Ever opened a bag of popcorn only to find it tastes like chewy cardboard? We’ve all been there.

Americans devour over 17 billion quarts of popcorn every single year, which means your product has to stay perfectly crunchy and flavorful to stand a chance—something only possible through a strictly airtight packaging environment.

For Food manufacturers, that “stale” moment is a brand killer. Getting popcorn from the popper to the consumer in peak condition isn’t just about a bag and a staple, it’s a growth of your food brand.

Why does popcorn packaging require such special handling?

Popcorn is a “diva” product that demands breakage control, precise weighing for low-density kernels, strict moisture management, and absolute protection from oxygen and oil-induced seal failures.

Popcorn is a pain to package. Here is why:

- Fragility: Those fluffy kernels break under the slightest pressure, leading to “popcorn dust” at the bottom of the bag.

- Low Density: Because it’s so light (typically 30–60 g/L bulk density), traditional gravity-fed scales often struggle with accuracy.

- Oil vs. Seals: Most popcorn is coated in oil or butter. If that oil touches the sealing area, the bag won’t close properly, and your shelf life vanishes.

- Moisture Sensitivity: Popcorn easily absorbs environmental humidity. Even small moisture migration can destroy crispness.

- Oxygen Sensitivity: Oxygen is the ultimate enemy. It causes staling and lipid oxidation, which kills the crunch and flavor.

For export-oriented brands, controlling residual oxygen, moisture content (ideally below 3%), and seal integrity becomes a technical requirement—not just a quality preference.

This is exactly why we need to talk about nitrogen.

What are the most popular types of popcorn packaging bags?

The market currently favors Pillow bags for cost-efficiency, Gusset bags for shelf presence, Premade Doypacks for premium branding, and high-barrier laminated films for extended shelf life.

Pillow Bags: The “old reliable.” Most common and cheapest to produce. Ideal for high-speed VFFS production.

Gusset Bags: These offer more volume and a squared-off look that stands better on shelves.

Premade Doypack (Stand-up Pouch): If you’re selling “gourmet” or “artisan” popcorn, this is your go-to. They look expensive because they are.

Classic Microwave Popcorn Bag:it’s a feat of engineering. Unlike a standard vertical packing machine bag, this one has a specific job—it has to be a pressure cooker and a serving bowl all in one.

Family Size Big Bags: For those movie marathons at home.

High-Barrier Laminated Bags (PET/PE, BOPP/CPP, or Metallized Film): Recommended for nitrogen-flushed popcorn to minimize oxygen transmission rate (OTR) and moisture vapor transmission rate (MVTR).

Why is nitrogen flushing absolutely critical for your brand?

Nitrogen flushing replaces oxygen inside the bag to prevent oxidation, maintain crispness, reduce kernel breakage, and significantly extend shelf life.

If oxygen stays in the bag, your popcorn will lose its flavor and crunch before it even hits the retail shelf. In export markets, uncontrolled oxygen levels are one of the main causes of product returns.

| Standard | Oxygen Level Target | Result |

|---|---|---|

| Commercial Standard | < 3% | Standard shelf life |

| High-End Brands | < 2% | Premium freshness & longer export life |

Research on modified atmosphere packaging (MAP) for fried and puffed snacks indicates that keeping residual oxygen below roughly 2% can dramatically reduce the formation of oxidation markers such as hexanal during storage. This is why premium popcorn brands targeting long retail distribution or export markets typically design their systems around strict oxygen control thresholds.

In a Vertical Form Fill Seal (VFFS) machine, this works via gas injection nozzles right before the final seal. You have to balance the gas-to-product ratio perfectly; too much gas and the bag looks like a balloon ready to pop; too little, and the popcorn goes stale.

If you’re serious about popcorn, you can’t just use a generic single-layer poly bag. Why? Because as we mentioned, popcorn is extremely sensitive to oxygen and moisture, which leads to staling and loss of crunch

For higher precision applications, advanced systems include:

- Dual-nozzle nitrogen injection for more uniform gas distribution

- Residual oxygen analyzers for inline O₂ monitoring

- Gas flow control valves to stabilize internal pressure

What types of popcorn packing machines should you consider?

Choosing between a VFFS machine and a Rotary Pouch machine depends entirely on your bag style, production volume, and branding strategy.

Vertical Form Fill Seal (VFFS): Great for pillow and gusset bags. It’s fast (40–120 bags/min), efficient, compact, and easily integrates nitrogen systems. Ideal for mass production.

Rotary Premade Pouch Machine: Best for Doypacks and zipper bags. It offers high seal strength, better aesthetics, and stable performance for high-end retail products.

Fully Automatic Popcorn Packaging Line: This is the “set it and forget it” solution, including multi-head weighers, nitrogen generators, check weighers, metal detectors, and case packers.

For low-density popcorn, pairing the machine with a multi-head weigher (10–14 heads) ensures ±0.5–1.5g accuracy, reducing giveaway and improving cost control.

