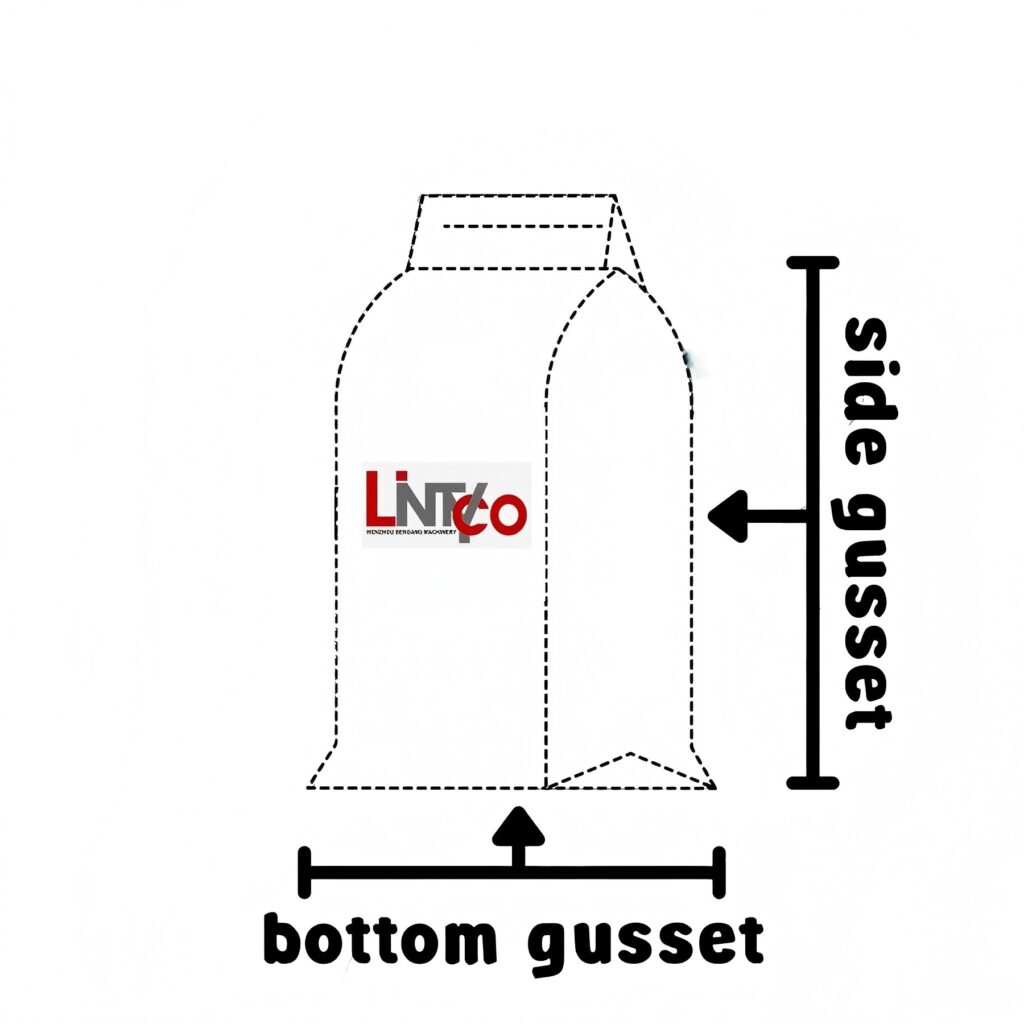

- Side-gusset: Efficient for 12 oz–5 lb; cubes out well in boxes for wholesale.

- Flat-bottom/box pouch: Premium, stackable, and planogram-friendly for grocery.

What makes stand-up pouches a crowd favorite

They look proud on a shelf, photograph well online, and keep the kitchen tidy. Add a zipper and valve, and your customer’s daily ritual feels effortless.

Small innovations that pull their weight

- Valve-less micro-channels (some mono-materials) to simplify recycling.

- Zipper-free roll-down closures on certain recyclable films.

- Smart labels that unlock roast curves, farm stories, or freshness timers.

Successful Brands and Their Packaging Choices

- Blue Bottle Coffee uses matte-black rigid tins for specialty blends, reinforcing premium positioning.

- Stumptown Coffee Roasters employs stand-up pouches with one-way valves and vibrant graphics to convey origin stories.

Lessons Learned from Packaging Failures

- Over-engineered multi-layer laminates without degassing valves led to bag swelling and customer complaints.

- Unvalidated compostable films resulted in premature staling due to elevated WVTR.

How to Pick Your Coffee Packaging Solution

Start from the cup you want your customer to taste four to six weeks after roast. Choose the barrier that protects that cup, then pick the format that fits your channel and story. Invest in the details customers touch—zippers, notches, legible dates—because those are the moments they remember.

A simple 30-day plan

- Week 1—Audit: Gather OTR/WVTR specs, seal failure rates, return reasons, and shelf-life complaints.

- Week 2—Prototype: Two materials (metallized vs mono-material) × two formats (stand-up vs flat-bottom). Add/review valves and closure.

- Week 3—Field test: Ship test orders to hot/humid and cool/dry addresses. Track swelling, seal integrity, and customer comments.

- Week 4—Decide & document: Lock the winner, finalize artwork, and write a one-page “packing SOP” for your team.

Handy extras you can copy-paste

Supplier email template

Hi [Name], we’re testing a new coffee bag packaging setup. Could you quote:

- Material A: PET/MetPET/PE (high-barrier) and Material B: mono-PE (recyclable)

- 12 oz stand-up and 2 lb side-gusset with one-way valve + zipper

- Target seal width 8–10 mm; please share OTR/WVTR at 23°C/50% RH and 38°C/90% RH

- Lead times, MOQ, unit pricing at 5k/20k/50k, color limits for matte/soft-touch

Thanks! We’re aiming to pilot next month.

QC checklist (receive & pack)

- Visual: print, lot code, valve alignment

- Seal test: peel strength spot checks

- Valve function: no oil weeping; bags not “pillowing” after 48–72h

- Drop test: cases from pallet height; no seam failures

- Label: roast date, best-by, batch code legible