This guide is written for cereal manufacturers evaluating long-term packaging strategies—not for comparing machine specifications.

Choosing a cereal packing solution is not simply about purchasing a packaging machine.

For cereal manufacturers, co-packers, and brand owners, the real challenge lies in balancing product freshness, operational efficiency, sustainability requirements, and long-term cost control—often across multiple SKUs and packaging formats.

This guide explains how cereal packing solutions are actually selected in real production environments, based on engineering realities, operational trade-offs, and market expectations—not brochure specifications.

How Many Types of Cereal Packaging Are Commonly Used?

Bag-in-Box, Stand-Up Pouch, or Pillow Bag?

Each cereal packaging format addresses a different operational objective:

Bag-in-Box

- Strong shelf presence and stacking efficiency

- Requires high-integrity inner bag sealing to prevent moisture ingress

- Higher system complexity due to cartoning + bag forming synchronization

Stand-Up Pouch

- Excellent shelf appeal and premium positioning

- Suitable for granola, mixed grains, and value-added cereals

- Demands precise pouch handling and filling accuracy

Pillow Bag

- Cost-effective and high-speed

- Common for large-volume, price-sensitive SKUs

- Limited reseal functionality

The optimal cereal packing solution depends on distribution channel, shelf life target, and brand strategy, not just visual design.

Single-Serve vs Family-Size Cereal Packaging

Package size directly affects system design:

- Single-serve formats require higher dosing accuracy and often use multi-lane configurations to maintain throughput.

- Family-size packs prioritize speed, film efficiency, and stable long-run performance.

A well-designed cereal packing solution should support SKU expansion and format changes without full line replacement, preserving long-term flexibility.

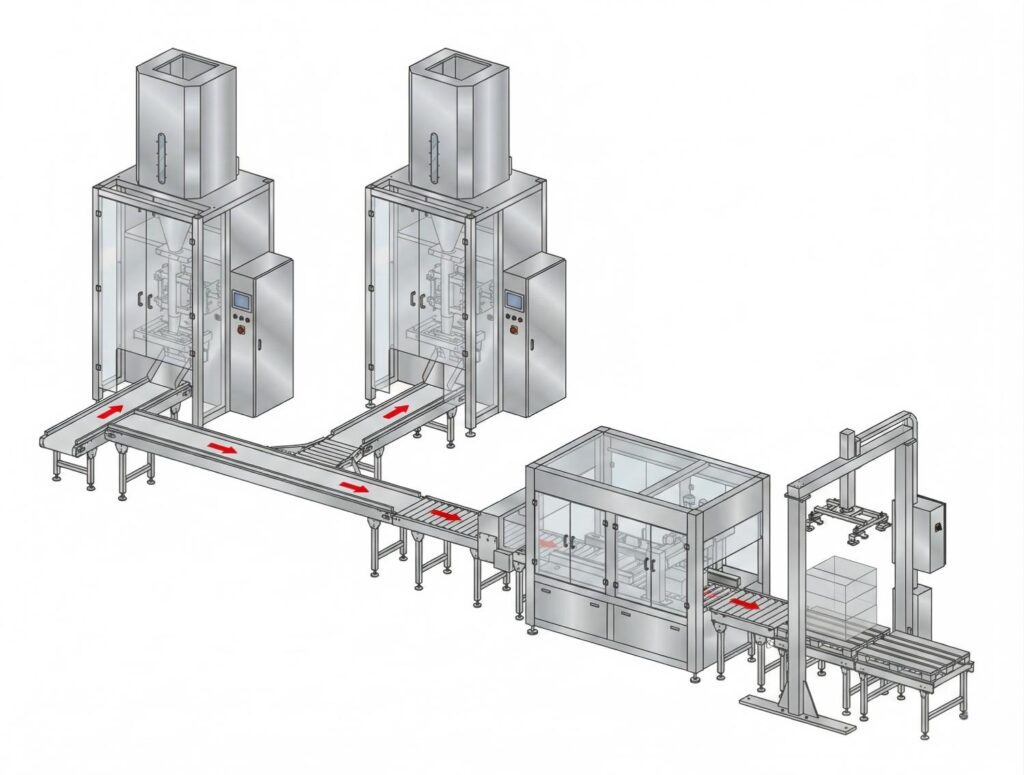

Equipment Is Only 40% of the Automatic Packing Solution

Packaging machines are essential—but they are not the entire system.

A complete cereal packing solution includes:

- Product feeding and handling Gentle elevation and controlled flow prevent breakage in flakes and clusters.

- Weighing system selection Multihead weighers suit mixed cereals and granola; linear weighers work for uniform grains.

- Film structure and sealing window control Film choice must align with machine sealing capability to ensure consistency.

- Nitrogen flushing strategy Reduces oxygen levels and extends shelf life, especially for fat-rich cereal blends.