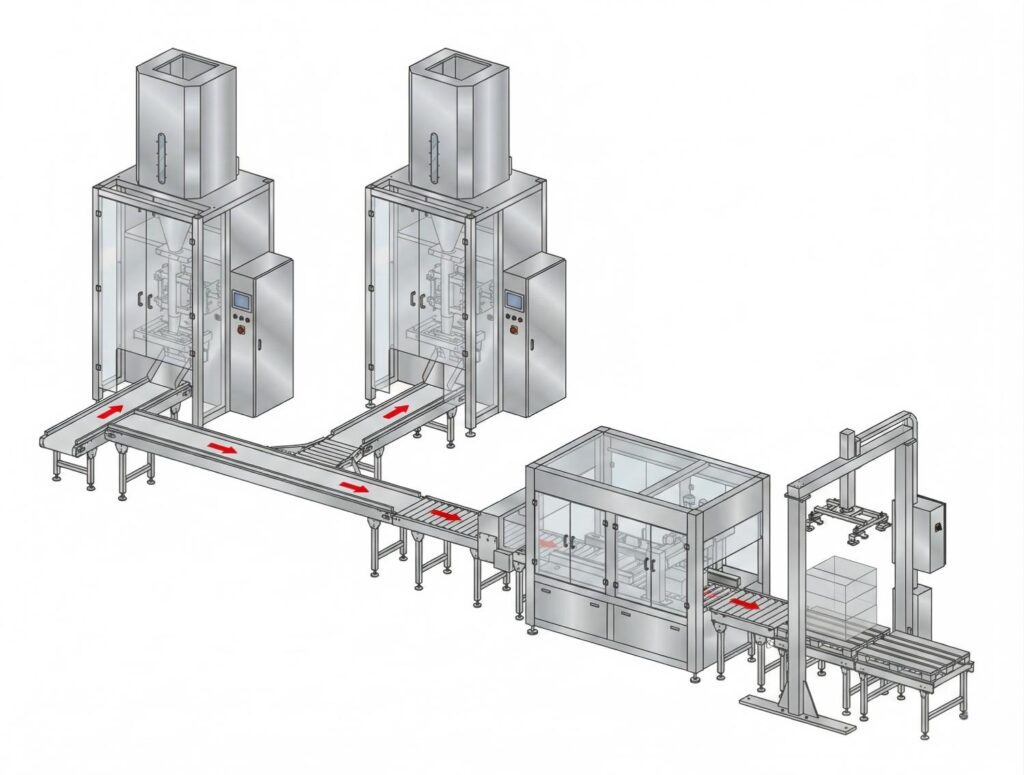

How does a complete popcorn packing line actually look?

A professional line flows from cooling and moisture stabilization to weighing, nitrogen-flushed bagging, and final inspection.

The standard configuration looks like this:

Popcorn Cooling → Moisture Control → Conveying → Multi-head Weigher → VFFS + Nitrogen → Check Weigher → Metal Detection → Case Packing.

For export-oriented factories, additional modules may include:

- Automatic carton erectors

- Robotic case packers

- Online oxygen testing stations

Why choose Lintyco for your popcorn packing solution?

We don’t just sell machines; we engineer complete systems focused on oxygen control, seal reliability, and long-term ROI.

At Lintyco, we specialize in high-precision complete packing lines. If your brand requires a longer shelf life, our custom dual-nozzle nitrogen flushing systems, oxygen residual detection modules, and high-barrier film compatibility testing ensure stable performance.

We also utilize high-accuracy temperature-controlled heat sealing systems to prevent oil contamination from compromising seal strength.

Our positioning is simple:

- European structural standards

- Competitive manufacturing cost

- Custom engineering support

- Scalable automation solutions

What are the technical hurdles you’ll face?

Success isn’t guaranteed just by buying a machine; you have to manage gas leakage, film barrier properties, bag inflation, and seal integrity.

- Gas Leakage: If your seal temperature or pressure is off by even a few degrees, nitrogen escapes.

- Incorrect Gas Ratio: It’s a “Goldilocks” problem—not too much, not too little.

- Insufficient Seal Strength: Popcorn oil contamination reduces heat-seal bonding strength.

- High OTR Film Selection: Poor-quality film allows oxygen migration even after flushing.

- Bag Inflation & Logistics: Over-inflated bags increase shipping volume and logistics costs.

How to choose the right solution for your business?

Start with your daily volume, target shelf life, and distribution radius.

- Step 1: Volume. Small batches (<500kg/day) may need semi-automatic solutions; industrial production (2000kg+/day) requires full automation.

- Step 2: Bag Style. Pillow for cost leadership; Doypack for premium positioning.

- Step 3: Shelf Life Target. More than 3–6 months? Nitrogen flushing + high-barrier film is mandatory.

- Step 4: Export or Domestic? Export markets demand stricter oxygen and seal validation.

- Step 5: Budget Planning. Choose modular systems to allow future expansion.

Is nitrogen flushing actually worth the extra cost?

Yes. While it typically adds about 8–15% to equipment investment, it significantly reduces product returns, improves brand reputation, and enables premium pricing.

For brands targeting supermarkets, cross-border e-commerce, or overseas distribution, nitrogen is not an upgrade—it is a risk-control strategy.

Think of it as insurance. Longer shelf life means wider distribution radius and less waste. In this industry, “crispy” is a currency.

FAQ about popcorn packaging

Q: Is nitrogen flushing necessary?

A: Yes, if you want shelf life beyond a few weeks or plan for export distribution.

Q: What O₂ level is acceptable?

A: Under 3% for standard retail; under 2% for premium positioning.

Q: Can VFFS machines integrate nitrogen systems?

A: Yes, it is a standard modular integration.

Q: Does nitrogen affect taste?

A: No. Nitrogen is inert and does not alter flavor.

Q: What film works best?

A: Metallized or multi-layer laminated films with low OTR and MVTR values.

Choosing a Long-Term Packaging Partner

- Popcorn is fragile, low-density, and oxygen-sensitive.

- Moisture control and high-barrier film selection are as important as nitrogen.

- Nitrogen flushing is the gold standard for maintaining <3% oxygen.

- VFFS machines are the best all-rounders for speed and cost efficiency.

- Expect an 8–15% investment increase for nitrogen systems—but expect longer shelf life and fewer returns.

Picking a packaging partner isn’t just about hardware, it’s about engineering control over oxygen, moisture, and sealing reliability.

Ready to stop selling stale popcorn?

Would you like me to create a custom ROI projection based on your target production volume and export market?