Als kleiner Kaffeeröster haben Sie wahrscheinlich zehn verschiedene Rollen inne. Sie sind Chefröster, Qualitätskontrollleiter, Marketingleiter und manchmal sogar Lieferant. Angesichts all dieser Aufgaben erscheint Ihnen die Verpackung möglicherweise wie eine weitere überwältigende Entscheidung.

Aber hier ist die Sache: Flexible Verpackungen könnten der entscheidende Faktor für Ihr Kaffeegeschäft seinEs geht nicht nur darum, Ihre Bohnen frisch zu halten (obwohl das unglaublich gut funktioniert). Es geht um Kosteneinsparungen, Markenwirkung und darum, Ihren Kunden genau das zu geben, was sie wollen – und dabei Ihr Leben um einiges einfacher zu machen.

Was genau ist flexible Verpackung?

Stellen Sie sich flexible Verpackungen als das Schweizer Taschenmesser der Kaffeewelt vor. Im Gegensatz zu den starren Dosen oder Gläsern, die Ihr Großvater vielleicht benutzt hat, bestehen flexible Verpackungen aus leichten, anpassungsfähigen Materialien wie Kunststofffolien, Folien oder Karton. Wir sprechen von Standbeutel, Flachbodenbeutel, Seitenfaltenbeutel, Und Kraftpapier-Optionen das sich buchstäblich Ihren Bedürfnissen anpassen kann.

Das Schöne an flexiblen Verpackungen ist ihre Vielseitigkeit. Es ist, als hätten Sie eine Verpackungslösung, die ihre Form verändern kann – mal ein eleganter Standbeutel für Ihre hochwertigen Single-Origin-Produkte, mal ein Seitenfaltenbeutel für Ihre Großhandelskunden.

Warum kleine Röster verrückt nach flexiblen Verpackungen sind

1. Es wird Ihr Budget nicht sprengen

Lassen Sie uns kurz über Zahlen sprechen. Flexible Verpackungen kosten typischerweise 30-40% weniger als starre Alternativen. Wenn Sie bereits in hochwertige Bohnen, Röstgeräte und den Aufbau Ihrer Marke investieren, können Sie jeden Dollar, den Sie bei der Verpackung sparen, in das investieren, was wirklich zählt – die Zubereitung von unglaublichem Kaffee.

Darüber hinaus bieten die meisten Anbieter flexibler Verpackungen niedrigere Mindestbestellmengen (MOQs), was bedeutet, dass Sie neue Designs oder saisonale Verpackungen testen können, ohne sich auf Tausende von Einheiten festlegen zu müssen.

2. Ihr Kaffee bleibt länger frisch

Frischer Kaffee ist alles, oder? Flexible Verpackungen zeichnen sich durch mehrere wichtige Eigenschaften aus:

- Einweg-Entgasungsventile: Diese kleinen Helden lassen CO2 aus frisch geröstetem Kaffee entweichen und halten gleichzeitig Sauerstoff fern. Es ist, als ob Sie Ihrem Kaffee eine atmungsaktive Barriere verleihen, die nur in eine Richtung funktioniert.

- Hochbarrierematerialien: Mehrschichtige Verpackungen blockieren Feuchtigkeit, Licht und Sauerstoff – die drei Feinde des großartigen Kaffeegeschmacks.

- Wiederverschließbare Reißverschlüsse: Ihre Kunden können ihren Kaffee zwischen den Brühvorgängen frisch halten.

3. Platzsparender Speicher, der wirklich wichtig ist

Wenn Sie in einer kleinen Rösterei oder einer Großküche arbeiten, wissen Sie, dass jeder Quadratmeter zählt. Flexible Verpackungen benötigen deutlich weniger Lagerraum als starre Behälter, sowohl im leeren als auch im gefüllten Zustand. Einige Röster berichten von Einsparungen von bis zu 60% auf Speicherplatz nach der Umstellung auf flexible Verpackungen.

4. Ihre Marke kann endlich glänzen

Hier wird flexible Verpackung wirklich spannend. Sie haben fünf bedruckbare Oberflächen Auf den meisten Beuteln (Vorder-, Rückseite, zwei Seiten und Boden) finden Sie unzählige Möglichkeiten, Ihre Geschichte zu erzählen. Ob Sie die Entstehungsgeschichte Ihres Kaffees erzählen, Zubereitungshinweise geben oder einfach nur einen Blickfang im Regal schaffen möchten – flexible Verpackungen bieten Ihnen die perfekte Grundlage dafür.

