Let’s be honest: packing cacao powder is a challenge if you do not have the right equipment. It is extremely fine, generates dust easily, and is highly sensitive to moisture. Anyone who has seen cacao powder floating across a production floor understands the operational risks immediately.

To package it properly, you need a strategy that prioritizes precise dosing, dust-controlled operation, and reliable seal integrity.

Whether you are evaluating a standalone powder packing machine or planning a complete cacao powder packaging solution, this guide will help you understand what really matters from a technical and production standpoint.

What Is a Cacao Powder Packing Solution?

A cacao powder packing solution is not a single machine. It is a coordinated technical system designed to manage dosing, filling, sealing, and dust control as one integrated process.

Cacao powder behaves very differently from granules or whole products. Its fine particle size makes it prone to airborne dispersion, while moisture exposure leads to clumping and inconsistent filling. That is why general-purpose powder equipment often fails in cacao applications.

A professional cacao powder packaging solution typically includes:

- Automated feeding to maintain stable product flow

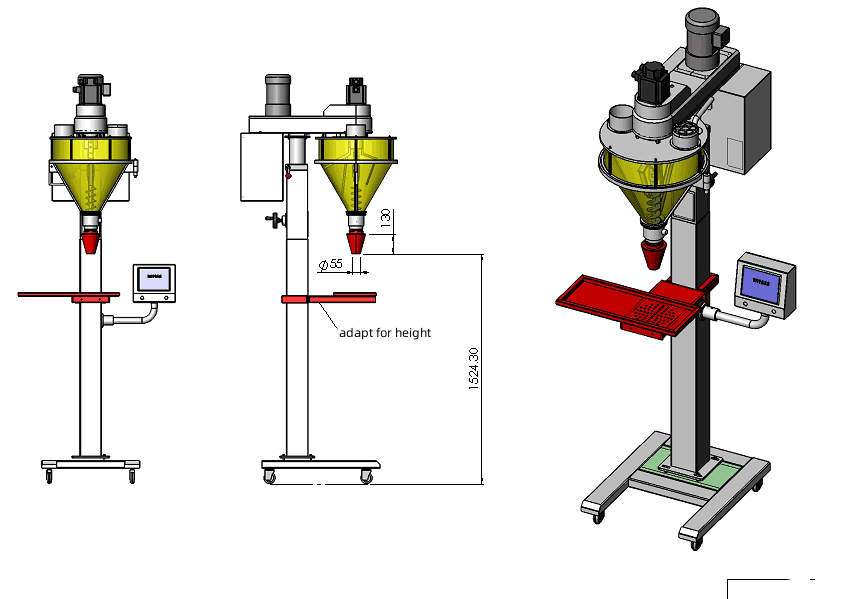

- Precision auger dosing to ensure consistent fill weights

- Integrated dust extraction to protect seals and operators

- Line-level integration for smooth, continuous operation

Which Cocoa Powder Packaging Machines Are Most Effective?

The right equipment depends largely on your packaging format, production objectives, and branding requirements. Below are the most commonly used machine types for cacao powder.

Is an Auger (Screw) Filler the Best Choice for Accuracy?

Yes. Auger fillers are widely regarded as the standard solution for fine powders such as cacao, coffee, and milk powder. By using a controlled screw mechanism, the system meters powder precisely while minimizing exposure to open air.

Key advantages include stable dosing performance and an enclosed filling environment that significantly reduces dust contamination.

Should You Use a VFFS or a Premade Pouch Machine?

Both formats are commonly used in cacao powder packaging, but they serve different goals.

VFFS (Vertical Form Fill Seal) machines create bags directly from roll film. They are typically chosen for efficient, continuous production and flexible bag sizing.

Premade pouch machines are often selected when visual presentation matters more. They allow for zipper closures, shaped pouches, and premium shelf appearance.

The decision usually comes down to production style versus branding priorities.

However, neither VFFS nor premade pouch systems are universally suitable for all cacao powder formulations. Powders with limited flowability, elevated fat content, or higher sensitivity to ambient humidity may require additional enclosure, agitation, or environmental control. Without these considerations, even well-engineered machines can experience unstable dosing or compromised seal quality.

