Global pet food packaging market sees unprecedented growth. It hit $12.97 billion on 2024. By 2034, it’s projected to reach $21.74 billion. That’s an robust CAGR of 5.3%. This surge comes from rising pet ownership, premiumization trends, and demand for convenient, sustainable packaging.

Modern pet food packaging machines evolved from simple bagging devices into AI – driven systems. They deliver precision, efficiency, sustainability for firms—small businesses to multinationals.

This analysis spots top 5 pet food packaging machines driving innovation. They’re evaluated by production capacity (up to 3,000 bags hourly), filling accuracy (±0.3% precision), sustainability, cost – effectiveness. From high – speed vertical form fill seal systems to premium premade pouches, these machines lead packaging tech for dry kibble, wet food, treats, specialized pet nutrition.

1. Bosch Sigpack VPF Series (Germany)

Bosch Sigpack VPF shows German engineering excellence in flat pouch packaging. This system offers unmatched flexibility. Production scales from 2–12 lanes. In multi – lane setups, it hits speeds up to 440 bags per minute.

Modular Innovation

Sigpack VPF’s modular design lets makers adapt fast to market shifts. Each lane works independently (own dosing chamber, product stock). It allows simultaneous packaging of different products (e.g., pet treat flavors, protein sources).

Technical highlights:

- Rapid Format Changes: 1 – minute switch between pouch sizes

- Individual Lane Control: Independent dosing for max flexibility

- Precision Dosing: ±1% accuracy (strong powder handling)

- German Components: High – quality European electronics (max reliability)

Investment Considerations

Priced $100,000–$300,000, Sigpack VPF targets medium – to – large ops needing premium performance, flexibility. Its modular design allows phased investment—start with few lanes, expand as production grows.

2. ROVEMA BVC Series VFFS (Germany)

ROVEMA’s BVC Series is the gold standard in vertical form fill seal tech for pet food. Built for 500g–5kg products, these German systems excel at bulk dry pet food packaging (reliability, precision).

Advanced VFFS Tech

BVC series uses innovative Stabilo Seal bags (zip closures). It gives consumers resealable packaging (keeps food fresh). The system hits 40 bags per minute (±1% filling accuracy). It’s ideal for medium – to – high – volume ops.

Key features:

- Reclosable Packaging: Zip – closure for consumer convenience

- Particle Handling: Processes various kibble sizes, treat formats

- Automated Operation: Little operator intervention needed

- Hygienic Design: Food – grade stainless steel build

- Energy Efficiency: Optimized for sustainable production

Market Positioning

Priced $80,000–$150,000, ROVEMA systems offer premium German engineering, global support. The firm’s 60 + years in packaging tech ensures reliable performance, deep expertise.

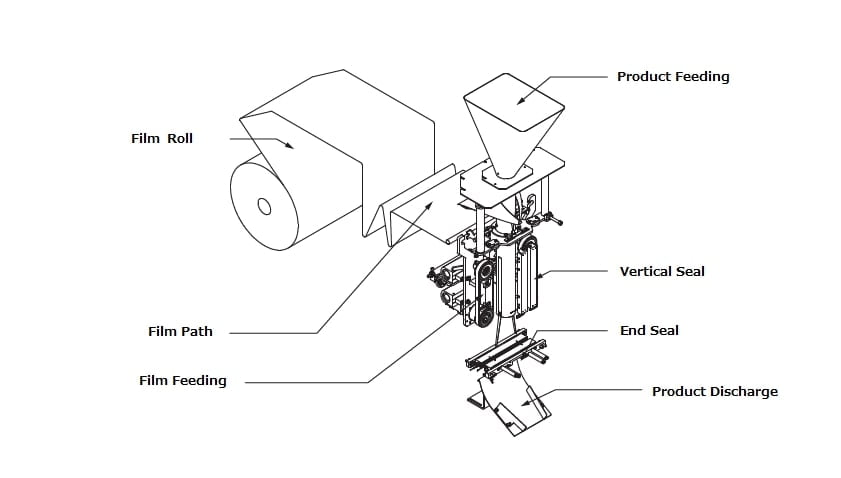

3. Lintyco Pack Rotating Premade Pouch Packaging System (China)

Lintyco Pack is a top cost – effective pick for small – to – medium firms wanting premium pet food packaging. It has 15 + years’ industry experience. Over 40,000 machines are installed across 190 + countries. Lintyco Pack becomes a trusted leader in automated packaging tech.

Technical Excellence & Innovation

Lintyco Pack Rotating Premade Pouch System delivers strong performance. Speeds hit 80 bags per minute. It has industry – leading ±0.5% filling accuracy. Built with SS304 stainless steel, the system meets top food – grade standards. It supports pouch formats like zipper pouches, stand – up pouches, four – side seal bags.