- Line integration Upstream feeding and downstream cartoning must be synchronized to avoid bottlenecks.

Packaging material choice alone does not guarantee product protection. Operational data from cereal producers shows that seal quality and repeatability often have a greater impact on shelf life than film thickness. Even high-barrier materials can underperform if temperature, pressure, or dwell time drift during production.

A robust cereal packing solution treats sealing as a controlled process—not a passive step.

In practice, many cereal packaging failures attributed to “material issues” or “product instability” can be traced back to inconsistent sealing control rather than equipment limitations.

Reseal Features vs Initial Seal Integrity

From an engineering perspective, initial seal integrity and controlled headspace conditions deliver more predictable shelf-life performance than consumer-dependent reseal mechanisms.

For this reason, manufacturers often prioritize initial seal integrity and headspace management over relying on resealable features alone. From an engineering standpoint, maintaining low residual oxygen levels and effective moisture barriers at first seal delivers more predictable shelf-life performance than post-opening reseal behavior.

Packaging format decisions should therefore consider not only convenience, but also how much protection must be guaranteed before the package is opened.

Lintyco PACK Cereal Packing Solutions

As a system-level packaging solution provider, Lintyco PACK focuses on modular cereal packing solutions designed to adapt to different products, formats, and production scales—without locking manufacturers into rigid configurations.

Lintyco PACK provides modular cereal packing solutions designed to adapt to different cereal products, packaging formats, and production scales—without locking manufacturers into rigid configurations.

Vertical Form Fill Seal (VFFS) for Cereal Packaging

Vertical packaging machines are widely used for pillow bags and high-output cereal lines. Lintyco’s VFFS systems integrate seamlessly with multihead weighers, support nitrogen flushing, and deliver stable sealing performance for granular and flaked products.

Premade Pouch Packing Machines for Granules

For stand-up pouches and premium cereal products such as granola and mixed grains, Lintyco’s premade pouch packing machines offer reliable pouch handling, accurate filling, and compatibility with recyclable pouch structures.

Granule Packaging Industry Solutions

Manufacturers handling multiple grain-based products benefit from Lintyco’s granule packaging solutions, which emphasize fast changeovers, modular expansion, and consistent long-term operation.

Rather than supplying isolated machines, Lintyco focuses on system compatibility and line-level reliability, supporting sustainable production growth.

Buy Packaging Equipment or Outsource to a Co-Packer?

Outsourcing cereal packaging is often considered during early-stage production.

Co-packing is typically suitable when:

- Volumes are low or seasonal

- Market testing is ongoing

- Capital expenditure must be minimized short-term

Owning a cereal packing solution becomes advantageous when:

- Volumes stabilize and grow

- Multiple SKUs require frequent adjustments

- Long-term cost per unit becomes critical

For many cereal brands, the operational break-even point arrives earlier than expected once packaging volumes increase.

Sustainability in Cereal Packaging: What Actually Works

Sustainable cereal packaging introduces additional engineering complexity.

While recyclable and paper-based structures are increasingly requested, their performance must be evaluated against humidity resistance, sealing reliability, and transport durability. Operational feedback shows that some recyclable materials require narrower sealing tolerances and stricter process control to achieve performance comparable to traditional laminates.

Without appropriate machine capability, sustainability-driven material changes can unintentionally increase waste through seal failures or reduced shelf life. Effective sustainable cereal packing solutions balance material selection with equipment capability, rather than treating sustainability as a material-only decision.

How to Choosing the Right Cereal Packing Solution?

Before committing to a system, decision-makers should evaluate:

- Cereal type (flakes, granules, blends)

- Target shelf life and storage conditions

- Packaging format and size range

- Production speed requirements

- Sustainability and regulatory goals

- Capital budget and long-term operating cost

Across cereal production lines, a recurring lesson emerges: packaging failures are rarely solved downstream. Attempts to compensate with clips, secondary sealing, or inserts usually indicate that the primary packaging system is underperforming.

Frequently Asked Questions About Cereal Packaging

How do manufacturers keep cereal fresh without over-engineering packaging?

By aligning film barrier performance, sealing consistency, and headspace control with the product’s actual sensitivity to moisture and oxygen.

Is nitrogen flushing always necessary for cereal packaging?

Not always, but it significantly improves shelf life for premium or high-fat cereal products.

Can one cereal packing line handle multiple SKUs?

Yes—when the system is designed with flexible weighing, adjustable forming components, and modular integration.

What is the most common mistake when choosing a cereal packing solution?

Focusing solely on machine price instead of evaluating total system performance and long-term operating cost.

Conclusion

A cereal packing solution is not a single purchase—it is a production strategy.

Manufacturers who design packaging systems around real product behavior, operational constraints, and future growth consistently outperform those who select equipment based on specifications alone.