What About Sachet and Stick Pack Formats?

Sachet and stick pack machines are designed for single-serve portions. They are frequently used for instant drink mixes, sample packs, or travel-friendly products.

For cacao powder applications targeting convenience or trial usage, multi-lane stick pack systems are a practical and scalable solution.

How a Complete Cocoa Powder Packing Line Is Designed

Designing a full cacao powder packing line is about managing product flow from raw intake to final packed output without interruption or contamination.

Rather than focusing on individual machines, experienced integrators evaluate the entire process flow. A typical solution may include:

- Controlled powder feeding from storage or hopper

- Auger-based dosing for consistent filling

- Active dust management to protect seal quality

- Reliable sealing using thermal or ultrasonic methods

- Optional integrations such as gas flushing, weight verification, and product inspection

Dust control plays a particularly critical role. Any residual powder in the sealing area can compromise package integrity and shelf life.

In practical production environments, sealing failures are frequently traced back not to sealing temperature or pressure, but to residual cacao powder trapped in the seal area. This is a widely observed issue in fine powder applications and is a key reason why dust extraction and controlled filling are treated as core system requirements rather than optional features.

Why Manufacturers Choose Lintyco for Powder Packaging Integration

Lintyco focuses on building complete powder packaging systems rather than supplying isolated machines. Each solution is configured around the customer’s product behavior, packaging format, and factory layout.

Lintyco’s capabilities include:

- Powder packaging machines designed for fine and dusty materials

- Premade pouch systems for retail-focused packaging

- Vertical form fill seal systems for continuous production

- Horizontal form fill seal solutions for specific pouch or sachet formats

The emphasis is always on system compatibility, clean operation, and long-term reliability.

For example, A specialty cacao roastery in California faced recurring challenges with inconsistent fill weights and dust accumulation that caused frequent production interruptions. The facility, producing 2,000 packages per day with 250-gram portions, experienced customer complaints related to a dosing variance of ±2.5 grams, while powder build-up in the sealing area resulted in 2-3 unplanned stoppages per week.

After implementing a customized servo-driven auger filler with integrated dust extraction and ±0.5% precision weight verification, the roastery observed substantial operational improvements. Fill weight variance was reduced to ±0.8 grams, seal-related issues were eliminated entirely with zero dust-related stoppages over 6 months, and product shelf life extended by 2 months due to improved moisture control. The system achieved ROI within 18 months, with installation completed in 4 weeks and optimization finalized in 2 weeks.

How to Select the Right Cacao Powder Packing Equipment

Before investing in cacao powder packaging equipment, it is important to evaluate functional fundamentals rather than surface-level features.

Key factors to assess include:

- Dosing consistency under real production conditions

- Food-grade construction suitable for powder handling

- Effective dust containment at filling and sealing points

- Compatibility with future automation or inspection upgrades

Typical Technical Considerations

| Category | What to Evaluate |

|---|---|

| Dosing performance | Stability and repeatability |

| Machine construction | Food-grade stainless steel |

| Dust management | Enclosed filling and extraction |

| Packaging formats | Compatibility with current and future needs |

| Expansion options | Inspection, flushing, coding |

Frequently Asked Questions About Cacao Powder Packing Solution

What is a cacao powder packing solution?

It is an integrated system that combines dosing, filling, sealing, and dust control specifically designed for fine cacao powder.

How do I choose the right machine?

Start with your packaging format, required output level, and how effectively the system manages dust during operation.

How can dust be prevented from affecting seal quality?

An enclosed filling design combined with active dust extraction at critical points is essential.

Conclusion

Focus on next point and go ahead.

- Cacao powder requires specialized handling due to its fine texture

- Dust control is critical for seal integrity and hygiene

- Auger fillers are the preferred dosing method for accuracy

- Packaging format selection should balance efficiency and branding

- Equipment quality and system integration matter more than isolated features

Ready to improve your cacao powder packaging process?

A properly designed system can dramatically reduce dust, improve consistency, and protect product quality. Contact our engineering team to evaluate a solution tailored to your production goals.