5. Nachhaltigkeit, die Ihre Kunden wirklich wollen

Den heutigen Kaffeetrinkern ist die Umwelt wichtig, und flexible Verpackungen tragen auf verschiedene Weise zur Nachhaltigkeit bei:

- Recycelbare Optionen sind weit verbreitet

- Kompostierbare Materialien aus pflanzlichen Quellen hergestellt

- Reduzierte Transport-Emissionen durch geringeres Gewicht

- Geringerer Gesamtmaterialverbrauch im Vergleich zu starren Verpackungen

Die Art der flexiblen Verpackung

Perfekt für Einzelhandelskunden, diese sind Ihre Anlaufstelle für Beutel von 12 oz bis 2 lb. Sie sehen im Regal professionell aus, funktionieren hervorragend mit wiederverschließbaren Reißverschlüssen und sind für die Kunden leicht zu handhaben.

Flachbodenbeutel

Diese verleihen Ihnen ein hochwertiges, kastenartiges Aussehen mit unglaublicher Stabilität. Sie sind ideal für Spezial- oder Geschenkverpackungen und bieten mehr Platz für Ihre Marke als herkömmliche Beutel.

Seitenfaltenbeutel

Die Arbeitspferde der Kaffeewelt. Ideal für Großmengen (ab 1 kg) und Großhandelskunden. Sie sind kostengünstig und lassen sich effizient für den Versand verpacken.

Kraftpapiertüten

Wenn Sie den handwerklichen, umweltfreundlichen Look wünschen, sorgen Kraftpapiertüten mit Barriere-Innenfutter für Authentizität und schützen gleichzeitig Ihren Kaffee.

Lintyco Pack: Ihr Partner für Verpackungsautomatisierung

Und jetzt wird es für wachsende Röster richtig interessant. Wenn Sie mehr als ein paar hundert Pfund pro Woche verpacken, haben Sie wahrscheinlich festgestellt, dass das manuelle Befüllen der Säcke zu einem Engpass in Ihrem Betrieb wird.

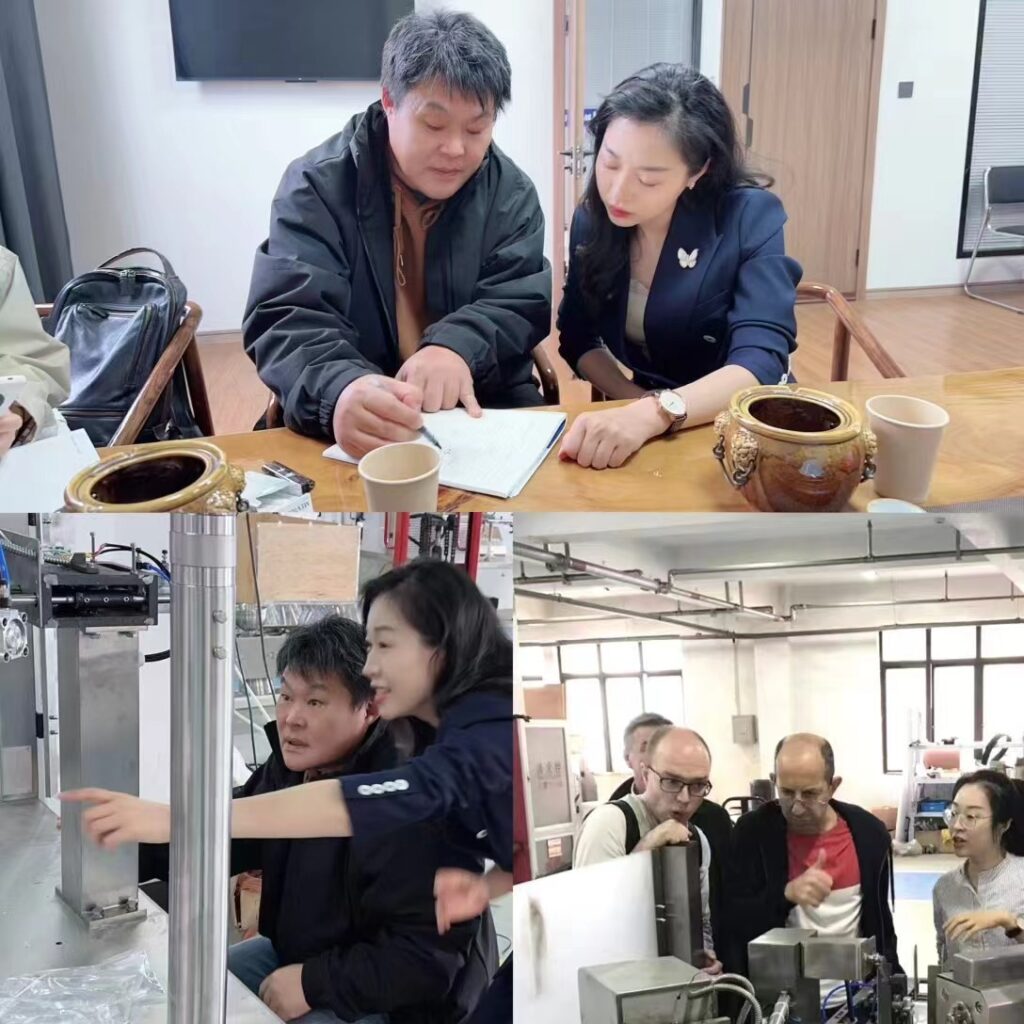

Hier ist Lintyco-Packung kommt ins Spiel. Wir sind ein chinesischer Hersteller, der still und leise die Verpackungsanlagen für kleine bis mittelgroße Röster weltweit revolutioniert hat.