Key tech perks:

- Advanced Servo – Driven Tech: Cuts waste by 12% vs clutch systems (precise film control)

- Integrated Vision Systems: Detect incomplete pouch openings (defect rates under 0.1%)

- Nitrogen Flushing: Vital for oxygen – sensitive products, longer shelf life

- Automated CIP (Clean – in – Place): Ensures hygiene between production runs

- Multi – Product Flexibility: Handles dry kibble, treats, wet food, specialized nutrition

Cost – Effectiveness & ROI

Priced at $15,000–$50,000, Lintyco Pack systems offer great value. ROI typically happens in 12–18 months. The firm’s pricing targets cost – conscious makers. It keeps premium quality, offers full after – sales support.

Download Packaging Equipment ROI Calculator Here.

Global Support Network

Lintyco Pack’s service includes 24/7 tech support, certified techs worldwide, ample spare parts. The firm’s customer commitment shows in its 3.7/5 star satisfaction rating. It scores high for value – for – money (4.5/5).

4. MF TECNO MF POUCH 3000 (Italy)

MF TECNO’s MF POUCH 3000 delivers high – speed packaging. It hits 3,000 bags hourly (50 bags per minute). This Italian system specializes in flexible pouches (doy packs, totani, stand – up styles).

Versatility & Performance

MF POUCH 3000 handles diverse pet food—5g treats to 30kg bulk. Its max format flexibility lets processors switch product lines, pouch sizes with little downtime.

Technical specs:

- High Production Capacity: Up to 3,000 bags hourly

- Format Flexibility: Multiple pouch styles, sizes

- Precision Control: ±0.8% filling accuracy

- Hygienic Standards: Available in full AISI 304 stainless steel

- Integration: Works with palletizing, wrapping systems

Priced $120,000–$200,000, it targets medium – to – large ops needing versatile, high – speed packaging.

5. Tetra Pak Tetra Recart Line (Sweden)

Tetra Pak’s Tetra Recart system revolutionizes wet pet food packaging with sustainable cartons. It hits 30,000 units hourly (±0.3% accuracy). This system meets demand for eco – friendly packaging.

Sustainability Leadership

Tetra Recart has 85% lower climate impact than cans, 20% less than pouches. It uses 71% renewable content (from responsibly managed forests). This matches consumer demand for sustainable pet food packaging.

Operational perks:

- Logistics Efficiency: 50% more packages per truck load (vs cans)

- Storage Optimization: 10:1 empty package storage ratio

- Shelf Impact: 25–40% more shelf space use

- E – commerce Friendly: Optimized for online retail

- Premium Positioning: Rectangular format (billboard effect)

Premium Investment

Priced $500,000–$1,500,000, Tetra Recart targets large – scale makers, co – packers for premium brands. The cost reflects advanced tech, sustainability, full support.

Performance Comparison & Market Analysis

Pet food packaging machinery serves all operation scales—from Lintyco Pack’s $15k systems to Tetra Pak’s $1.5M+ lines. Each targets specific market segments, needs.

Market Segmentation

- Small – to – Medium Firms: Lintyco Pack’s rotating pouches offer great price – to – performance, full support. ROI hits in 12–18 months. They grow with your business.

- Mid – tier Makers: ROVEMA’s BVC or MF TECNO balance performance, cost. These European systems offer premium reliability at moderate cost.

- Large – Scale Ops: Bosch’s modular systems or Tetra Pak’s high – speed lines prioritize throughput, advanced features over initial cost.

Industry Trends & Future Outlook

Tech Advancements

Modern pet food packaging machines add Industry 4.0 tech—IoT, predictive maintenance, AI quality control. Lintyco Pack leads with smart solutions (real – time monitoring, automated quality checks).

Sustainability Focus

Eco – concerns drive innovation. Systems like Tetra Recart use 70% renewable materials. Mondi offers recyclable mono – material solutions. This lets forward – thinking makers stand out, meet consumer expectations.

E – commerce Adaptation

Online pet food sales need tough packaging (handles shipping, keeps product safe). Machines must adapt to formats—single – serve to bulk.

ROI Analysis

Productivity Gains

Automated systems cut labor by 60–80%. They run 5–10x faster than manual processes. Advanced systems hit 95%+ efficiency, eliminate human error.

Quality Improvements

Precision filling (±0.5%, like Lintyco Pack) cuts product waste, meets regulations. Advanced sealing prevents leaks, extends shelf life (key for pet food quality).

Cost Optimization

Choose equipment based on production, growth, market. Lintyco Pack’s approach includes ROI analysis, custom solutions for each customer.Download Packaging Equipment ROI Calculator Here.

Conclusion

Picking the right pet food packaging machine is key to manufacturing success, competitiveness. The five systems—led by Lintyco Pack’s innovation plus premium European brands—represent top packaging tech for today’s pet food market.

Lintyco Pack’s rotating premade pouch machine stands out for speed, accuracy, versatility, cost – effectiveness. It’s ideal for makers wanting premium packaging, reliable performance, full support. With 15 years’ experience, global service, innovation focus, Lintyco Pack is a top pet food packaging partner.

When evaluating equipment, consider production, product, packaging, budget, growth. Lintyco Pack’s experts help pick, configure the best system for your needs.

The pet food packaging industry evolves—driven by sustainability, automation, changing consumer tastes. Choose the right gear today (like Lintyco Pack’s systems) to succeed tomorrow. Deliver the quality, convenience pet owners want.