Laden Sie hier den ROI-Rechner für Verpackungsmaschinen herunter.

Was macht Lintyco Pack so besonders?

Lintyco-Packung ist seit rund 15 Jahren im Verpackungsgeschäft tätig und verfügt über mehr als 40.000 Maschinen in 190 Ländern. Für Sie als kleiner Röster ist Folgendes wichtig:

- Fokus auf flexible Verpackungen: Ihre Maschinen funktionieren perfekt mit allen Verpackungsarten, über die wir gesprochen haben

- Geeignet für kleine Chargen: Ausrüstung für Produktionsraten von 20-80 Beuteln pro Minute

- Erschwingliche Preise: Typischerweise 30-40% weniger als europäische Wettbewerber

- All-in-One-Lösungen: Integrierte Entgasungsventilanwendung, Stickstoffspülung und Abdichtung

Kaffeespezifische Ausrüstung von Lintyco

| Maschinentyp | Am besten für | Geschwindigkeit | Preisklasse |

|---|---|---|---|

| LTC8 Vorgefertigter Beutel-Rotations | Standbeutel mit Ventilen | 20-60 Beutel/min | $20k-$55k |

| BG400 VFFS | Kleine Sachets und Proben | Bis zu 100 Beutel/min | $12k-$38k |

| Schneckenpulverfüller + VFFS | Gemahlener Kaffee in Kissen-/Seitenfaltenbeuteln | 40-80 Beutel/min | $10k-$48k |

Der Realitätscheck zum Lintyco Pack

Seien wir mal ganz ehrlich – Lintyco Pack ist nicht perfektSie erhalten hochwertige Geräte zu einem tollen Preis, der Nachteil besteht jedoch darin, dass der Support aus China kommt (Hallo, Zeitzonenprobleme) und Sie mit einigen grundlegenden Problemen bei der Fehlerbehebung vertraut sein müssen.

Lintyco bietet jedoch:

- WhatsApp-Support rund um die Uhr mit englischsprachigen Technikern

- Video-Inbetriebnahme um Sie zum Laufen zu bringen

- Ferndiagnose über PLC-Login

- Umfangreiche Ersatzteilpakete um Ausfallzeiten zu minimieren

4 Schritte für einen Kaffeeverpackungsplan

Schritt 1: Bewerten Sie Ihren aktuellen Bedarf

- Wie viele Säcke füllen Sie pro Tag?

- Welche Größen sind bei Ihren Kunden am beliebtesten?

- Planen Sie eine Expansion in den Großhandel?

Schritt 2: Klein anfangen

Beginnen Sie mit flexible Verpackungen für Ihre Einzelhandelsprodukte. Testen Sie unterschiedliche Stile mit kleinen Bestellungen, um zu sehen, was bei Ihren Kunden ankommt.

Schritt 3: Automatisierung in Betracht ziehen

Wenn Sie täglich mehr als 200 Säcke manuell befüllen, sollten Sie ernsthaft über Verpackungsanlagen nachdenken. Allein die Arbeitsersparnis kann die Investition innerhalb von 12 bis 18 Monaten rechtfertigen.

Schritt 4: Wachstum planen

Wählen Sie Verpackungslieferanten und -ausrüstung, die mit Ihrem Unternehmen wachsen können. Wenn Sie jetzt mit flexiblen Verpackungen beginnen, können Sie später die Automatisierung vereinfachen.

Häufig gestellte Fragen

F: Wie lange bleibt Kaffee in flexiblen Verpackungen frisch?

A: Hochwertige flexible Verpackungen mit geeigneten Barriereeigenschaften und Entgasungsventilen können gerösteten Kaffee frisch halten für 6-12 Monate bei richtiger Lagerung. Der Schlüssel liegt in der Wahl einer Verpackung mit ausreichender Sauerstoff- und Feuchtigkeitsbarriere.

F: Kann ich flexible Verpackungen bei kleinen Bestellmengen individuell anpassen?

A: Ja! Die meisten Anbieter flexibler Verpackungen bieten individuelle Anpassungen mit Mindestbestellmengen von nur 1.000-5.000 Stück, wodurch es auch für kleine Röster erschwinglich wird. Einige Anbieter bieten sogar Digitaldruck für noch kleinere Auflagen an.

F: Sind Entgasungsventile wirklich für jeden Kaffee notwendig?

A: Für frisch gerösteten Kaffee, absolut. Kaffee gibt nach dem Rösten noch Tage lang CO2 ab, und ohne Entgasungsventil könnten sich Ihre Beutel aufblähen oder platzen. Das Ventil verhindert außerdem das Eindringen von Sauerstoff, wodurch das Aroma erhalten bleibt.

F: Wie viel kann ich durch die Umstellung auf flexible Verpackungen einsparen?

A: Die meisten kleinen Röster sehen 25-40% Kosteneinsparungen im Vergleich zu starren Verpackungen. Weitere Einsparungen ergeben sich durch den geringeren Lagerraum, niedrigere Versandkosten und weniger Arbeitsaufwand bei der Handhabung.

F: Wie lange dauert die Lieferung von Lintyco Pack-Geräten?

A: Standardmaschinen werden normalerweise in 30-45 Tage, wobei Sonderkonfigurationen etwa 3 Wochen länger dauern. Die Transitzeit in die USA beträgt normalerweise 22–28 Tage und nach Europa 30–35 Tage.

F: Sind flexible Verpackungen wirklich nachhaltiger?

A: Das kann je nach den gewählten Materialien der Fall sein. Flexible Verpackungen verwenden typischerweise 40-50% weniger Material als starre Alternativen und hat aufgrund des geringeren Versandgewichts einen geringeren CO2-Fußabdruck. Achten Sie auf recycelbare oder kompostierbare Optionen, um den Umweltnutzen zu maximieren.

F: Können in flexiblen Verpackungen unterschiedliche Kaffeesorten verarbeitet werden?

A: Absolut. Flexible Verpackungen eignen sich hervorragend für ganze Bohnen, gemahlenen Kaffee und sogar Cold Brew-Konzentrat. Der Schlüssel liegt in der Wahl der richtigen Barriereeigenschaften und Ventilsysteme für Ihr spezifisches Produkt.

F: Woher weiß ich, ob ich für die Verpackungsautomatisierung bereit bin?

A: Erwägen Sie die Automatisierung, wenn Sie manuelles Befüllen von mehr als 200 Säcken pro Tag, wenn Probleme mit der gleichbleibenden Qualität auftreten oder wenn die Arbeitskosten einen erheblichen Teil Ihrer Verpackungskosten ausmachen.

F: Worauf sollte ich bei der Auswahl eines Lieferanten für flexible Verpackungen achten?

A: Zu den wichtigsten Faktoren zählen die Barriereleistung, Anpassungsmöglichkeiten, flexible Mindestbestellmengen, Lebensmittelzertifizierungen und nachhaltige Materialoptionen. Berücksichtigen Sie auch die Erfahrung mit kaffeespezifischen Anforderungen wie Entgasungsventilen.

F: Wie berechne ich den ROI für Verpackungsanlagen?

A: Berücksichtigen Sie die aktuellen Arbeitskosten, das prognostizierte Volumenwachstum, Einsparungen bei den Verpackungskosten und Qualitätsverbesserungen. Die meisten Röster sehen einen ROI innerhalb 12-24 Monate beim Übergang von manueller zu automatisierter Verpackung.

Das Fazit

Flexible Verpackungen sind nicht nur ein Trend – sie werden zum Standard für clevere Kaffeeröster, die Qualität, Kosten und Kundenzufriedenheit in Einklang bringen wollen. Ob Sie 50 oder 500 Beutel pro Woche befüllen – es gibt eine flexible Verpackungslösung, die Ihr Unternehmen wachsen lässt.

Und wenn Sie bereit sind, den nächsten Schritt in Richtung Automatisierung zu gehen, Unternehmen wie Lintyco-Packung machen professionelle Verpackungsgeräte für kleine und mittlere Röster weltweit zugänglich.

Die Kaffeebranche ist wettbewerbsintensiver als je zuvor, aber mit dem richtigen Verpackungsansatz können Sie Ihr Produkt schützen, Ihre Marke präsentieren und ein Unternehmen aufbauen, das für alles bereit ist, was als Nächstes kommt.

Sind Sie bereit, flexible Verpackungsoptionen für Ihre Rösterei zu erkunden? Fordern Sie zunächst Muster bei Verpackungslieferanten an und scheuen Sie sich nicht, verschiedene Stile mit Ihren Kunden zu testen. Ihre perfekte Verpackungslösung gibt es – und Ihr zukünftiges Ich (und Ihr Rücken) werden es Ihnen danken, wenn Sie früher oder später umsteigen.